Modular prototyping is transforming manufacturing by driving faster, cost-efficient product development. These systems use cutting-edge techniques like 3D printing, modular CNC machining, and AI-driven design tools to create prototypes directly from digital designs. This enables industries like automotive, medical devices, and electronics to test and refine designs with precision while reducing costs and time-to-market.

Key Highlights:

Modular prototyping is undergoing a transformation, thanks to advancements that offer faster, more precise, and accessible solutions for modern product development.

Powder bed fusion has become essential for creating complex prototypes. This technique uses lasers to selectively melt metal or polymer powders, allowing the production of parts with intricate internal geometries that traditional methods struggle to achieve. Its precision is especially valuable in industries like aerospace and medical technology, where tight tolerances are non-negotiable.

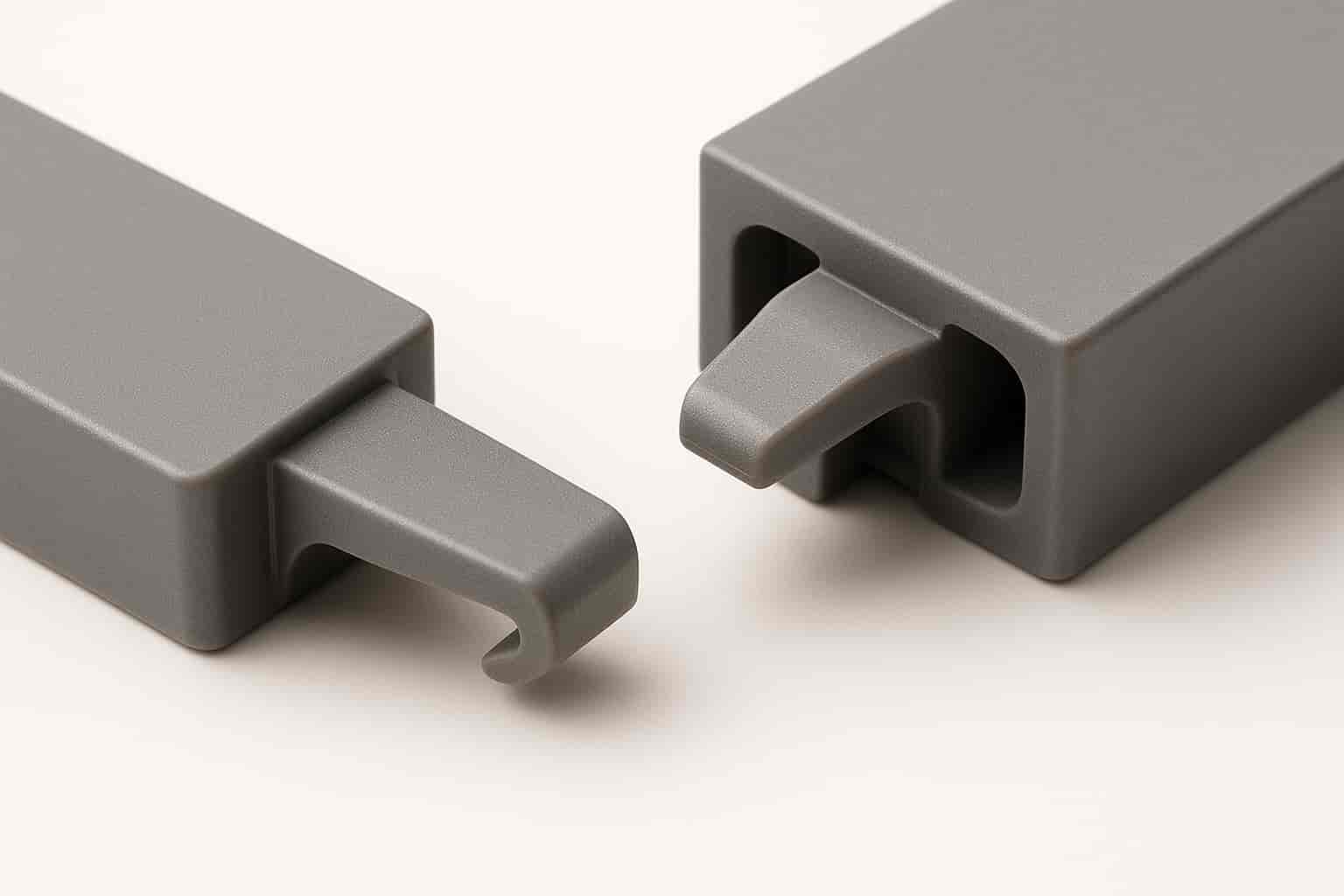

Multi-material systems push this further by combining different materials in a single print. This means prototypes can include rigid structural components alongside flexible elements like seals or gaskets - all in one process. By eliminating the need for separate manufacturing and assembly steps, these systems save both time and resources.

