Mastars specializes in the design and manufacture of automotive interior and exterior trim and home appliance panels, providing parts design, structural design, mold manufacturing, and injection molded parts for automotive interior and exterior trim.

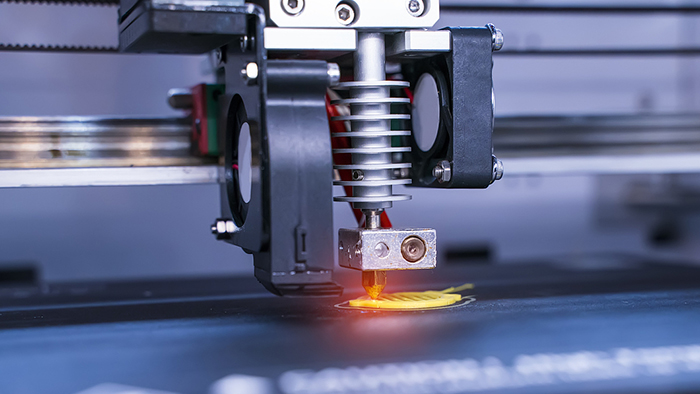

Typically we understand injection molding technology to include the three steps of pellet addition (usually a mix of resin and colorant) - extrusion in the injection molding machine - and setting and release in the mold

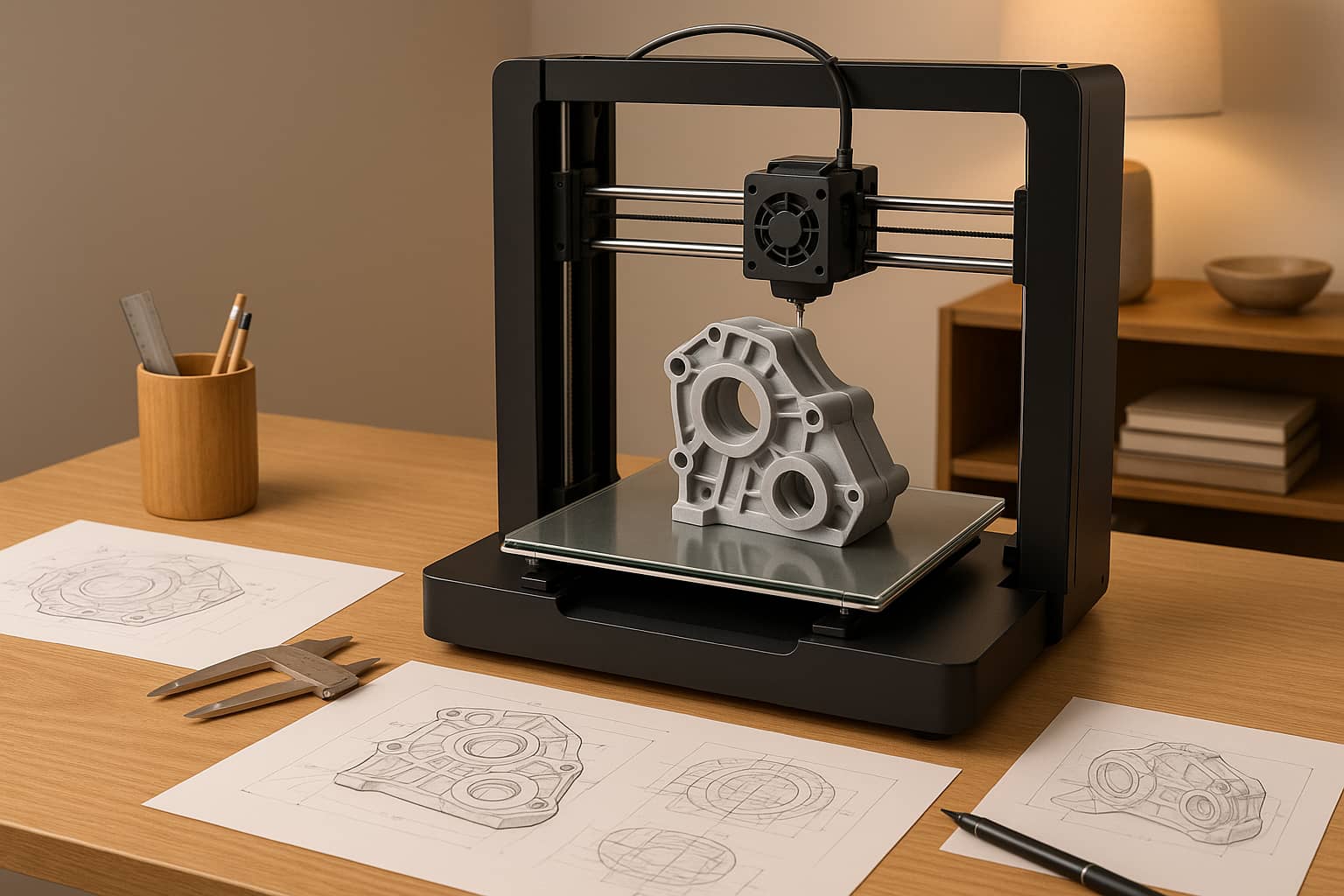

The usual

3D printing process (FDM technology) is significantly different from injection molding in the following two aspects

1) The material used is extruded modified wire with secondary processing of pellets.

2) The extruded resin melt is controlled by computer like a cake laminating process, and then the plastic is naturally cooled and molded.

And pellet

3D printing, as the name suggests, uses plastic particles directly for printing, and with that comes a significant difference in technical details from traditional FDM technology. However, the main features of FDM technology and pellet 3D printing technology are similar, such as the feeding systems are both extruded and the molding technology is both melt stacking.

Granular 3D printing is not as simple as just turning wire into pellets; this technology has features that allow for better cost reduction and greater potential for production-level applications. At present, the main focus of granular 3D printing direction in the construction, large size mold direction, such as wind power industry, construction machinery industry, automotive industry, aviation industry, etc..