Switching from paper to digital documentation can transform CNC machining operations in Australia. Here's why it matters:

For Australian manufacturers, adopting digital systems can improve productivity, quality, and compliance while reducing costs tied to inefficiencies. The shift requires careful planning, including meeting local data privacy laws and choosing scalable, user-friendly solutions. But the benefits far outweigh the initial investment, ensuring businesses stay competitive in a rapidly evolving industry.

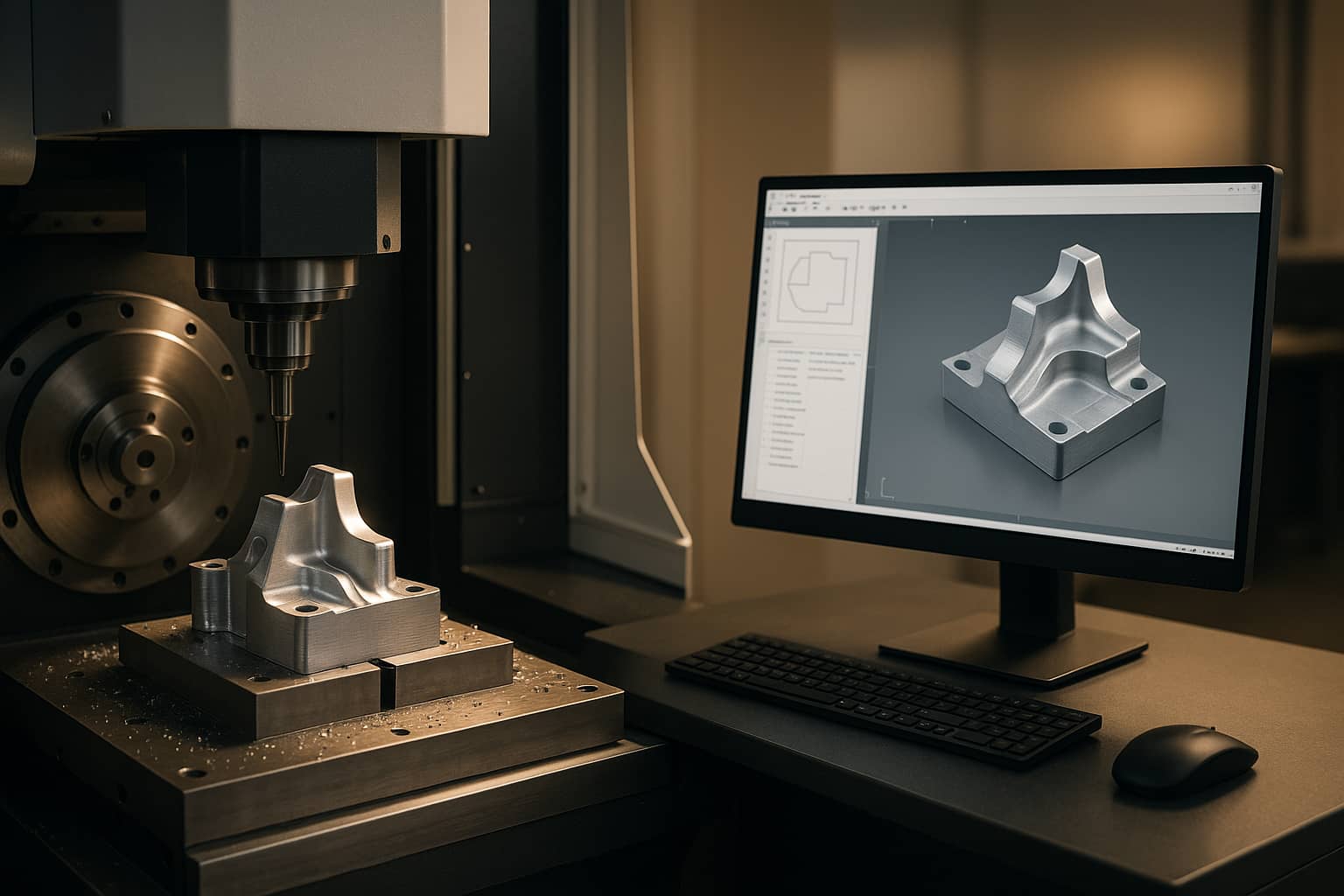

Digital documentation systems have reshaped CNC machining by addressing the inefficiencies of paper-based workflows. These platforms do much more than store files - they introduce advanced tools that solve common challenges and streamline operations. Understanding their key features can guide manufacturers in navigating their digital shift effectively.

