Looking to speed up your product development? Here's what you need to know: 3D printing is transforming prototyping. It’s faster, more cost-effective for small runs, and ideal for testing complex designs. But traditional methods like CNC machining and injection moulding still lead when precision, surface finish, or production-grade materials are required.

Which is better? Use 3D printing for early-stage iterations or testing intricate designs. Switch to conventional methods for final prototypes requiring durability or regulatory compliance. Combining both approaches can save time and money while meeting project demands.

3D printing has reshaped the way industrial design prototypes are created, offering unmatched flexibility and quick turnaround times. By constructing objects layer by layer from digital files, it eliminates the need for complicated tooling. Let’s dive into how 3D printing stands out in terms of speed, cost, applications, and material options.

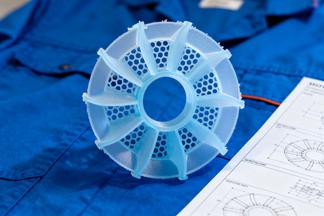

One of the standout benefits of 3D printing is how quickly it can produce prototypes. Designs with intricate geometries that would normally take multiple machining steps can often be completed in a single print session. For simpler prototypes, the process can take just a few hours, while more complex designs might need 24–48 hours.

This rapid pace means designers can print prototypes overnight and review them the next day. It’s easy to make adjustments - just update the digital file and start printing again. There’s no downtime waiting for tooling changes or machine setups, allowing for multiple iterations in just a few days.

When it comes to cost, 3D printing offers a unique advantage, especially for small-scale or one-off prototypes. Unlike traditional methods, there’s no need for expensive tooling or fixtures, which keeps initial costs low.

Material costs depend on the type of material used, but additive manufacturing is inherently efficient, generating far less waste compared to subtractive methods. Labour costs are also reduced because a single operator can oversee several printers at once. This combination of low setup costs, material efficiency, and minimal labour makes 3D printing a practical choice for many prototyping needs.

