Snap-fit joints are a reliable and cost-effective way to assemble plastic parts in injection moulding. They interlock components through elastic deformation, eliminating the need for screws or adhesives. Here's what you need to know:

To ensure snap-fit joints perform reliably over time, careful attention to design details is essential. Three key areas form the foundation of a successful snap-fit joint: selecting the right materials, designing appropriate geometry, and managing tolerances and stress distribution. When done right, these elements create joints that stand up to repeated use and varying conditions.

The material you choose plays a critical role in how well your snap-fit joint will hold up over time, especially under repeated use. Thermoplastics are a popular choice because they offer the flexibility needed for assembly and the strength required for durability.

When selecting a material, think about factors like the operating temperature range, the number of assembly cycles expected, exposure to chemicals, and the need for UV resistance. Matching the material to the application ensures long-term reliability.

The geometry of a snap-fit joint directly affects how it functions and how easily it can be manufactured. There are three main types of snap-fit geometries, each suited to specific needs:

Choose the geometry based on the assembly process and user requirements. For manual assembly, designs that require moderate force and provide tactile feedback are best. Automated processes, on the other hand, can handle higher forces but demand consistent and predictable behaviour.

Accurate tolerances and stress management are essential for ensuring consistent performance across production runs. However, tighter tolerances often mean higher manufacturing costs, so finding the right balance is key.

Critical dimensions include the deflection distance, engagement depth, and contact surfaces. A deflection tolerance of ±0.05mm usually works well for most applications, though some cases may call for even tighter controls.

To avoid stress concentrations that could lead to cracking, avoid sharp corners and abrupt cross-sectional changes. Use generous fillet radii at the base of cantilever beams and ensure smooth transitions between sections to distribute stress more evenly.

Deflection angles also need careful consideration. Thermoplastics generally perform well with deflection angles of 20-30 degrees. Exceeding these limits increases stress, reducing the joint’s fatigue life. Always design with a safety margin to account for variations in manufacturing and material properties.

In injection moulding, draft angles are crucial for easy mould release. Non-critical surfaces typically require a draft angle of 0.5-1.0 degrees, while critical engagement surfaces may need zero draft. This can increase tooling costs but ensures proper joint function.

Finally, consider how temperature changes affect material properties. Thermoplastics become more flexible in high heat and more brittle in cold conditions. Design tolerances to accommodate these shifts, ensuring reliable performance whether the product is used in the heat of Darwin or the chill of Melbourne’s winters.

These design principles form the foundation for creating durable, reliable snap-fit joints that meet the demands of their intended applications.

This checklist outlines essential elements for creating durable and functional snap-fit designs, balancing technical specifications with practical manufacturing and assembly needs.

The strength of snap-fit joints depends on thoughtful design choices that evenly distribute stress and minimise the risk of failure:

The choice of materials and manufacturing processes plays a pivotal role in ensuring the joint's performance over time:

After selecting appropriate materials and processes, confirm that assembly procedures align with the intended design to avoid performance issues.

Once the design is optimised, consider these factors to ensure smooth assembly and long-term reliability:

Even experienced designers can make errors when working on snap-fit joints. Catching these mistakes early can save time, money, and frustration later.

Sharp edges and sudden transitions can create stress hotspots, which often lead to early failure. For instance, cantilever beams with sharp internal corners where they meet the main body are a common issue. These corners tend to concentrate forces in small, vulnerable areas. Similarly, using fillet radii that are too small can amplify stress. Another frequent problem is designing beams with incorrect proportions, making them overly stiff and unable to distribute stress effectively.

To fix these issues, opt for larger fillets, tapered profiles, and wider beams instead of thicker ones. These adjustments help spread stress more evenly. Additionally, tweak beam dimensions to improve how loads are distributed across the joint.

Next, let's explore how poor material choices can undermine your design.

Selecting the wrong material - whether due to cost or availability - can compromise the performance of snap-fit joints. Brittle materials like unmodified polystyrene tend to crack under repeated flexing, while stiff options like glass-filled nylon may develop stress cracks. Environmental factors also matter. A material that performs well in controlled settings might become brittle when exposed to UV light, harsh chemicals, or extreme temperatures. In reinforced plastics, improper fibre orientation can create weak spots, further weakening the joint.