One of the biggest advantages of 3D printing is its speed. The layer-by-layer approach allows for rapid design iterations, enabling changes to be tested within hours rather than weeks. This is a game-changer in industries where hitting the market quickly can make or break success.

While 3D printing shines with complex geometries, modular CNC machining steps in to deliver precision and adaptability.

Modular CNC machining systems are designed for flexibility. They can be reconfigured to meet specific project needs, with adjustable tool changers, workholding systems, and even machine axes. This allows manufacturers to handle a wide variety of parts without requiring multiple dedicated machines.

For prototyping, this adaptability is crucial. A modular CNC system might produce precision aluminium parts for automotive applications in the morning and switch to machining polymer components for consumer electronics by the afternoon. This versatility not only reduces the need for extra machines but also saves on floor space and investment costs.

CNC machining's strength lies in its precision. While 3D printing excels at creating intricate shapes, CNC systems deliver superior surface finishes and dimensional accuracy. This makes them indispensable for prototypes requiring tight tolerances or specific surface characteristics.

On top of these physical advancements, artificial intelligence is reshaping how designs are created and validated.

Artificial intelligence is revolutionising prototyping by streamlining design and validation processes. AI-driven simulation drastically reduces the time needed to generate results - what once took hours or days can now be done in seconds. This speed allows engineers to explore multiple design variations within the same timeframe.

At the core of this technology are AI-powered Reduced Order Models (ROMs). These models, trained on extensive simulation data, quickly predict system behaviour under various conditions. This enables engineers to test different scenarios efficiently and identify optimal solutions without lengthy delays.

Generative design takes things a step further. By autonomously generating optimised design variations based on specific goals and constraints, it often uncovers innovative solutions that human designers might not consider. Instead of refining an existing design, generative design explores entirely new ways to meet functional requirements.

AI also significantly cuts down iteration cycles in rapid prototyping - by up to 25% - and reduces errors. Automated validation tools ensure that prototypes meet specifications in real time, minimising manual checks and costly rework. Meanwhile, Physics AI predicts physical outcomes quickly and accurately, using selective validation with traditional methods. This creates reusable AI models that lower costs and computation time for future projects.

Modular prototyping equipment is reshaping how products are developed and manufactured, offering faster processes and greater adaptability.

These systems streamline the journey from concept to prototype, allowing manufacturers to produce functional prototypes in record time. By using pre-tested and validated modules, development time is drastically reduced, letting engineers refine individual components instead of reworking entire systems.

Take technologies like 3D printing and laser cutting, for instance. They turn digital designs into physical prototypes in a flash, making it easier to test and tweak designs quickly. This agility not only speeds up the development process but also helps businesses launch products faster. Limited-scale rollouts and rapid iterations minimise risk, enabling companies to bring new products to market with confidence. Faster development naturally pairs with more flexible production strategies, giving businesses a competitive edge.

For small-batch production, modular prototyping equipment is a game-changer. Traditional manufacturing methods often aren’t cost-effective for smaller volumes, but modular systems allow manufacturers to scale incrementally without disrupting operations. This approach cuts downtime and keeps costs under control.

The beauty of modular design lies in its adaptability. Manufacturers can swap or add modules without overhauling the entire system. This flexibility supports continuous upgrades and makes small-scale market testing a practical option before committing to full-scale production. It’s a smart way to innovate while managing risks and resources effectively.

Mastars showcases how a customised and integrated approach to modular prototyping can directly benefit Australian manufacturers, streamlining processes and delivering high-quality results.

By combining advanced prototyping technologies with strict quality and cost controls, Mastars helps Australian businesses optimise their manufacturing processes and stay competitive in global markets.

Mastars provides a One Stop Solution for mechanical components, covering every stage from initial prototypes to full-scale production. Their modular system brings together a range of prototyping technologies under one roof, including rapid CNC machining, 3D printing, vacuum casting, and sheet metal prototyping.

For example, their vacuum casting process can produce 10–20 parts in just a few days, making it ideal for low-volume production runs. This method offers a wide range of material simulations, replicating textures like ABS, PP, and rubber-like finishes with high precision. It’s particularly suited for industries like automotive, medical devices, and 3C electronics, where accurate prototypes and quick turnarounds are crucial.

