Should you invest in Automatic Tool Changers (ATCs) or stick with manual systems? Here's the short answer: ATCs save time and improve efficiency in high-volume machining but come with a higher upfront cost. Manual systems are cheaper to set up but slower and more labour-intensive.

| Feature | Automatic Tool Changers (ATCs) | Manual Systems |

|---|---|---|

| Upfront Cost | High | Low |

| Change Time | 1-5 seconds | Up to 15 minutes |

| Best For | High-volume production | Prototyping, small runs |

| Flexibility | Handles multiple tools | On-the-spot changes |

| Labour Costs | Lower | Higher |

| Maintenance | Regular upkeep needed | Minimal |

The right choice depends on your production needs, budget, and long-term goals.

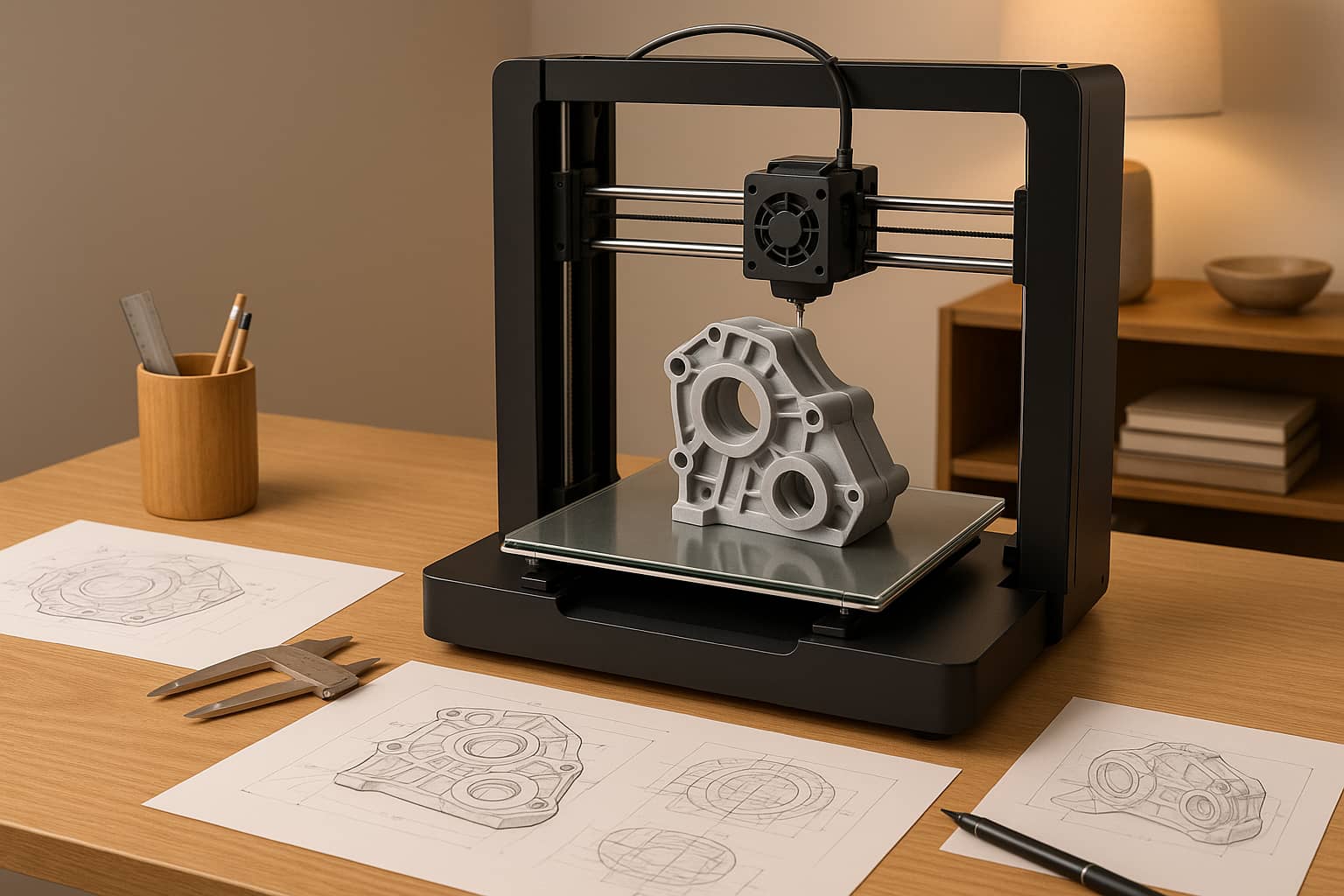

Automatic tool changers have revolutionised CNC machining, changing the way Australian manufacturers handle their production processes. These systems are built directly into CNC machines, allowing tools to be swapped automatically during machining - eliminating the need for manual intervention. Below, we’ll explore the costs involved and the operational advantages they bring.