To avoid these pitfalls, choose materials that balance flexibility and strength while considering the full service environment. Think about temperature fluctuations, chemical exposure, and UV resistance. If you're using reinforced materials, collaborate with your injection moulder to optimise fibre orientation and processing conditions for better durability.

Finally, let’s address how assembly and tooling challenges can affect your design’s success.

Assembly problems often arise when practical considerations are overlooked. Snap-fits that require awkward handling or excessive force can slow down both manual and automated assembly. Limited access for tools during assembly or disassembly can also lead to maintenance headaches and higher service costs. On top of that, tolerance stack-up can cause inconsistent engagement, while overly complex geometries may demand intricate tooling or create undercuts that make part ejection difficult. Poor part orientation during moulding can further complicate matters, leading to issues like flash or dimensional inconsistencies.

To resolve these challenges, design snap-fits with realistic assembly forces that align with the intended user and application. Include features that make engagement and disassembly straightforward and accessible. Perform tolerance analyses early in the design process to account for manufacturing variations. Collaborate with tooling engineers to address moulding challenges, ensuring proper part orientation and smooth production. For automated assembly, consider adding alignment features and positive stops to keep operations efficient and reliable.

Understanding the different types of snap-fit joints and their manufacturing methods can help you make informed decisions based on factors like cost, quality, and production timelines. Each joint type has distinct advantages, and the manufacturing process you choose will play a critical role in achieving your desired outcomes. This section builds on the design fundamentals already covered and dives deeper into practical manufacturing considerations.

Choosing the right snap-fit design depends on factors like required strength, ease of assembly, and manufacturing constraints.

| Joint Type | Strength | Ease of Assembly | Tooling Complexity | Best Applications |

|---|---|---|---|---|

| Cantilever | Moderate to high | Easy – single direction engagement | Low to moderate | Electronics housings, battery covers, automotive trim |

| Annular | High – distributes stress evenly | Moderate – requires axial force | Moderate to high | Pipe fittings, bottle caps, cylindrical assemblies |

| Torsional | Very high – excellent retention | Difficult – requires twisting motion | High – complex geometry | Bayonet connections, lens mounts, secure closures |

Cantilever snap-fits are an excellent choice for applications where straightforward assembly and disassembly are priorities. Their beam-like structure is cost-effective to mould but may be prone to stress concentrations at the root. Annular snap-fits, on the other hand, provide strong retention by evenly distributing stress around the circumference, making them ideal for applications requiring a secure fit. However, they demand precise tooling and can be more challenging to demould. Torsional snap-fits provide the highest retention strength but are more complex to assemble, making them suitable for high-security or specialised applications.

For manual assembly, cantilever designs are often the easiest to manage. Automated systems, however, can efficiently handle the more intricate requirements of annular and torsional designs.

The choice of manufacturing method significantly impacts costs, lead times, and the ability to prototype effectively.

| Factor | Injection Moulding | 3D Printing |

|---|---|---|

| Dimensional Tolerances | ±0.05–0.1 mm | ±0.1–0.3 mm |

| Setup Costs | A$5,000–A$50,000+ for tooling | A$0–A$500 for setup |

| Unit Cost (1,000 parts) | A$0.50–A$5.00 each | A$2.00–A$20.00 each |

| Unit Cost (100,000 parts) | A$0.10–A$1.00 each | A$2.00–A$20.00 each |

| Lead Time | 4–12 weeks for tooling | 1–3 days for parts |

| Material Options | Extensive – optimised polymers | Limited – fewer engineering grades |

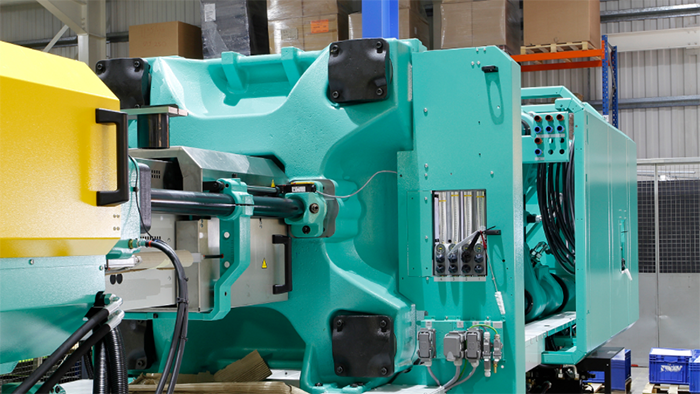

Injection moulding becomes the more economical option when producing larger quantities - typically over 1,000 to 5,000 parts, depending on the design complexity. This method offers tight tolerances, ensuring consistent performance across production runs, and supports a wide range of materials, including advanced polymers with properties like fatigue resistance or chemical compatibility.

