Rapid prototyping helps manufacturers test and refine designs faster, reducing costs and improving production efficiency. By creating physical models early in the design phase, it allows teams to address potential manufacturing issues, validate designs, and optimise processes before full-scale production. When combined with Design for Manufacturing (DFM) principles, it ensures products are easier and less expensive to produce while meeting high-quality standards.

By integrating rapid prototyping into DFM, Australian manufacturers can improve product quality, reduce time-to-market, and stay competitive in industries like automotive, medical devices, and household appliances.

Traditional manufacturing methods often involve weeks of tooling delays, which can slow down design iterations. In contrast, rapid prototyping provides physical models almost instantly. This speed allows teams to quickly refine their designs. For example, if a prototype highlights a misalignment or a mechanism that doesn’t work as intended, engineers can promptly adjust the digital design and produce an updated prototype far faster than with older methods.

This quick feedback loop is particularly valuable for complex assemblies. For Australian manufacturers collaborating with international clients across various time zones, the ability to incorporate feedback without delays is a game changer. It not only improves design precision but also helps manage development costs effectively.

The efficiency of rapid prototyping goes hand-in-hand with Design for Manufacturability (DFM) principles, focusing on reducing waste and making better use of resources. The financial advantages extend beyond just faster timelines. Studies indicate that rapid prototyping can halve development times and reduce manufacturing costs by up to 90%.

This cost reduction is largely due to efficient material usage. Traditional subtractive methods, like machining, often result in significant material waste, as parts are carved from solid blocks. In contrast, rapid prototyping techniques, such as 3D printing, build parts layer by layer, using only the material needed and minimising waste.

"Compared to traditional manufacturing, 3D printing has the potential to reduce waste and materials costs by almost 90% while also cutting manufacturing energy use in half." - U.S. Department of Energy

Another key benefit is the ability to identify potential flaws during the prototyping stage, which can save companies from expensive fixes in full-scale production.

"Early flaw detection avoids costly mistakes and rework." - BigRep

On-demand prototyping also eliminates the need for maintaining large inventories of test parts that may become obsolete. Instead, manufacturers can produce parts as needed. Companies like Mastars provide an integrated approach to prototyping and production, enabling Australian manufacturers to take full advantage of these benefits while ensuring a smooth transition to mass production.