The cost of installing an ATC system can vary based on its complexity and capacity. For manufacturers with steady production needs, simpler systems with fewer tools may suffice. However, advanced ATC setups are ideal for operations requiring a broader range of tools. Key factors influencing the overall cost include the hardware itself, software integration, training for operators, and maintaining a sufficient inventory of tools.

One of the standout benefits of ATCs is how they drastically cut downtime, with tool changes taking as little as 1 to 5 seconds. This efficiency reduces labour costs tied to manual tool changes and supports continuous production. To keep the system running smoothly, regular maintenance - like cleaning and lubricating the tool magazine and grippers - is essential.

ATCs can slash manual tool-change times by up to 80%, reducing changeovers from 15 minutes to less than 3 minutes. This improvement can boost machine utilisation by at least 30%. Beyond time savings, ATCs allow for greater production flexibility, handling a variety of tool configurations and enabling quick process adjustments. Their standardised operations also minimise human error, leading to better part quality. These efficiency improvements not only streamline production but also result in tangible cost savings, boosting the overall return on investment.

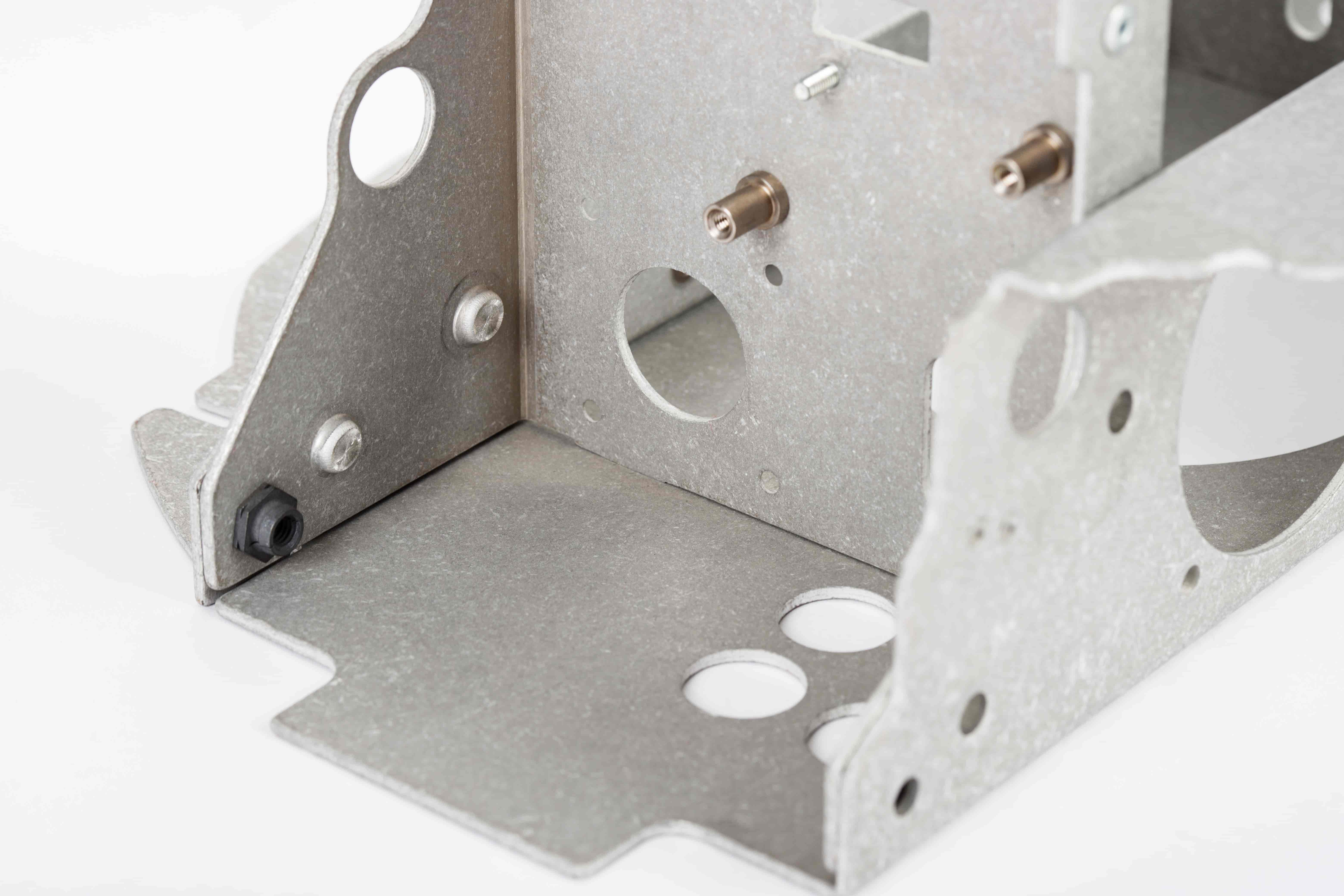

Unlike Automatic Tool Changers (ATCs), manual systems require operators to physically swap tools themselves. While this approach may seem outdated, it still suits certain Australian manufacturing needs. Let’s take a closer look at their costs, operational requirements, and efficiency considerations.

