Mastars uses CNC technology to make prototypings and functional parts, providing customers with rapid prototyping services and high-precision parts production.Mastars has the world's leading CNC machine tools and leads the industry in CNC processing industry.

1. Simulation of stamping and forming process (CAE) plays a more prominent role

In recent years, with the rapid development of computer software and hardware, the simulation technology of stamping and forming process (CAE) is playing an increasingly important role. In the United States, Japan, Germany and other countries, CAE technology has become a necessary part of the mold design and manufacturing process, and is widely used to predict forming defects, optimize the stamping process and mold structure, improve the reliability of mold design, and reduce the time of mold trial.

The application of CAE technology can greatly save the cost of mold trial, shorten the development cycle of stamping mold, and has become an important means to ensure the quality of the mold.

2. mold three-dimensional design status to consolidate

Mold three-dimensional design is an important element of digital mold technology, is to achieve the integration of mold design, manufacturing and inspection of the foundation. Japan Toyota, the United States General Motors and other companies have realized the three-dimensional design of the mold, and achieved good results in the application. Foreign three-dimensional design in the mold to take some practices worthy of our reference. Mold three-dimensional design in addition to the realization of integrated manufacturing, another advantage is to facilitate the interference check, can be motion interference analysis, solve a problem in the two-dimensional design.

3.digital mold technology has become the mainstream direction

In recent years, the rapid development of digital mold technology, is an effective way to solve the many problems faced in the development of automotive molds. The so-called digital mold technology is the application of computer technology or computer-aided technology (CAX) in the mold design and manufacturing process.

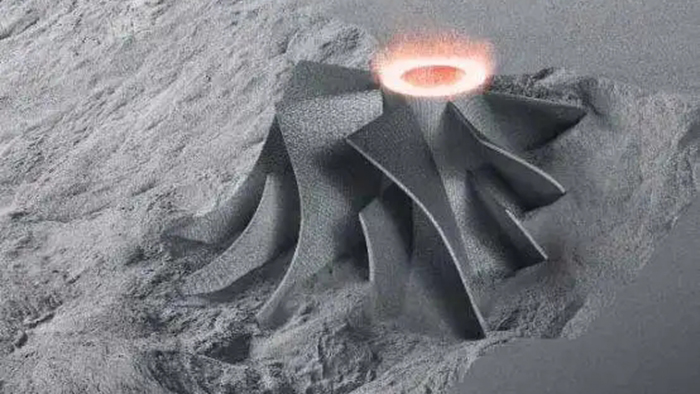

4. the rapid development of mold processing automation

Advanced processing technology and equipment is an important basis for improving productivity and ensuring product quality. In the advanced automobile mold enterprise, equipped with double table CNC machine tools, automatic tool changer (ATC), automatic processing of photoelectric control system, workpiece online measurement system, etc. is not uncommon.

CNC machining has been developed from simple type surface processing to comprehensive processing of type surface and structure surface, from low-speed processing to high-speed processing, processing automation technology development is very rapid.

5. High-strength steel stamping technology is the future development direction

High-strength steel has excellent characteristics in terms of flexural strength ratio, strain hardening characteristics, strain distribution capacity and collision energy absorption, etc., and its use in automobiles is increasing. At present, the main high-strength steels used in automotive stamping parts are baking-hardened steel (BH steel), dual-phase steel (DP steel), and phase change induced plasticity steel (TRIP steel), etc. The advanced concept model (ULSAB-AVC) launched by the International Ultra Lightweight Body Project (ULSAB) has 97% of the material as high-strength steel, and the proportion of advanced high-strength steel plates in the whole vehicle will exceed 60%, and the proportion of duplex steel will account for 74% of the steel plates used in the vehicle. Now, a large number of IF steel-based soft steel series will be replaced by high-strength steel series, and high-strength low-alloy steel will be replaced by dual-phase steel and ultra-high-strength steel plate.

At present, the application of domestic auto parts high strength steel plate is still limited to structural parts and beam-like parts, the tensile strength of the material used is more than 500MPa below, therefore, quickly grasp the high strength steel stamping technology, is China's auto mold industry is an important problem to be solved.

6. new mold products in time to launch

With the development of automobile stamping production efficiency and automation, progressive die will be more widely used in the production of automobile stamping parts. Complicated stamping parts, especially some small and medium-sized complex stamping parts that require multiple dies in sequence according to the traditional process, are more and more often shaped by progressive die.

7. mold materials and surface treatment technology will be reused

The quality and performance of mold materials is an important factor affecting the quality, life and cost of the mold. In recent years, in addition to a variety of high toughness and high wear resistance cold working mold steel, flame quenching cold working mold steel, powder metallurgy cold working mold steel launched, foreign in large and medium-sized stamping dies on the choice of cast iron materials, is a development trend worthy of attention. Ductile iron has good toughness and wear resistance, its welding performance, machinability, surface quenching properties are also better, and the cost is lower than alloy cast iron, therefore, more applications in the automotive stamping dies.

8. the scientific management and information technology is the direction of development of mold enterprises

With the progress of modern management technology, many advanced information management tools, including enterprise resource management system (ERP), customer relationship management (CRM), supply chain management (SCM), project management (PM), etc., are widely used in mold enterprises.

9. mold refinement is the inevitable trend of manufacturing

The so-called mold refinement manufacturing, is the development process and manufacturing results of the mold, specifically: the rationalization of the stamping process and mold structure design, mold processing of high precision, high reliability of the mold products and technical management of the tightness. Mold refinement manufacturing is not a single technology, but a comprehensive reflection of design, processing and management technology. The realization of mold refinement manufacturing, in addition to technical excellence, but also rely on strict management to ensure.