Vacuum casting is a practical manufacturing method popular in Australia for prototyping and small-scale production. It uses silicone moulds and vacuum pressure to create high-quality parts from polyurethane resins. This method is commonly used in industries like automotive, medical, and consumer electronics for producing prototypes and low-volume parts efficiently and cost-effectively.

Here’s a quick breakdown of its strengths and limitations:

Vacuum casting serves as a middle ground between 3D printing (ideal for very small runs and intricate designs) and injection moulding (best for high-volume production). By combining these methods, manufacturers can streamline the transition from prototype to mass production.

Quick Comparison:

| Method | Best For | Material Options | Cost | Production Speed | Surface Finish |

|---|---|---|---|---|---|

| Vacuum Casting | Prototyping, small batches | Moderate | Low | Fast | High |

| Injection Moulding | High-volume production | Extensive | High upfront cost | Very fast | Excellent |

| 3D Printing | Prototypes, intricate designs | Limited | Low for small runs | Moderate | Moderate (post-processing needed) |

For Australian manufacturers, vacuum casting is a cost-effective way to validate designs and produce limited runs without the high tooling costs of injection moulding.

Vacuum casting stands out as a budget-friendly solution for producing small to medium batches of parts, especially when compared to traditional manufacturing methods that rely on costly steel tooling. By using silicone moulds made from a master pattern, manufacturers can create a limited number of high-quality parts without the hefty expense of hard tooling.

One of the biggest perks of vacuum casting is how quickly parts can be produced. After the master pattern is prepared, crafting the silicone mould takes less than a day. From there, individual parts can be cast in just a few hours. This means Australian manufacturers can transform an idea into a physical prototype in just a matter of days - a huge plus for projects that require speed and flexibility.

Vacuum casting also shines when it comes to material options. Polyurethane resins offer a broad spectrum of properties, ranging from flexible to rigid, making this method ideal for testing different material behaviours. This versatility makes it a valuable tool across various industries.

The surface finish achieved with vacuum casting is another highlight. Silicone moulds capture intricate details, such as textures and logos, with impressive accuracy. The resulting parts often have smooth finishes that need little to no additional processing, saving time and effort.

Mastars takes vacuum casting a step further by combining it with CNC machining and 3D printing. This approach ensures consistent quality for Australian manufacturers, whether they’re working on prototypes or low-volume production runs. Industries like automotive, medical devices, and consumer electronics benefit greatly from this method, especially for components like interior parts, device housings, and enclosures.

Vacuum casting sits perfectly between 3D printing and injection moulding in terms of cost-effectiveness. For very small runs, 3D printing might be the more economical choice, while injection moulding is better suited for large-scale production due to its cost efficiencies at high volumes. But for moderate batch sizes, vacuum casting delivers production-grade parts without the need for expensive hard tooling.

Injection moulding is known for its high initial tooling costs, but it truly shines when it comes to large-scale production. While the upfront investment is significant, it becomes cost-effective as production volumes increase, delivering consistent, high-quality parts at impressive speeds.

One of the standout features of injection moulding is the sheer variety of materials available. With over 85,000 commercial plastic options listed in materials databases, manufacturers have an extensive selection to choose from. Thermoplastics dominate the scene due to their flexibility and recyclability, while thermosets make up around 15% of the materials processed annually. These materials range from flexible elastomers to high-strength engineering plastics, offering properties like durability, heat resistance, chemical stability, and electrical insulation.

The choice of material plays a critical role in determining the performance of the final product. For instance, the molecular structure of the plastic - whether it's amorphous or semi-crystalline - affects factors like dimensional stability, shrinkage rates, and resistance to chemicals. Environmental considerations are also essential, especially in Australia, where intense UV exposure can impact material longevity.

Mastars utilises injection moulding for high-volume manufacturing, ensuring precise tolerances for applications in industries such as automotive, medical, and consumer goods.

Temperature control is another crucial aspect of this process. A 10°C rise in temperature can double the rate of polymer degradation, making precise regulation essential to maintain material integrity. This level of efficiency and precision sets injection moulding apart from other manufacturing methods, such as 3D printing, which is often better suited for smaller production runs and prototypes.

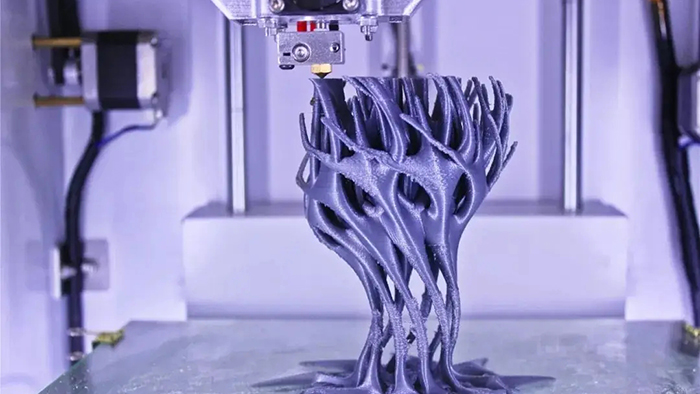

3D printing creates parts by building them layer by layer from digital files. This additive manufacturing method skips the need for moulds or tooling, making it a practical choice for low-volume production and rapid prototyping. What sets it apart is its unique cost structure compared to traditional manufacturing techniques.

Unlike other methods, 3D printing eliminates setup costs entirely, which is why it’s ideal for one-off prototypes or small production runs of fewer than 100 parts. However, there’s a catch: the per-unit cost doesn’t decrease with higher volumes. So, while it’s cost-effective for small batches, it becomes less economical when production scales to hundreds or thousands of units.