Mastars’ CNC machining, supported by international certifications like ISO 9001 and AS9100, ensures prototypes are production-ready. Their stringent quality control processes, such as PPAP, ISIR, and PDCA, further enhance reliability. By integrating these technologies, Mastars significantly reduces the time it takes for Australian manufacturers to transition from prototype to market.

"The fidelity of early-stage prototypes is inversely proportional to overall project risk."

- Australia's renowned CSIRO, Industry 4.0 report

This seamless integration delivers practical and measurable benefits for Australian manufacturers.

Mastars caters to industries like automotive, medical devices, 3C electronics, and household appliances, tailoring their modular solutions to meet the unique needs of each sector. This approach is particularly useful for industries in Australia that require high precision and adaptability.

Their scalable system supports everything from single prototypes to limited production runs, making it easier for Australian businesses to test market feasibility before committing to large-scale production. This flexibility is invaluable for reducing risks and ensuring a smoother path to market.

Additionally, Mastars provides expert guidance on material selection, design optimisation, and post-processing techniques. This consultative approach not only improves the quality of prototypes but also enhances the overall development process.

"Our goal is not merely to manufacture a part for you but to act as your extended R&D team and reliable manufacturing capacity backup, working together to accelerate the transformation of innovative ideas into successful products."

- Mastars

For Australian manufacturers, Mastars’ solutions offer access to cutting-edge prototyping technologies without the need for significant capital investment. This advantage allows businesses to bring products to market faster while maintaining high standards of quality and cost efficiency.

Manufacturing is evolving at an incredible pace, with modular prototyping technologies driving the shift towards more efficient and environmentally friendly production methods. These advancements are transforming how Australian manufacturers develop products, enabling quicker innovation and helping businesses stay competitive.

Take multi-material 3D printing systems, for example. These systems can produce prototypes with different material properties in a single build. That means no more multiple prototyping runs or tedious assembly processes, cutting down both development time and costs. Similarly, modular CNC machining systems are making it easier for manufacturers to switch between projects. By reconfiguring setups quickly, they can maximise equipment use and minimise downtime. These advancements are laying the groundwork for a digital transformation in prototyping.

Perhaps the most game-changing development is the integration of artificial intelligence and simulation-based design automation. These tools allow manufacturers to refine and optimise designs before even creating a physical prototype. The result? Less material waste, faster iteration cycles, and the ability to respond to market demands more quickly than ever.

Modular prototyping also supports small-batch production, which is ideal for creating localised and sustainable supply chains. This approach meets local demand without the need for maintaining large, costly inventories.

To fully leverage these technological advancements, businesses need to incorporate modular prototyping into their long-term strategies. Australian manufacturers, in particular, must adopt comprehensive systems that combine proven methods with cutting-edge technologies. This strategy ensures faster iteration, improved market responsiveness, and sustainable growth. By aligning with this forward-looking approach, which has already seen success in platforms like Mastars, manufacturers can meet increasingly complex market demands while keeping costs and environmental impact in check.

Modular prototyping equipment speeds up product development by allowing teams to quickly assemble and test interchangeable components. This method makes it easier to refine designs through faster iterations and adjustments, cutting down the time needed to perfect a product.

It’s also a cost-effective strategy. By reusing modules across various projects and incorporating standardised parts, manufacturing becomes simpler and more compatible with automation. This blend of efficiency and reduced expenses has made modular prototyping a key asset in today’s industries.

Integrating AI with simulation-based design automation has reshaped the prototyping process, making it faster and more efficient. AI takes over repetitive tasks, such as generating design alternatives and performing simulations, enabling quicker iterations and more accurate virtual testing. This not only reduces the workload for engineers but also shortens development cycles.

With these technologies in play, manufacturers can make smarter decisions, cut costs, and push the boundaries of innovation. This synergy is revolutionising prototyping, turning it into an essential strategy for industries striving to stay ahead in today’s fast-moving manufacturing world.

Modular prototyping has reshaped the way small-batch production works, bringing speed, adaptability, and affordability to the process. It gives manufacturers the ability to quickly test and tweak designs, helping ensure products meet quality benchmarks while cutting down on potential defects.

For manufacturers in Australia, this method makes it easier to respond swiftly to changing market demands and stick to tighter production schedules. By reducing waste and making better use of resources, it also streamlines the production of top-notch components. These benefits are helping drive creativity and keep Australian manufacturing competitive on the global stage.