One of the biggest advantages of manual systems is their low upfront cost. With no need for complex machinery, software integration, or extensive training, these systems are an attractive option for smaller workshops, hobbyists, and businesses focused on prototyping. Their straightforward design keeps installation expenses minimal.

However, the savings on installation come with higher ongoing expenses. Every tool change requires a skilled operator, which means more downtime, higher labour costs, and potential inconsistencies in production. Over time, these factors can add up, especially in operations with frequent tool changes.

Manual systems shine in situations where flexibility is key. For prototyping or small-scale production, they allow for quick, on-the-spot adjustments. But this adaptability comes at a cost - manual systems simply can’t match the speed or consistency of ATCs in high-volume production environments. While they save on initial expenses, they often result in slower throughput and less predictable results.

When it comes to choosing between Automatic Tool Changers (ATCs) and manual systems, the decision often comes down to balancing upfront costs with long-term efficiency. Each system has its own strengths, and the choice largely depends on the nature of the production environment.

ATCs are ideal for high-volume operations. They can run continuously without manual intervention, which boosts consistency and reduces variability in production. However, these advantages come with some trade-offs. The systems are more complex, requiring regular maintenance, software updates, and occasional specialised technical support.

Manual tool change systems, on the other hand, shine in smaller-scale or custom manufacturing setups. They offer greater flexibility for prototypes or one-off projects and come with a lower initial investment. But this affordability has its drawbacks - manual systems tend to have slower throughput and higher labour costs due to the hands-on nature of their operation.

While ATCs demand regular calibration and careful upkeep to maintain performance, manual systems require consistent attention to ensure safety and reliability.

Ultimately, the decision between ATCs and manual systems depends on factors like production volume, available budget, and specific operational requirements. By evaluating these elements, manufacturers can align their tool-changing approach with their broader production goals.

Choosing between automatic tool changers (ATCs) and manual systems ultimately comes down to weighing the cost against the needs of your operations. ATCs are ideal for high-volume production where frequent tool changes are essential in multi-stage machining. On the other hand, manual systems are better suited for smaller-scale, flexible projects. The right choice hinges on factors like production volume, budget, and future growth plans.

Mastars adopt a mix of both - leveraging ATCs for large-scale tasks while relying on manual systems for custom or rapid prototyping work.

Take a close look at your production workflow to decide if the efficiency gains from ATCs are worth the investment.

Investing in automatic tool changers (ATCs) offers long-term advantages that can more than justify the upfront expense. By cutting down on downtime and reducing the need for manual adjustments, ATCs boost machine efficiency and overall productivity. This translates into reduced operational costs over time.

Beyond efficiency, ATCs also improve precision and ensure consistent results. They help minimise tool wear and decrease the need for rework, which lowers labour and material costs while keeping the production process running smoothly. For industries focused on streamlining operations and managing costs effectively, ATCs are a smart choice.

Automatic tool changers (ATCs) play a key role in boosting production efficiency by allowing quick and effortless tool changes. This means less machine downtime and shorter setup times, helping manufacturers keep operations running smoothly - especially when demand is high.

Another advantage of ATCs is their ability to enhance accuracy and uniformity. By reducing the likelihood of human error, they help deliver consistent, high-quality results. This is particularly beneficial for industries that deal with high-volume production or intricate manufacturing tasks. While ATCs may require an upfront investment, the time and efficiency savings they provide can make them a worthwhile addition to any production setup.

When choosing between an automatic tool changer (ATC) and a manual system, it's essential to weigh factors like cost, efficiency, and your production demands. ATCs shine in high-volume manufacturing environments. They boost efficiency, cut downtime, and lower labour costs - making them a smart choice when precision, consistency, or frequent tool changes are part of the equation.

On the other hand, manual systems come with a lower upfront cost but can slow things down in more demanding workflows or larger production runs. That said, they can be a better fit for low-volume production, prototyping, or operations with simpler tooling requirements. It’s also important to consider how complex your tooling is, how often tools need changing, and whether your team is trained to handle an ATC.

The best option will depend on your manufacturing goals, budget, and how your processes are set up. If you're looking for dependable and efficient solutions, Mastars provides integrated manufacturing services, including tooling and prototyping, to help streamline operations and meet your production needs.