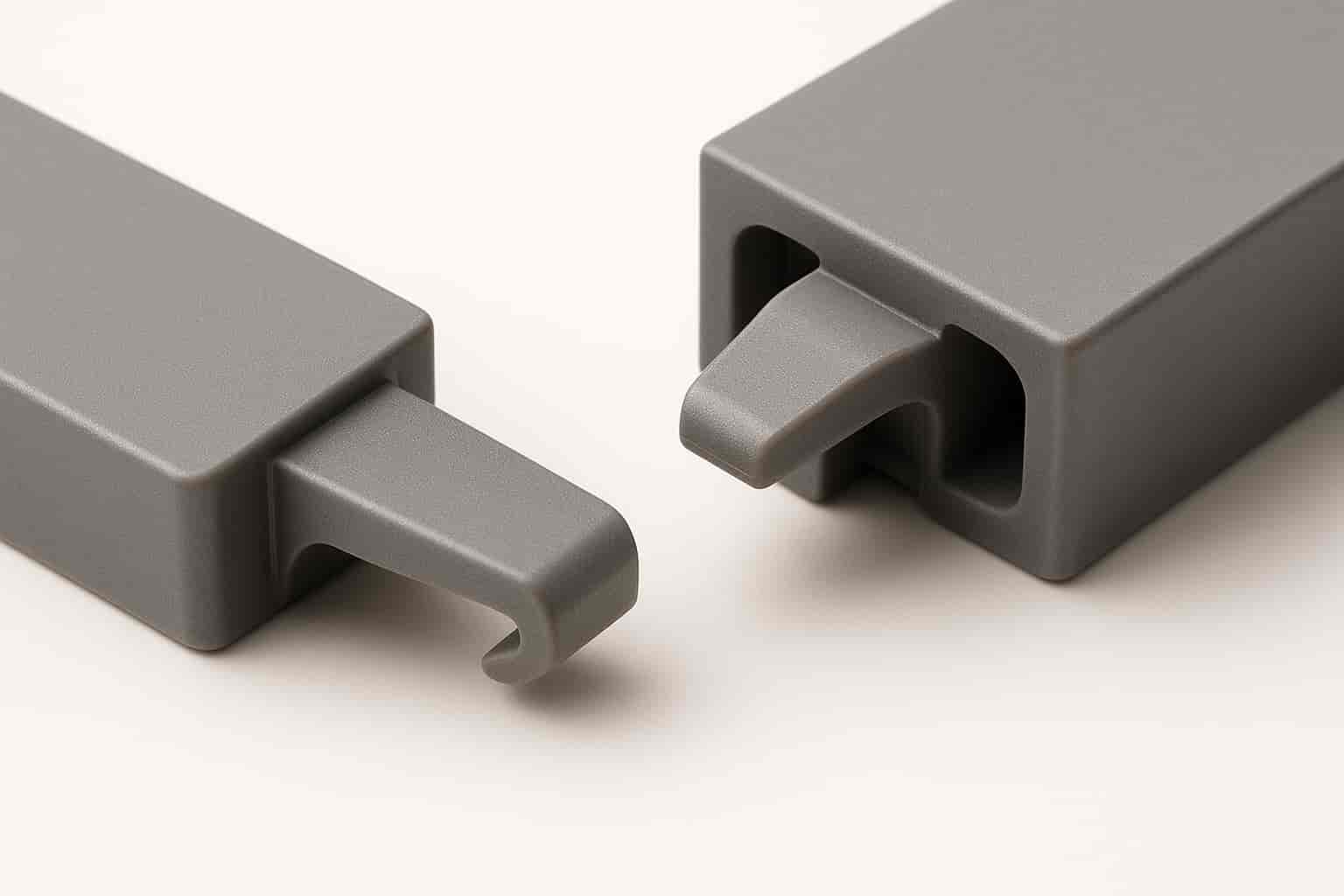

3D printing shines in specific scenarios, particularly when prototypes require complex internal geometries, lattice structures, or consolidated assemblies. It’s ideal for testing mechanical components, evaluating fit and finish, and validating designs before committing to full-scale production.

This technology is especially useful for ergonomic testing and user interface development, where hands-on interaction with a prototype is crucial. Industries like medical devices, automotive interiors, and consumer electronics benefit greatly from 3D printing’s ability to quickly produce functional models. However, for components that need to endure high stress or have a polished surface finish, additional post-processing or alternative methods might be required.

Choosing the right material is essential for effective prototyping, and 3D printing offers a wide variety of options to suit different needs. Engineering plastics like ABS, PETG, and nylon are commonly used for their reliable mechanical properties in functional testing. For more demanding applications, materials such as glass-filled nylon or carbon fibre composites provide added strength and stiffness.

Metal 3D printing allows for prototyping with materials like aluminium, stainless steel, and titanium alloys. These are perfect for industries like aerospace, medical devices, and high-performance automotive components where production-grade material properties are critical, though they come at a higher cost.

For projects requiring flexibility, materials like TPU are ideal for creating gaskets, seals, or soft-touch components. Additionally, multi-material printing can combine different properties within a single prototype - something traditional methods struggle to achieve.

Companies like Mastars integrate advanced 3D printing with conventional prototyping techniques, ensuring manufacturers can choose the best approach for their specific needs while maintaining high quality and timely delivery.

Traditional prototyping methods, such as CNC machining and injection moulding, have been staples in industrial design for decades. While these techniques are reliable and offer a wide range of material options, they come with limitations that set them apart from the flexibility of 3D printing.

One of the biggest challenges of conventional prototyping is the time it takes to deliver a finished product. The process often stretches over weeks or even months due to the extensive preparation involved. For instance, creating moulds for injection moulding alone can take several weeks, and production only begins once the tooling is complete. Adding to this are the preliminary steps like drafting designs, submitting purchase orders, and dealing with shipping delays.

Markforged noted: "Using traditional manufacturing methods, prototypes require new tooling, and/or additional processes like drafting drawings, submitting POs, and dealing with shipment times. Without in-house 3D printing, procuring each prototype can take weeks to months."

These labour-intensive processes often cause bottlenecks, slowing down the entire development cycle. Compared to the rapid turnaround times of 3D printing, traditional methods can feel painstakingly slow.

