Mastars leverages cutting-edge 3D printing technology to transform digital designs into functional prototypes and end-use products. We utilize industry-standard methods like SLA, SLS, and FDM to achieve exceptional accuracy and surface finish. This versatility makes us a preferred partner for industries ranging from aerospace to medical devices.

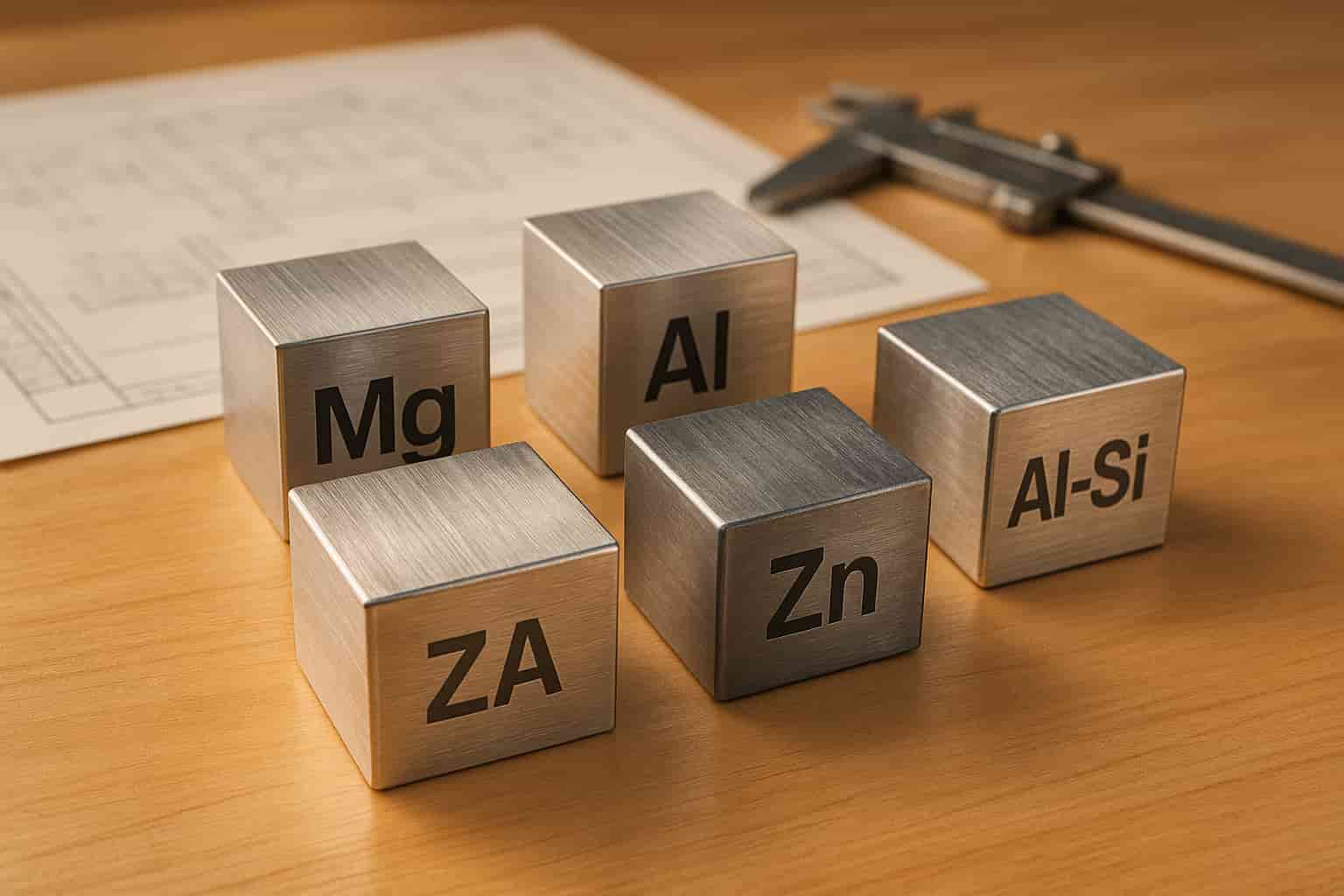

Our 3D print solutions prioritize material diversity, including engineering-grade resins, nylon, and metal alloys. Clients receive robust components tailored to mechanical requirements and environmental conditions. This flexibility is critical for applications demanding durability and performance under stress.

Speed-to-market is accelerated through Mastars' streamlined 3D printing service workflow. From file submission to delivery, we maintain rigorous quality checks at every stage. Australian and European clients enjoy reduced lead times without compromising on part integrity.

For complex projects requiring iterative testing, our rapid prototyping services offer unmatched efficiency. Functional prototypes validate designs before mass production, saving time and resources. This approach aligns with best practices highlighted in industry resources such as Engineering.com's guide to prototyping.

Mastars supports custom 3D printing projects with comprehensive design optimization assistance. Our engineers analyze models for manufacturability, suggesting enhancements to reduce costs and improve functionality. This collaborative process ensures client satisfaction across diverse sectors.

Sustainability is embedded in our additive manufacturing processes through material recycling and waste reduction. We adhere to eco-friendly practices without sacrificing part quality or structural performance. This commitment resonates strongly with environmentally conscious markets in Europe and Australia.

Cost-effectiveness defines our online 3D printing service, enabling startups and enterprises alike to access top-tier manufacturing. Competitive pricing models scale with project complexity and volume requirements. Clients achieve lower per-part costs while maintaining high standards.

Multi-material 3D printing capabilities allow for intricate assemblies consolidated into single components. This reduces assembly time and minimizes potential failure points in critical systems. Industries such as automotive and consumer electronics benefit from these innovations.

Mastars' dedication to excellence is evident in our compliance with international quality certifications, including ISO 9001. Each project undergoes meticulous inspection to ensure dimensional accuracy and material properties. Trusted by clients worldwide, we uphold the highest production standards.

For insights into additive manufacturing trends, refer to ASTM International's standards. These guidelines inform our processes and reinforce reliability for clients seeking certified manufacturing partners.

End-to-end solutions encompass post-processing options like sanding, painting, and annealing. Components receive finishing touches that enhance aesthetics and functionality. This full-service approach distinguishes Mastars as a holistic manufacturing provider.

Localized support for Australian and European clients includes dedicated communication channels and logistics coordination. We simplify offshore manufacturing with responsive service and transparent project management. Time zone differences are managed through efficient workflows.

Explore the future of manufacturing with Mastars' expert 3D print solutions. Contact us to discuss your project requirements and receive a competitive quote. Experience seamless manufacturing backed by technical proficiency and customer-centric values.