One major advantage of digital systems is their ability to provide real-time access to critical information, eliminating delays and errors tied to paper processes. These systems centralise essential documents like setup sheets, G-code files, work instructions, and maintenance logs, making them instantly accessible from anywhere on the shop floor.

Operators can quickly retrieve the latest specifications directly at their workstations, allowing for immediate adjustments when needed. For quality inspectors, sharing measurement data with engineering teams becomes seamless, enabling quicker resolutions when tolerances are in question. Maintenance technicians, on the other hand, can consult complete service histories and troubleshooting guides straight from their mobile devices, cutting down on machine downtime.

Another standout benefit is the ability to update information instantly. Design engineers can make changes that are immediately visible to all relevant personnel, preventing errors caused by outdated documents. This ensures everyone is working with the most up-to-date information, reducing the risk of rework or scrapped parts.

Managing document versions is another area where digital systems excel. Unlike paper systems, where multiple versions of the same document can circulate and create confusion, digital platforms maintain a single source of truth. Only the most current, approved version of a document is accessible, ensuring consistency across the board.

These systems also track every modification, creating detailed audit trails that show who made changes, when they were made, and what was altered. This transparency ensures operators always have access to the latest instructions, minimising the risk of machining errors due to outdated specifications.

Automated notifications further enhance this feature by alerting relevant team members whenever a document is updated. Approval workflows can also be enforced, ensuring that unapproved changes never reach the production floor. This controlled approach not only protects document integrity but also supports continuous improvement efforts.

The true power of digital documentation systems becomes evident when they integrate seamlessly with existing manufacturing systems. Modern platforms connect with tools like Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and Quality Management Systems (QMS), creating a unified workflow that spans the entire production process.

This integration eliminates manual data entry errors by automatically pulling relevant drawings, specifications, and instructions from ERP systems as soon as a work order is created. Operators receive this information in a clear, organised format, ready for immediate use.