Cost is another area where traditional methods differ significantly. These techniques often involve high upfront expenses, particularly for tooling and setup. For example, injection moulding requires custom moulds that can cost thousands of dollars, making it practical only for larger production runs. Subtractive manufacturing methods, like CNC machining, also generate material waste, which can be especially expensive when working with high-cost materials like aerospace-grade aluminium or medical-grade stainless steel.

On top of that, operating these traditional machines requires skilled labour, further driving up costs. Machinists and technicians are needed to handle complex equipment and ensure quality control throughout the process, adding to the overall expense.

Despite their drawbacks, conventional prototyping methods excel in specific applications. They are indispensable when high precision, exceptional surface finishes, or production-grade material properties are needed. CNC machining, for instance, can achieve tolerances as tight as ±0.01mm, making it ideal for precision mechanical components that demand exact fits.

These methods are particularly useful for prototypes that will undergo rigorous testing in demanding environments. Automotive suspension parts, aerospace structural components, and heavy machinery elements often rely on traditionally manufactured prototypes to meet stringent performance criteria.

Traditional techniques are also advantageous for prototypes requiring the integration of multiple materials. Unlike 3D printing, which can struggle with combining materials, conventional methods easily incorporate features like metal inserts or gaskets during fabrication.

One of the strongest advantages of traditional prototyping lies in its material versatility. CNC machining works with nearly any machinable material, from hardened steels and titanium alloys to ceramic composites. This flexibility allows manufacturers to use materials that might not be compatible with 3D printing.

Injection moulding further enhances this by enabling prototypes to be made from the same materials intended for final production. These include glass-filled nylons, flame-retardant plastics, and medical-grade polymers that meet specific certifications. Such material authenticity is essential for prototypes undergoing regulatory testing or certification.

Sheet metal fabrication also expands the range of prototyping options, allowing the use of standard industrial materials like galvanised steel, aluminium alloys, and various grades of stainless steel. These materials have well-documented performance characteristics, making them a reliable choice for many applications.

For those seeking a balance between traditional and modern methods, companies like Mastars offer hybrid solutions. They combine the precision and reliability of conventional techniques with newer approaches, ensuring manufacturers can access the best of both worlds. This blend of material options and process reliability highlights how traditional methods remain a vital part of the prototyping landscape.

When comparing 3D printing with conventional manufacturing methods, each approach brings its own strengths and limitations to the table. These differences can significantly impact design validation and production costs, depending on the project's requirements.

3D printing stands out for its ability to create intricate geometries quickly and with great design flexibility. It offers low setup costs, making it easier to move from concept to prototype in a short time. This speed is especially useful during early design stages when testing multiple iterations is key to refining ideas.

That said, 3D printing does have its drawbacks.Material options and surface finish quality remain challenges. While the range of printable materials is growing, it still doesn't match the variety offered by traditional methods. Additionally, many 3D-printed parts require post-processing to achieve high-quality finishes, which can add time and expense to the process.

On the other hand, conventional methods excel where 3D printing falls short. Techniques like CNC machining and injection moulding deliver high precision and material authenticity. For example, CNC machining achieves tolerances as tight as ±0.01mm, and injection moulding allows prototypes to be made from production-grade materials. These methods are essential for prototypes that need to undergo rigorous testing or meet exact regulatory standards before moving to full production.

The trade-off? Traditional methods often come with higher upfront costs and longer timelines. Tooling can take weeks to prepare and cost thousands of dollars, making these methods less practical for early-stage development or low-volume production.

| Factor | 3D Printing | Conventional Methods |

|---|---|---|

| Speed | Hours to days | Weeks to months |

| Initial Cost | Low (AUD $50–500 per part) | High (AUD $1,000–10,000+) |

| Material Range | Limited but expanding | Extensive |

| Precision | ±0.1–0.3mm typical | ±0.01–0.05mm achievable |

| Design Complexity | Excellent for intricate designs | Limited by manufacturing constraints |

| Surface Finish | Often requires post-processing | High-quality out of process |

| Volume Economics | Best for low volumes | Ideal for higher volumes |

| Industry Suitability | Consumer electronics, medical devices, concept models | Automotive, aerospace, heavy machinery |

The industry applications for these methods vary widely. Automotive and aerospace sectors often lean on conventional techniques because of their ability to produce parts that can withstand extreme conditions and meet strict regulatory demands. In contrast, industries like consumer electronics and medical devices benefit from 3D printing's speed and flexibility during the concept phase.