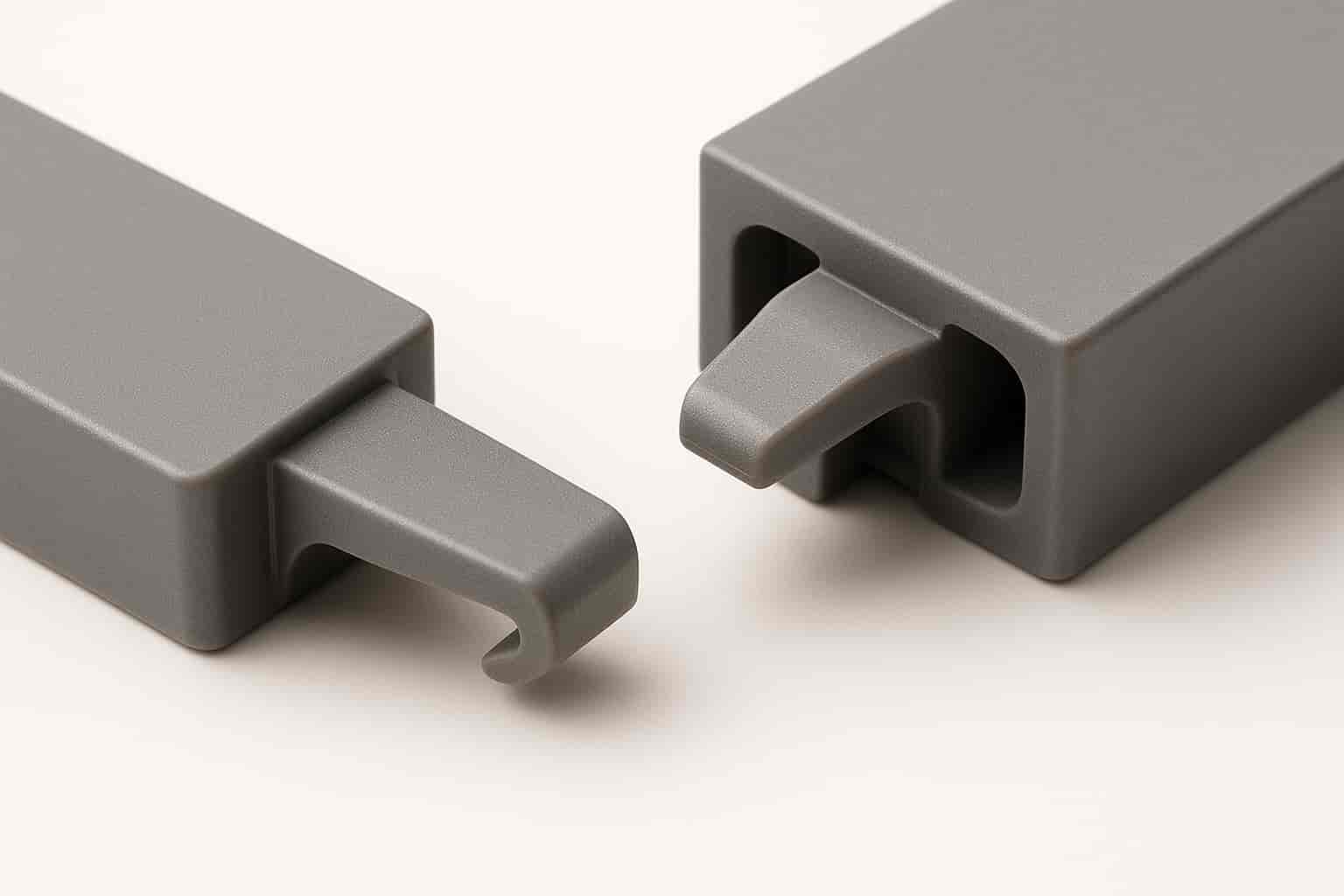

Prototyping has revolutionised the way engineers validate designs, offering a hands-on approach that goes beyond computer simulations. With rapid prototyping, teams can create physical models to test form, fit, and function, allowing them to spot assembly issues, check component compatibility, and verify specifications before investing in expensive tooling.

This process is especially important for consumer-facing products in Australia, where aesthetics and ergonomics can make or break market success. Designers can evaluate how a product looks, how its components align, and whether it operates reliably - all in one go. For industries like automotive and medical devices, where precision is critical, fit testing ensures assembly accuracy and confirms that tolerances align with manufacturing requirements.

When it comes to functionality, prototypes allow teams to test moving parts, joint articulation, and mechanical interactions. These evaluations ensure that the product performs as intended, feeding valuable insights back into the design process to improve manufacturability and overall performance.

Prototypes also shine when subjected to real-world conditions. In Australia, where products face diverse environmental challenges, testing under actual conditions ensures designs can handle everything from tropical humidity in Queensland to the blistering heat of the Northern Territory.

Environmental testing becomes much simpler with rapid prototyping. Products can be exposed to temperature shifts, humidity, UV rays, and mechanical stress to assess their durability and performance over time. This kind of testing is crucial for Australian manufacturers aiming to ensure their products remain reliable across the country’s varied climates.

Regulatory compliance is another area where prototypes play a key role. Many Australian standards require physical testing before a product can be approved for sale. By creating functional prototypes early, manufacturers can conduct preliminary compliance tests, identify potential issues, and make necessary adjustments long before final production begins.

Prototypes also enable user testing that digital models simply can’t replicate. Real users can interact with physical models, offering feedback on usability, comfort, and functionality. This hands-on interaction not only helps meet compliance requirements but also uncovers design flaws early, allowing teams to refine the product for better manufacturability and user satisfaction.

Rapid prototyping has become a driving force behind design innovation and small-scale production adaptability, thanks to its ability to support faster design changes and improved validation.

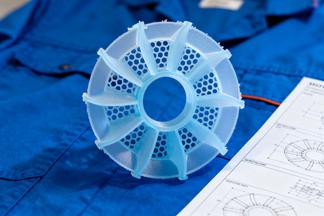

Australian manufacturers are now embracing rapid prototyping to create intricate and highly detailed designs that traditional methods simply can't produce cost-effectively. Unlike conventional techniques, which often impose strict design constraints, modern prototyping technologies allow for almost limitless design possibilities. This means designers can develop parts with intricate features and complex geometries that were once impossible to achieve.

Take 3D printing, for example - it’s particularly effective for producing components with internal features, undercuts, and thin walls. These details are notoriously difficult to achieve with traditional machining. For small production runs (up to 80 parts), additive manufacturing offers a cost-efficient solution. However, for larger volumes exceeding 100 parts, CNC machining often becomes the more economical choice.