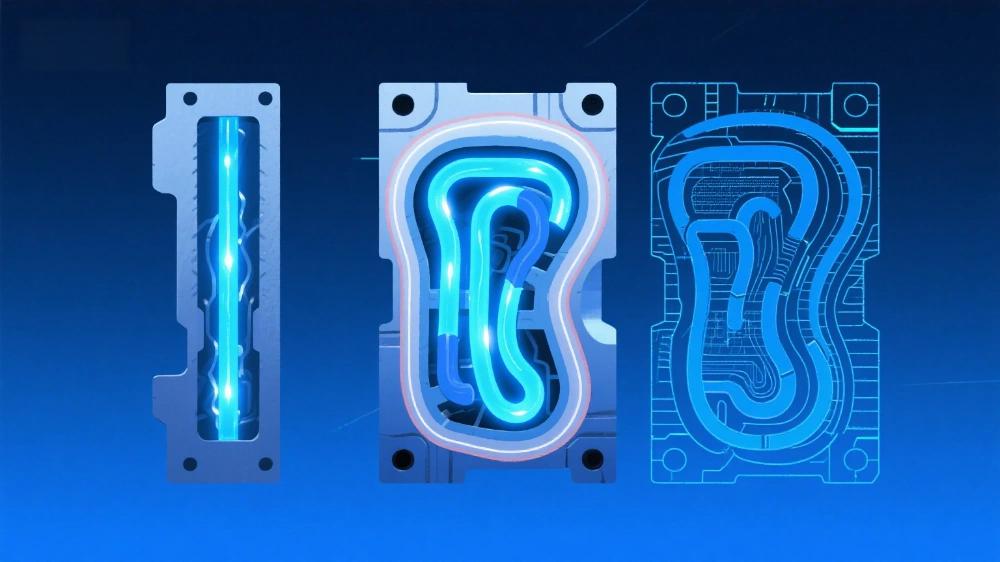

Machine connectivity adds another layer of efficiency. Some systems can communicate directly with CNC controllers, automatically uploading the correct G-code programs and downloading production data. This ensures that the right program is always loaded while capturing real-time performance metrics for analysis and improvement.

Integration also supports predictive maintenance by linking machine performance data with maintenance records. Tasks can be scheduled based on actual machine usage instead of fixed intervals, maximising equipment availability and reducing unexpected breakdowns.

Switching from paper-based systems to digital documentation brings measurable improvements to CNC manufacturing processes. These advantages go beyond mere convenience, offering real savings, better quality outcomes, and improved efficiency. They also complement the streamlined workflows discussed earlier.

Digital documentation plays a key role in reducing production errors and minimising downtime. By replacing outdated and often confusing paper methods, digital systems ensure operators always have access to the most accurate and current information. Misreading handwritten notes or working from outdated drawings can lead to defective parts, rework, and delays - issues that digital systems help to eliminate.

With precise digital instructions and visual aids, setup accuracy improves significantly. Tasks that once required highly experienced machinists can now be handled correctly by less experienced operators. This reduces reliance on senior staff and creates more flexibility in scheduling. Maintenance teams also benefit, as they can quickly access complete machine histories, which shortens repair times and reduces mean time to repair (MTTR).

Training new operators becomes more efficient too. Interactive modules, step-by-step guides, and searchable knowledge bases help new hires get up to speed faster, easing the burden on experienced team members.

Digital systems also simplify compliance with increasingly strict regulatory requirements, particularly in industries like aerospace, medical devices, and automotive. These systems provide the tracking and reporting tools necessary to meet standards such as ISO 9001, AS9100, and ISO 13485.

Automated audit trails make compliance straightforward by documenting every action, from creating and revising documents to their approval and distribution. They record who accessed critical information and when changes were made, ensuring all data is readily available during audits. This not only demonstrates compliance but also saves significant time during audit preparation.

Digital signatures and electronic approvals add another layer of security, offering legally binding documentation while eliminating risks like forged or missing signatures. Features like time stamps and user authentication create a secure chain of custody, meeting even the most rigorous regulatory demands. Role-based access controls further ensure that only authorised personnel can modify sensitive documents.

By automatically linking production records to specific document versions, traceability is enhanced. If a quality issue arises, manufacturers can quickly trace it back to the procedures or personnel involved, enabling faster root cause analysis and corrective actions.

Finally, document retention and archival are far easier with digital systems. Instead of dedicating physical space to years’ worth of paper records, manufacturers can store decades of information in compact, searchable digital archives that are instantly accessible.

Digital documentation revolutionises how teams share knowledge and communicate within CNC operations. Cross-shift communication improves when operators can leave detailed digital notes about machine performance, setup challenges, or quality concerns for the next shift. Unlike paper-based systems, this ensures valuable insights are preserved and shared.

Remote collaboration is another major advantage. Engineers can provide real-time support to shop floor operators without needing to be on-site. For instance, if a complex setup issue arises, operators can share photos, measurements, and observations through the digital system, enabling engineers to offer immediate guidance. This feature has proven especially useful during times when travel restrictions make on-site support difficult.

Digital systems also bridge language barriers, ensuring that diverse teams can access and understand critical information. As experienced machinists develop new techniques or solve recurring issues, these systems provide structured ways to document and share their expertise. Over time, searchable knowledge bases grow as teams contribute insights, safeguarding institutional knowledge even as staff members come and go.

