What Is Sheet Metal Fabrication?

Sheet metal fabrication is a cold?working process for sheets typically ≤ 6 mm thick. It combines operations such as shearing/blanking, laser cutting or CNC punching, bending, welding or mechanical assembly, and surface finishing. A key characteristic is that a part retains a uniform material thickness throughout.

Mastars’ rapid prototyping service tailors processes to your design goals, validates form?fit?function quickly, and lays a sound foundation for future mass production.

End to End Process

Below is the standard Mastars workflow from drawing to shipment. Depending on the design, some steps may be combined.

1) Drawing & DFM Preparation

- Customers provide 2D/3D files or samples. We accept STEP/IGES/DWG/DXF/PDF.

- Mastars engineers measure, analyze and create manufacturing and assembly drawings, offering DFM guidance on bend radii, hole?to?edge distances, pressed?in hardware, and tolerances.

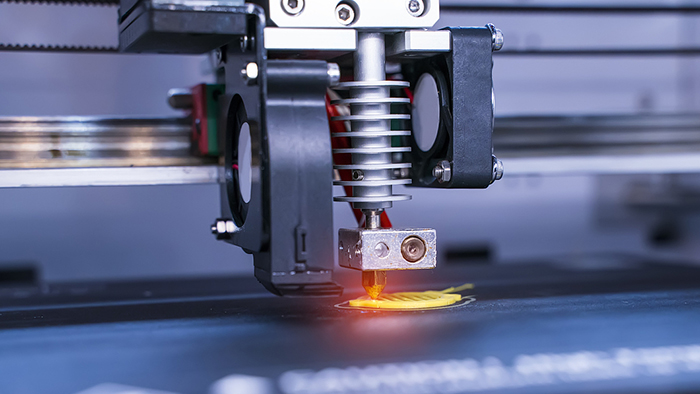

2) Cutting — Laser vs CNC Punching

- Laser cutting produces burr?free edges on carbon steel, stainless steel and aluminum with high accuracy and excellent edge quality — ideal for complex contours and small batches.

- CNC turret punching is optimal for thin sheets (typically ≤ 2.5 mm) with high hole counts, louvers, embosses or forms that benefit from tooling. For medium/large batches, it offers cost advantages and speed.

When to choose which:

- Complex profiles, short runs, mixed materials → Laser

- Many repeated holes, special forms, larger batches → CNC Punching

3) Bending & Forming

- Performed on CNC press brakes for speed and repeatability.

- Typical guidance: respect minimum flange length, bend reliefs near corners, and a suitable bend radius/K?factor for the alloy and thickness.

- We hold tight angle and dimensional tolerances with appropriate tooling and off?set compensation.

4) Welding & Mechanical Assembly

- Joining methods include TIG (GTAW), MIG (GMAW), and spot (resistance) welding, plus screws, rivets, and PEM/clinching hardware.

- After welding, seams are ground and polished for structural integrity and aesthetics.

- Sub?assemblies can be fully built with inserts, hinges, gaskets and fasteners.

5) Surface Finishing

- Electrostatic powder coating (common for carbon steel): pretreat → degrease/rust removal → surface conditioning/cleaning → phosphating → spray → high?temperature curing. Typical film thickness 60–100 μm; durable, cost?effective and corrosion?resistant.

- Liquid paint (suitable for large or temperature?sensitive parts): primer + topcoat; flexible color matching (RAL/Pantone), convenient for oversized parts.

- Other options on request: passivation, brushing, anodizing (for Al), plating, silk?screening and laser marking.

6) Quality Assurance & Inspection

- 100% visual inspection before packing; critical dimensions verified per drawing.

- Inspection data and certificates (e.g., COA, measurement reports) can be provided.

- Quality systems align with international standards and automotive expectations.

7) Packaging & Shipping

- Packaging methods confirmed with the customer representative; options include EPE foam, bubble wrap, VCI bags, carton + pallet, and custom crates.

- Shipping via air express, air freight, or sea freight per agreed Incoterms. Records are retained for traceability and reconfirmation.

Capabilities & Tolerances (Typical)

Actual capability depends on geometry, material and finish. Share your files for a fast DFM review.

| Category | Typical Range/Notes |

|---|---|

| Materials | Carbon steel (SPCC/SECC/SGCC), Stainless (SUS304/316), Aluminum (5052/6061), Copper/Brass |

| Sheet thickness | 0.5–6.0 mm (material?dependent) |

| Max blank size | Up to 1500 × 3000 mm (process?dependent) |

| Min hole diameter | ≈ 1.0 × material thickness (laser); punch tooling dependent |

| Bending length | Up to 2500 mm+ (tooling dependent) |

| Tolerances | Cutting ±0.1–0.2 mm typical; bending angle ±0.5–1.0°; formed dims per DFM |

| Welding | TIG / MIG / Spot; cosmetic grind & polish available |

| Finishes | Powder coat, liquid paint, anodize (Al), plating, brushing, passivation |

| Lead time | Prototypes as fast as days; batch lead time per quantity & finish |

Materials Overview

- Carbon steel: strong, economical; excellent for powder coating.

- Stainless steel (304/316): corrosion resistance; clean laser edges; food/medical/harsh environments.

- Aluminum (5052/6061): lightweight; good for anodize and complex bends; watch minimum inside radius.

- Copper/Brass: conductivity, EMI/RFI shielding; suitable for precision electronic enclosures.

Design for Manufacturability — Quick Tips

- Keep hole?to?edge ≥ 1.5× thickness and hole?to?bend ≥ 2× thickness.

- Use consistent bend radii where possible; specify critical dimensions clearly.

- For powder coat, add masking notes and adjust tolerances for film thickness.

- Use self?clinching hardware (PEM) for repeatable assembly in thin sheets.

Applications & Industries

Automotive brackets and guards; industrial machine enclosures; server racks; consumer electronics housings; test fixtures; retail POS; HVAC panels; lighting frames and more.

FAQs

- 1. What’s the difference between laser cutting and CNC punching?

- Laser excels at complex profiles and edge quality across many materials. CNC punching is ideal for thin sheets with high hole counts and special formed features, offering speed and cost benefits in larger batches.

- 2. What tolerances can Mastars hold for 1–3 mm aluminum sheets?

- Typical cutting ±0.1–0.2 mm, bending angle ±0.5–1.0°. Final capability depends on geometry and finish; we confirm via DFM.

- 3. How do I choose between powder coating and liquid paint?

- Powder coat is durable, eco?friendly and cost?effective for most parts. Liquid paint suits oversized parts or special textures; both support wide color options.

- 4. What’s the typical lead time?

- Prototypes can be produced rapidly; production lead time depends on quantity, material and finish. Share your files for a schedule recommendation.

- 5. What inspection is included before shipping?

- 100% visual check, critical dimensions per drawing, and inspection data on request.

Get an Instant Quote

Ready to move from prototype to production? Upload your files for a fast DFM review and a firm quote. Low MOQs supported, with integrated machining, molding, and finishing for one?stop delivery.