Different 3D printing methods also bring unique capabilities to the table. Stereolithography (SLA) is renowned for its high resolution, precision, and smooth surface finishes, making it ideal for detailed prototypes. On the other hand, Selective Laser Sintering (SLS) is better suited for creating strong, functional parts that can be used to test complex assemblies before committing to expensive tooling. This adaptability is especially beneficial for industries like aerospace and medical devices, where intricate internal channels and fine details are often essential.

By enabling these complex geometries, rapid prototyping also opens the door to agile and efficient small-scale production.

For Australian manufacturers, rapid prototyping has revolutionised small-volume production, especially when it comes to creating specialised products tailored to local markets. Its iterative nature allows engineers to experiment with multiple design concepts quickly and affordably, cutting down on risks and avoiding the steep costs associated with traditional tooling.

This is particularly advantageous for companies serving niche markets. For instance, manufacturers producing specialised mining equipment for the Pilbara region can use rapid prototyping to create limited production runs. This approach allows them to test market interest, gather user feedback, and refine their designs - all without the hefty upfront investment required by traditional methods like injection moulding or die casting.

The material flexibility of rapid prototyping further enhances its appeal. By selecting materials with specific properties - such as optical clarity, mechanical strength, or thermal resistance - companies can simulate real-world conditions during testing. For example, a manufacturer designing outdoor equipment for Australia's extreme climate can evaluate factors like UV resistance and thermal expansion before committing to large-scale production.

Companies like Mastars utilise a combination of rapid prototyping techniques, including 3D printing, CNC machining, and vacuum casting, to meet diverse project requirements. This integrated approach allows Australian manufacturers to choose the most suitable method for their needs. Whether it’s the geometric freedom of 3D printing for intricate internal structures or the robust material options of CNC machining for durable prototypes, this flexibility ensures a seamless transition from design to full-scale production. By reducing manufacturing constraints, rapid prototyping ultimately makes it easier to move from concept to reality.

Bringing rapid prototyping into Design for Manufacturing (DFM) processes is reshaping how products are developed, allowing for quicker iterations, reduced costs, and real-world testing before full-scale production begins.

Rapid prototyping simplifies DFM by enabling early-stage validation and handling complex geometries with ease. It allows manufacturers to simultaneously test a design's form, fit, and function, spot potential production issues before they escalate into costly problems, and make swift design adjustments based on market feedback. This is especially useful for Australian industries catering to specialised markets, where traditional high-volume manufacturing isn't always practical. This approach lays the groundwork for further breakthroughs in design.

The flexibility in materials and geometric possibilities opens up opportunities for innovation - whether it's creating intricate internal channels for medical devices or building durable mining equipment that can withstand Australia's harsh conditions - all while staying cost-efficient. The ability to move seamlessly from prototype to small-scale production has been a game-changer for companies exploring niche markets or delivering tailored solutions.

This efficiency has increased the demand for integrated manufacturing solutions. For Australian manufacturers, working with partners like Mastars simplifies the journey from prototype to full production. Their expertise spans rapid CNC machining, 3D printing, vacuum casting, and sheet metal prototyping, offering the versatility needed to meet a variety of project demands. This all-in-one approach ensures consistency and quality, whether you're producing automotive parts, medical devices, or household appliances.

As the manufacturing landscape continues to evolve, the partnership between rapid prototyping and DFM is set to grow even stronger. Companies embracing this integrated model are better equipped to respond to market needs, speed up their time-to-market, and maintain a competitive edge in a fast-changing industry.

Rapid prototyping is a game-changer for cutting manufacturing costs, especially during the early stages of product development. By eliminating the need for expensive moulds and tooling, it significantly reduces upfront expenses. It also shortens production timelines, making it easier to test and refine designs quickly without lengthy delays. On top of that, this approach helps minimise material waste by allowing precise testing and adjustments before moving to full-scale production. The result? A smoother, more efficient, and cost-effective manufacturing process.