Analytics generated by digital systems further enhance collaboration by identifying best practices and encouraging team-wide improvements. Together, these features elevate overall CNC performance and foster a culture of continuous improvement.

Switching to digital documentation systems can be a game-changer for Australian manufacturers, but it requires careful planning to address specific challenges. From meeting regulatory standards to ensuring your workforce adapts to the change, every step needs thoughtful execution.

In Australia, strict data protection laws like the Privacy Act 1988 and the Notifiable Data Breaches scheme make safeguarding personal and business information a top priority. For manufacturers, especially those handling sensitive client data or proprietary designs in CNC operations, compliance is non-negotiable.

Start with a thorough data audit. Categorise records - such as employee details, client specifications, machine performance metrics, and quality control data - by sensitivity level. Implement security measures tailored to each category, including end-to-end encryption and systems that ensure Australian data residency. This is especially vital for companies working with government contracts or defence projects, where data sovereignty is a must.

Strengthen security by using multi-factor authentication and role-based access controls to limit who can access critical documents. Regular security audits and penetration testing can help identify and address vulnerabilities. Partnering with local cybersecurity firms can provide monitoring services tailored to Australian regulations.

Document your security protocols to show regulators that you’re proactive about compliance. Also, create a clear incident response plan that outlines how your team will handle data breaches, from reporting the issue to containing it. By prioritising security, you’ll not only meet legal requirements but also build trust with clients and stakeholders.

To ensure your digital systems work seamlessly in Australian settings, they need to reflect local standards. Configure them to use metric units like millimetres, metres, and kilograms, display temperatures in Celsius, and handle transactions in Australian dollars ($AUD). Automate time zone adjustments for AEST/AEDT to avoid scheduling errors.

Workforce diversity is another consideration. Australia’s manufacturing sector employs people with varying levels of English proficiency and digital skills. Choose systems with user-friendly interfaces that minimise training time and reduce the chance of errors. This inclusivity can significantly boost the adoption rate among employees.

Local support is another key factor. Choose vendors that offer 24/7 Australian-based technical assistance to minimise downtime, especially during night shifts or weekends when international support might be unavailable. Once your system is tailored to Australian standards, you’ll be better equipped to maintain smooth operations.

The right system should integrate effortlessly with your existing digital workflow, enhancing CNC machining performance. Start by assessing your current infrastructure, including ERP, CAD, and machine controllers, to identify integration needs.

Scalability is crucial. Opt for systems that can grow with your business, allowing you to add users, machines, or facilities without overhauling the platform. Modular pricing models are ideal, as they let you pay for features as you need them, avoiding unnecessary costs.

Vendors with an established presence in Australia can offer faster response times and a better understanding of local requirements. Look for client references from Australian businesses to gauge their reliability. Additionally, ensure the system supports integration with your current CAD software and legacy systems. APIs can be incredibly useful for customising integrations with specialised equipment.

When evaluating costs, go beyond the initial licensing fees. Include expenses like training, ongoing support, hardware upgrades, and potential productivity dips during implementation. Many vendors offer pilot programs to test the system with a small team before committing fully - this can help identify any issues early on.

Comprehensive training is non-negotiable. The best system won’t deliver results if your team doesn’t know how to use it. Look for vendors that provide on-site training, online resources, and continuous support to ensure your team gets the most out of the system.

Finally, choose a vendor with a strong development roadmap. Technology evolves quickly, so it’s essential to work with a partner committed to regular updates, new features, and incorporating user feedback. A forward-thinking vendor is an investment in your business’s future.