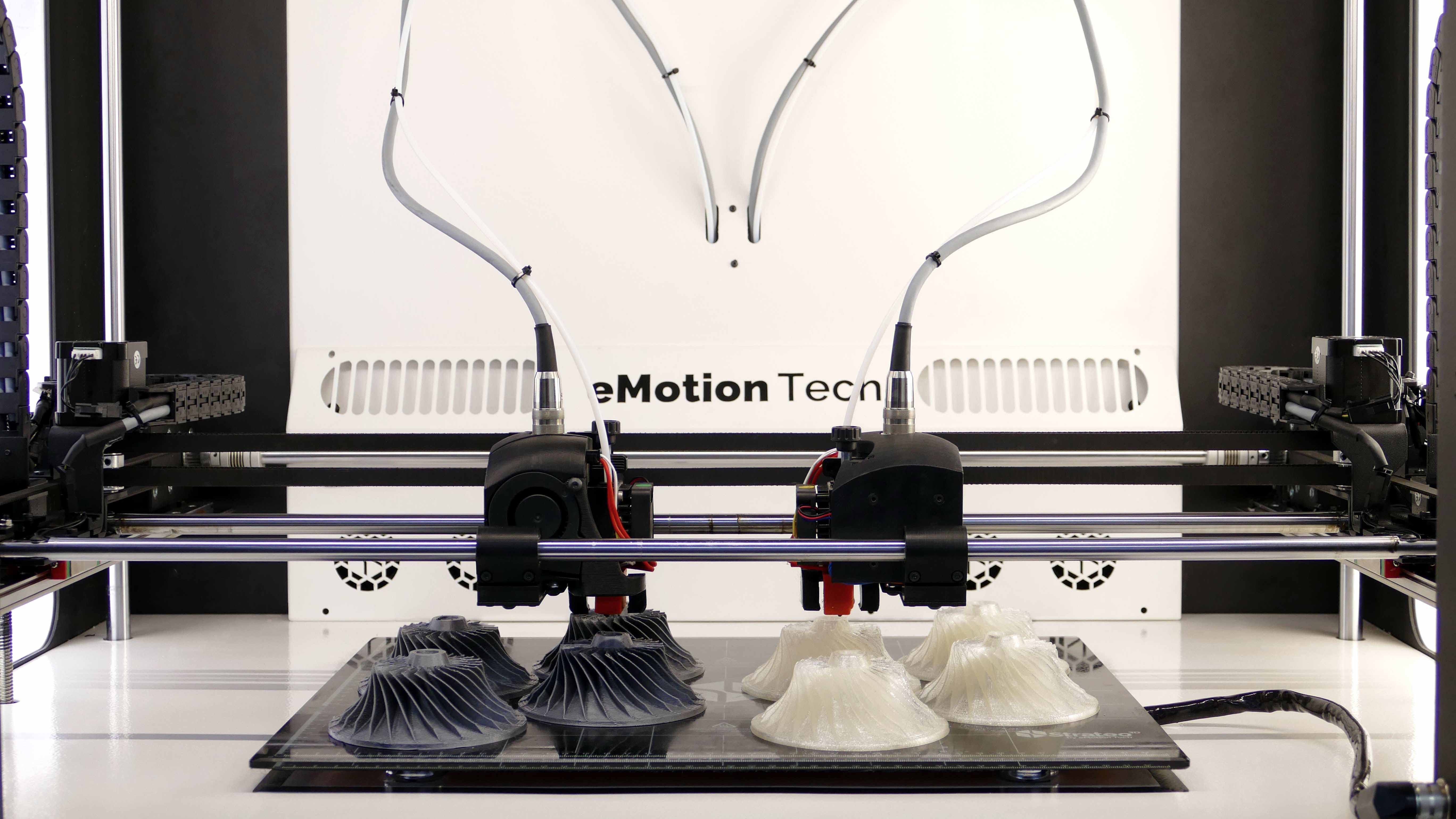

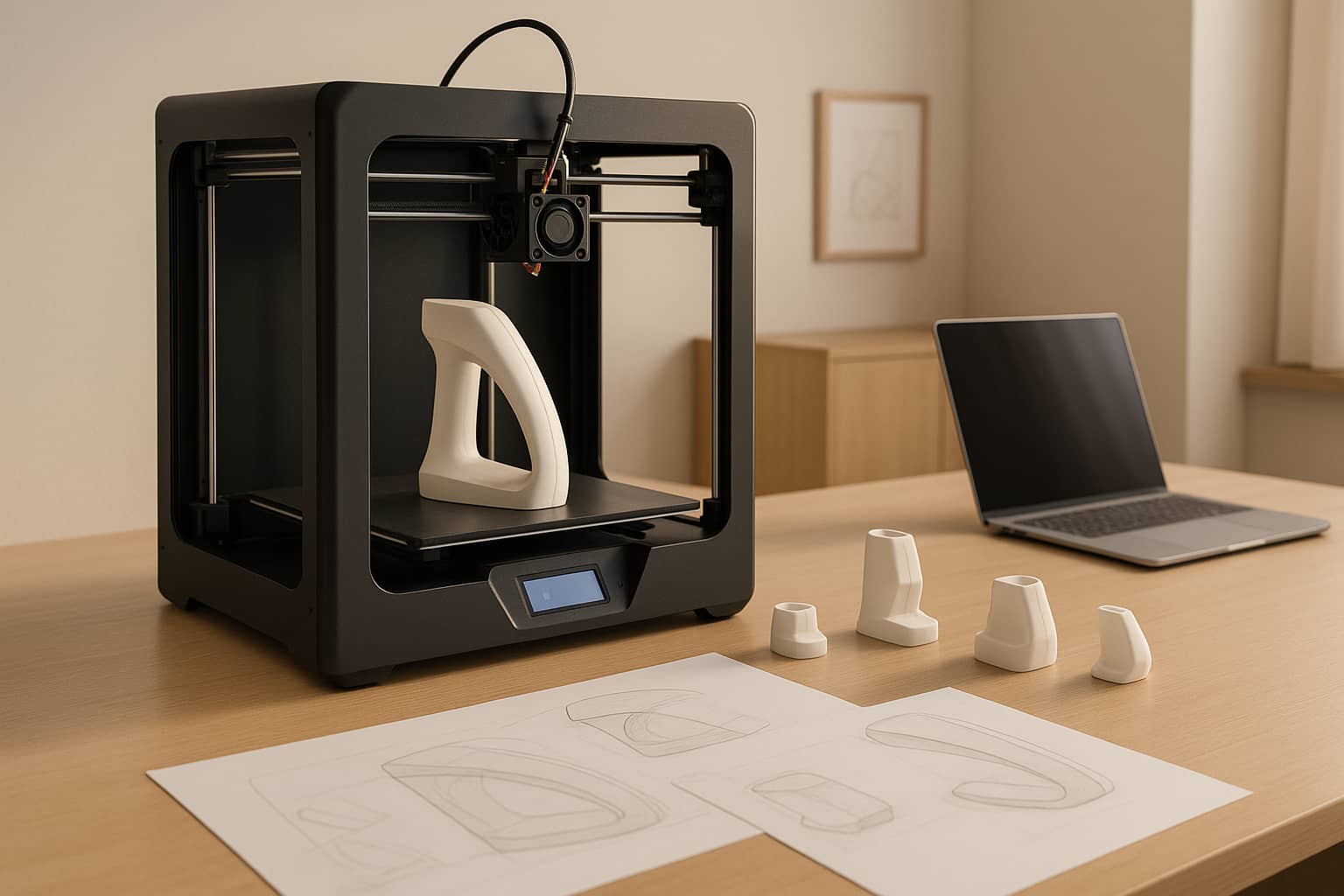

On the other hand, 3D printing is ideal for prototyping and early design iterations. Its quick turnaround - often producing parts in just a few days - can significantly speed up the development process. However, the layer-by-layer manufacturing method can limit the durability of snap-fit joints and may result in less consistent dimensions compared to injection moulding.

A common approach is to use 3D printing during the design phase to test and refine geometries before committing to injection moulding for mass production. This is particularly useful for complex designs like torsional snap-fits, where injection moulding generally delivers better surface finishes and dimensional accuracy. While 3D printing allows for rapid experimentation, injection moulding ensures the durability and precision needed for large-scale production.