Ultimately, the choice between these methods hinges on the purpose of the prototype. Early-stage design validation often calls for 3D printing due to its quick turnaround and adaptability. However, when prototypes need to replicate final production materials or meet stringent testing requirements, conventional methods take the lead. Companies like Mastars address this by offering both options, allowing manufacturers to choose the best approach for each stage of development.

Cost considerations also play a significant role. While 3D printing keeps initial costs low, traditional methods can become more economical for larger runs where tooling can be reused. Typically, the break-even point occurs at around 10–50 parts.

Finally, geographic factors influence the choice of method. In Australia, industries like mining, agriculture, and medical technology often demand the robust material properties provided by conventional methods. At the same time, the country’s growing startup ecosystem is increasingly turning to 3D printing for rapid prototyping and market validation, demonstrating the complementary strengths of these technologies.

Deciding between 3D printing and conventional prototyping comes down to understanding your project's specific needs, timelines, and budget.

For early-stage development, 3D printing offers speed and cost efficiency, making it ideal for quick iterations. This capability is especially valuable when you're racing against tight deadlines to bring a product to market.

On the other hand, conventional prototyping shines in scenarios where precision, material authenticity, and compliance are non-negotiable. Industries like automotive, aerospace, and medical devices often rely on traditional methods for their ability to meet strict tolerances and use production-grade materials, even if it means higher upfront costs.

By combining both methods, you can create a more efficient prototyping process. Start with 3D printing for concept validation and design tweaks, then shift to conventional techniques for final prototypes that need rigorous testing or meet regulatory standards. This hybrid approach allows you to capitalise on the strengths of both methods while minimising their limitations.

For Australian manufacturers, working with an integrated service provider like Mastars can simplify this process. Offering services such as 3D printing, CNC machining, injection moulding, and vacuum casting under one roof, they help streamline supplier management while ensuring consistent quality throughout your prototyping journey.

3D printing stands out as a game-changer when compared to traditional manufacturing methods like CNC machining and injection moulding, especially in terms of speed and cost for prototyping. With 3D printing, designs can often transition from concept to physical model in just a matter of hours or days. This is a stark contrast to the weeks typically needed for tooling and machining, offering a much faster turnaround.

When it comes to cost, 3D printing is particularly well-suited for low-volume production and intricate designs. Unlike injection moulding or CNC machining, it skips the need for costly moulds or tooling. This makes it an excellent option for early-stage design testing and producing small batches. Its adaptability enables designers to experiment, test, and refine ideas without breaking the bank, cementing 3D printing as an essential tool in industrial design prototyping.

3D printing shines when it comes to producing intricate and detailed prototypes in a short amount of time and without breaking the bank. Its ability to handle low-volume production and support rapid design tweaks makes it a go-to option for projects with tight deadlines or complex shapes that traditional methods might struggle with.

That said, methods like CNC machining or injection moulding often take the lead for high-volume production, precision-focused tasks, or when specific materials are required. These approaches are better equipped to deliver consistent results and cost efficiencies at scale, making them the preferred choice for final production runs or highly specialised applications.

3D printing provides access to a broad variety of materials, including plastics like ABS, PLA, PETG, and nylon, as well as metals and composites such as carbon fibre-reinforced filaments. Each material comes with its own set of characteristics, making it well-suited for different applications across various sectors.

Take plastics, for instance. Their affordability and adaptability make them a go-to choice for rapid prototyping and creating consumer products. On the other hand, metals and advanced composites shine in fields like automotive, aerospace, and medical devices, where strength, durability, and high performance are essential. The material you choose significantly impacts the final product's qualities, such as its strength, flexibility, and heat resistance. This allows industries to develop solutions tailored to their specific needs.