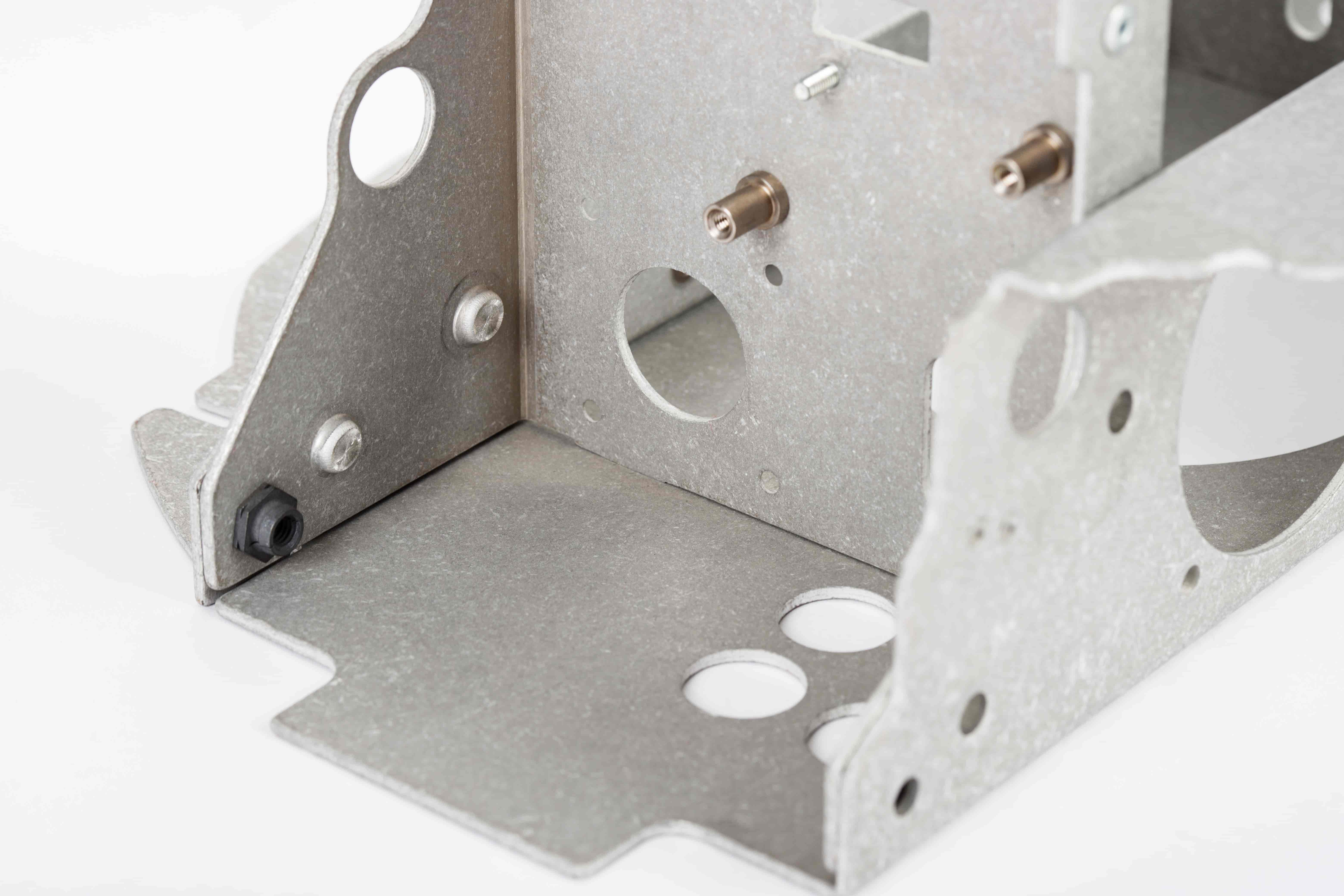

Mastars combines the craftsmanship of traditional machining with the efficiency of cutting-edge digital workflows. As a comprehensive OEM manufacturing and product development company, Mastars offers a one-stop shop for precision components across a wide range of industries. Their expertise spans an impressive array of manufacturing capabilities.