Mastars provides comprehensive services for developing snap-fit joints, seamlessly combining design, prototyping, and production. By following established design principles, they ensure a smooth process from initial concept to large-scale manufacturing, delivering top-notch snap-fit joint components.

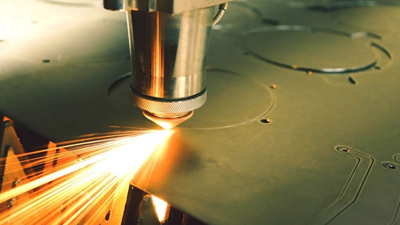

To refine and validate designs early, Mastars uses advanced techniques like 3D printing, CNC machining, and sheet metal prototyping. Once the design is finalised, they transition to full-scale production with methods such as injection moulding and vacuum casting, ensuring efficiency and precision.

Mastars brings a wealth of experience from industries including automotive, medical, and domestic applications. Their integrated manufacturing approach, combined with rigorous quality control and strict compliance with industry standards, ensures they meet the demanding requirements of snap-fit joint applications.

Designing effective snap-fit joints requires careful attention to material selection, geometry, and tolerance control. Thermoplastics, known for their flexibility and durability, are commonly used to ensure reliable joint performance over repeated assembly cycles.

Geometry is just as important in determining a joint's performance. Factors like beam thickness, deflection angles, and stress relief features all contribute to a robust design. Gradual transitions, rather than sharp corners, are essential to minimise stress concentrations and reduce the risk of cracking during use.

Tolerance control is another critical aspect. Striking the right balance is key - tight tolerances can drive up production costs unnecessarily, while loose tolerances may weaken the joint's holding strength. Achieving this balance requires a clear understanding of the material's properties and the specific requirements of the application.

A systematic design checklist can save time and money by preventing costly mistakes. Overlooking small details during the design phase often leads to expensive tooling modifications and production delays later on.

The choice of manufacturing method also has a major impact on both prototyping and final production. 3D printing is ideal for rapid iterations, while injection moulding provides the precision and surface finish needed for production-quality components. Selecting the right method ensures a smoother development process and helps control costs.

Collaborating with experienced manufacturers like Mastars can make all the difference. Their expertise in prototyping and production ensures that designs are manufacturable while maintaining their intended functionality. This integrated approach is especially valuable when transitioning from initial design to full-scale production, where balancing design intent with manufacturing efficiency is crucial.

When choosing between injection moulding and 3D printing for snap-fit joints, it’s essential to weigh factors like production volume and design complexity.

Injection moulding shines when it comes to large-scale manufacturing. It offers excellent strength, durability, and cost-effectiveness for producing items in bulk. On the flip side, 3D printing is a great choice for smaller production runs, rapid prototyping, and complex designs. Its flexibility and quicker iteration process make it a strong contender for projects requiring frequent design tweaks.

That said, while 3D printing provides greater creative freedom, the parts it produces often lack the strength and long-term reliability of injection-moulded components. For high-stress applications, injection moulding is generally the better option. Ultimately, the right choice depends on your project’s scale, budget, and performance needs.

To keep your snap-fit joints working reliably in different temperature conditions, it's crucial to adjust tolerances to accommodate thermal expansion and contraction. This ensures the joints remain functional, no matter the temperature shifts.

Selecting materials with low thermal expansion coefficients and strong thermal stability can significantly improve durability. You can also include features like flexibility points or stress-relief areas to minimise the effects of environmental changes, helping the joints perform consistently in various scenarios.

When designing snap-fit joints, a few common errors can compromise their strength and reliability. A major issue is incorporating sharp corners at the base of cantilevers. These corners tend to concentrate stress, making the joint more prone to failure. Another frequent mistake is improper tapering or poorly chosen dimensions, which can create uneven stress distribution and weaken the joint.

To tackle these challenges, adding fillets at stress-prone areas is a simple yet effective solution. Fillets help to spread out stress more evenly, reducing the risk of cracks or breaks. Similarly, tapering the cantilever's cross-section can ensure a more balanced stress distribution, enhancing the joint's overall performance.

It's also important to account for thermal expansion by maintaining proper tolerances. Avoiding features that are either too thin or excessively thick can further improve the joint's durability. These design tweaks not only make the joint more robust but also streamline manufacturing, saving time and reducing costs in the long run.