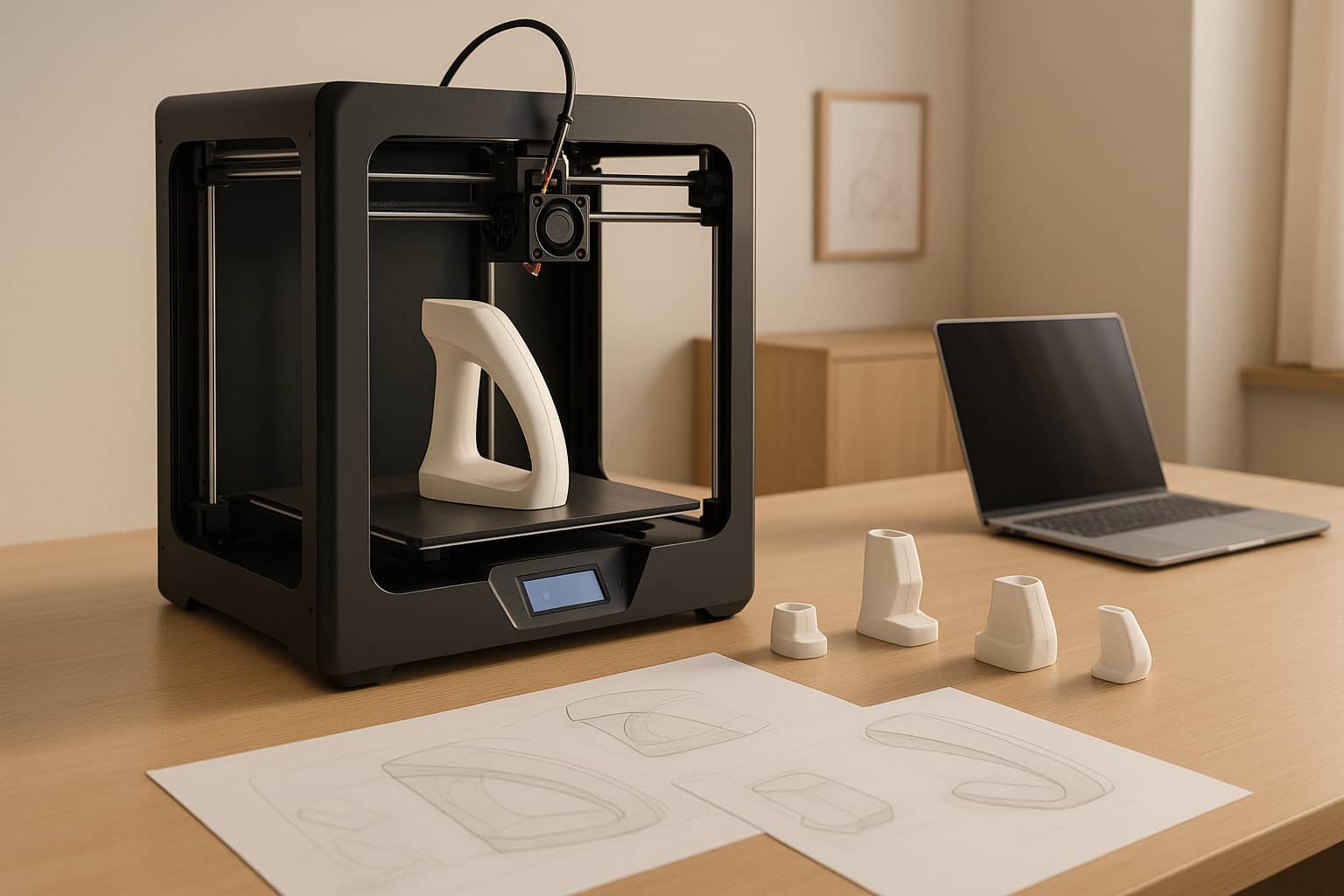

CNC machining and 3D printing represent two distinct methods for rapid prototyping, each suited to different needs. CNC machining, a subtractive process, involves carving parts from solid materials. This method excels in delivering high precision, smooth finishes, and tight tolerances, making it perfect for prototypes that need to meet strict mechanical standards or undergo durability testing.

In contrast, 3D printing is an additive process, where parts are built layer by layer. This approach shines when it comes to design flexibility and quicker production times. It's especially useful for crafting intricate geometries or producing low-volume prototypes. Both techniques are invaluable tools for speeding up product development, with the choice depending on the specific demands of the project.

Rapid prototyping gives Australian manufacturers in specialised markets a real edge by allowing quick design updates and practical testing. This process helps fine-tune products to meet specific customer needs and respond to shifting market trends with agility.

It also enables the development of complex designs and precision-engineered components, which are crucial for thriving in niche industries. By cutting down on development time and enhancing product uniqueness, rapid prototyping not only keeps manufacturers competitive but also ensures production processes remain efficient and cost-conscious.