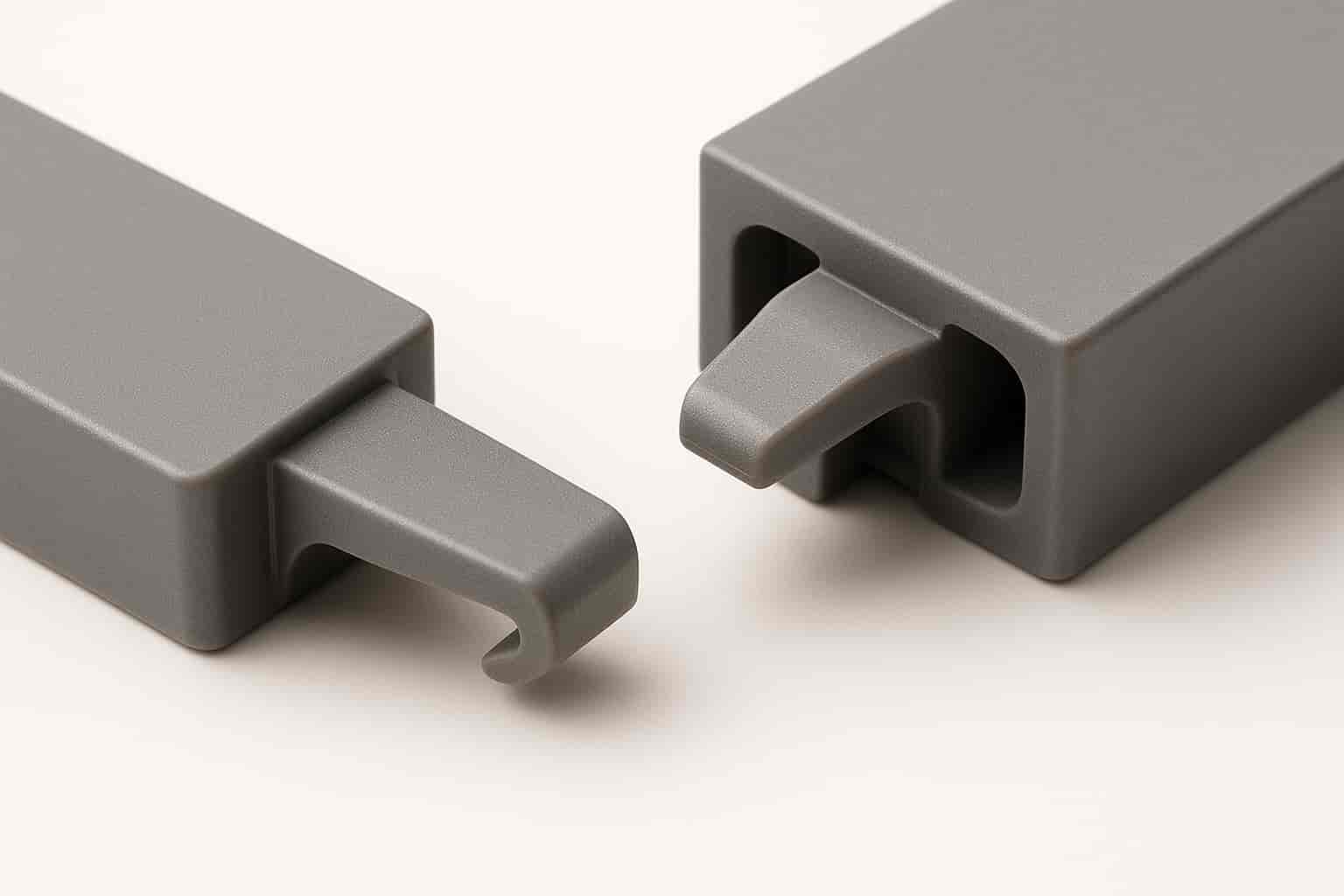

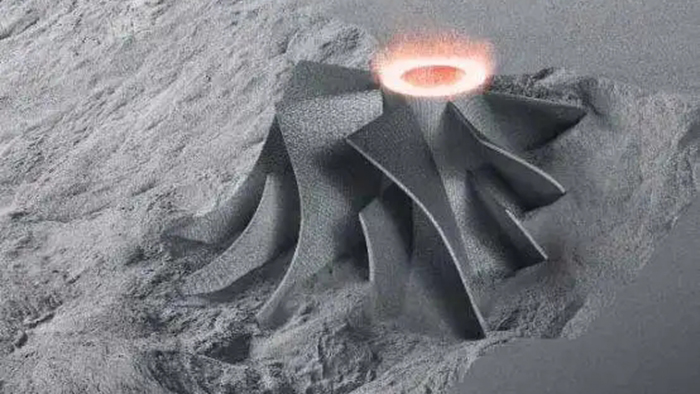

From rapid CNC machining to 3D printing, vacuum casting, sheet metal prototyping, injection moulding, and pressure die casting, Mastars delivers a variety of integrated solutions. These services cater to industries like automotive, medical devices, household appliances, and electronics, ensuring streamlined processes that prioritise consistency. This unified approach lays the groundwork for smooth digital integration.

By embracing Industry 4.0 technologies and maintaining rigorous quality standards, Mastars has revolutionised its production processes. Their digital-first approach enhances services such as CNC machining and 3D printing, improving transparency and efficiency across operations. This modernisation not only elevates process visibility but also supports the fast turnaround times that Mastars is celebrated for.

Switching from paper to digital documentation is transforming CNC machining for manufacturers across Australia. Research indicates that businesses adopting digital systems achieve up to 30% faster setup times and cut errors and rework by 25%. These gains are significantly improving productivity and profitability.

Digital documentation delivers three standout advantages that paper systems simply can't match. Real-time access ensures operators can instantly view the latest technical specs and quality checklists, eliminating delays and miscommunication. Automated compliance tracking simplifies audit preparation by centralising regulatory records, while collaboration tools help break down information silos, enabling faster problem-solving and smoother workflows.

As global supply chains demand greater traceability and process efficiency, staying competitive means embracing smarter systems. Experts recommend integrating digital documentation to optimise CNC processes and minimise operational risks.

For Australian manufacturers, the path forward is clear. Start by digitising the most critical CNC stages to see immediate benefits and create momentum for broader adoption. Look for systems that meet local data privacy standards and support metric measurements. While there’s an upfront cost for software and training, these investments are quickly offset by savings on maintenance, reduced storage needs, and fewer errors.