The production speed depends heavily on the complexity and size of the part. Simple designs can be printed in just a few hours, but more intricate or larger pieces may take anywhere from 12 to 24 hours. Unlike injection moulding, which offers consistent cycle times, 3D printing speeds are influenced by factors like geometry and infill density, making it less predictable for larger-scale production.

When it comes to material options, 3D printing has made strides, though it still doesn’t match the extensive range available in injection moulding. Common materials include PLA and ABS plastics for general use, while more advanced options like PEEK, carbon fibre composites, and metal powders cater to demanding applications. However, due to the layer-by-layer nature of 3D printing, the material properties often differ from those achieved through injection moulding.

Surface finish is another area where 3D printing faces challenges. Printed parts often show visible layer lines, requiring post-processing methods such as sanding, vapour smoothing, or chemical treatments to achieve a smoother appearance. The quality of the surface finish also depends on the layer height settings - finer layers deliver better results but significantly extend print times.

At Mastars, 3D printing plays a key role in rapid prototyping and small-batch production, allowing clients to test designs for form, fit, and function before committing to tooling. This service is part of their broader commitment to offering a comprehensive range of manufacturing solutions.

Beyond cost and speed, 3D printing stands out for its ability to produce designs that are nearly impossible with traditional manufacturing. Complex geometries, such as internal channels, lattice structures, and intricate organic shapes, can be created without needing assembly. This design freedom is invaluable for producing custom medical devices, aerospace components, and architectural models where intricate details are critical.

Let’s break down the key strengths and limitations of each manufacturing method to help you decide which one fits your project needs. Every approach has its own perks and trade-offs, making it ideal for certain applications. By understanding these differences, you can make informed choices that suit your specific goals.

Vacuum casting stands out for prototyping and small-batch production. It delivers high-quality, production-grade finishes, though it’s somewhat limited in terms of material options and the durability of its moulds.

Injection moulding shines when it comes to large-scale production. It supports a wide variety of industrial plastics, ensuring precision and durability. While the upfront tooling costs can be steep, the method becomes highly economical as production volumes increase.

3D printing is unmatched for its design flexibility and lack of setup costs. It allows for the creation of intricate designs, such as internal channels and lattice structures, that are difficult to achieve with traditional methods. However, its layer-by-layer approach can sometimes result in visible surface textures, and the mechanical properties of the parts may differ from those made through moulding.

Combining these methods can simplify the journey from prototype to full-scale production. At Mastars, the integration of 3D printing, vacuum casting, and injection moulding makes this transition smoother. A typical workflow might begin with 3D printing for early prototypes, move to vacuum casting for market testing and small production runs, and finally shift to injection moulding for mass production. This approach helps balance cost and lead times across the entire product lifecycle.

Whether you’re focusing on prototype validation, testing the market, or mass production, the key is to weigh your options carefully - considering factors like cost, timelines, and material needs.

Vacuum casting acts as a practical bridge between 3D printing and injection moulding, offering production-grade parts with impressive speed. It’s particularly well-suited for prototyping and small-batch production runs. That said, it becomes less practical for larger-scale production, especially when volumes exceed 25 parts per mould, and its limited material options may not suit every application.

For Australian manufacturers, vacuum casting provides a cost-effective and efficient way to transition from prototypes to market-ready products, avoiding the steep upfront tooling costs of other methods. This makes it a smart choice for testing market demand or creating limited-edition products.

Mastars caters specifically to the Australian market with vacuum casting services that deliver ±0.3% accuracy and produce up to 10 parts in just 15 working days. Their capabilities include handling dimensions up to 1,900 × 900 × 750 mm and customising materials for hardness, colour, and other specifications to meet local requirements. With expertise across various manufacturing techniques, Mastars ensures a smooth progression from prototype to full-scale production.

Knowing when to leverage vacuum casting can make a real difference in keeping project timelines and budgets on track. For Australian businesses looking to streamline their product development, vacuum casting offers a reliable way to achieve production-quality results without the limitations of traditional manufacturing methods.

Vacuum casting is often seen as a more eco-friendly option for small-scale production because it uses materials efficiently and generates minimal waste. Unlike injection moulding, which demands substantial resources and energy for large-scale manufacturing, vacuum casting works well for low-volume production, cutting down on material use and reducing its environmental footprint.

While 3D printing can lean towards sustainability when using bio-based or recycled materials, it generally consumes more energy per part and may create waste depending on the method used. In contrast, vacuum casting often stands out as a greener choice for low-volume manufacturing, especially when precision and material efficiency are top priorities.

In Australia, vacuum casting plays a key role in producing prototypes, intricate models, and small-batch production parts. Industries like aerospace, automotive, product design, and art lean on this technique because it delivers detailed, durable components with a finish that closely mimics injection-moulded parts.

This process stands out in these fields thanks to its ability to handle small production runs affordably, accommodate complex shapes, and offer a fast turnaround time. These strengths make vacuum casting a go-to option for projects that demand precision, visual appeal, and functional prototypes.

To choose the most cost-effective production method, manufacturers need to weigh factors like production volume, design complexity, and material requirements. Vacuum casting and 3D printing are excellent choices for small batches or prototypes because they come with lower upfront costs. Among these, 3D printing stands out as a budget-friendly option for producing intricate designs or very low volumes.

When it comes to larger production runs, injection moulding takes the lead in cost efficiency. As quantities increase, the per-unit cost drops significantly, making it an ideal choice for volumes of 10,000 units or more. Carefully assessing your production needs and forecasted quantities is key to selecting the right method.

At Mastars, we offer expertise in all three methods - vacuum casting, 3D printing, and injection moulding. By providing tailored solutions, we deliver high-quality and cost-efficient results across various industries, including automotive and medical devices.