The future of CNC machining belongs to those who adopt digital documentation to improve efficiency and stay competitive. By making the shift now, your business can thrive in an increasingly digital manufacturing world.

Digital documentation makes it easier to comply with standards such as ISO 9001 and AS9100 by providing a clear, traceable record of machining processes, inspections, and updates. This approach ensures consistent control over processes while simplifying material traceability and revision tracking - both of which are essential for meeting these certification requirements.

With real-time monitoring and detailed documentation, manufacturers can more easily meet audit demands and uphold strict quality standards. This is particularly important in sectors like aerospace and medical devices, where precision and accountability are absolutely critical.

When adopting digital documentation systems in CNC machining, Australian manufacturers should focus on ensuring smooth integration with their existing machinery and IoT technologies. This approach enables real-time monitoring, quick identification of any deviations, and precise adjustments during operations - key factors for upholding high-quality production standards.

It’s also important to consider reliable and intuitive CNC controllers. These not only enhance operational stability but also improve efficiency. By automating processes and implementing digital controls, manufacturers can minimise errors, boost precision, and optimise workflows - perfectly in line with Australia's push towards advanced manufacturing and cost-effective solutions.

Lastly, manufacturers need to assess whether the system can scale and adapt to future growth or technological changes. This forward-thinking approach ensures the system remains valuable and efficient over the long run.

Integrating digital documentation systems with ERP and MES platforms simplifies CNC machining by allowing real-time data exchange and minimising errors caused by manual data entry. This integration ensures that critical information, like setup instructions and quality reports, remains consistent and accurate throughout the production process.

By synchronising documentation with manufacturing activities, these systems enhance operational transparency and automate updates. This leads to quicker decision-making, smoother workflows, and better quality control - key elements for refining CNC machining operations.