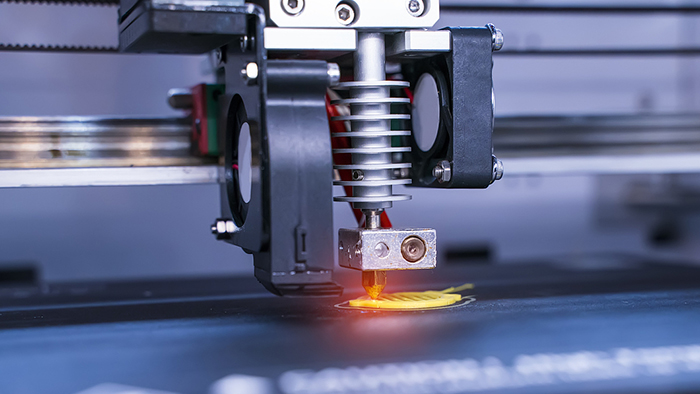

Pressure die casting is a metal manufacturing process that involves injecting molten metal into steel moulds under high pressure. It’s widely used in industries like automotive, medical, and electronics to create complex, precise parts. Simulation tools have transformed this process, enabling engineers to predict and address potential issues before production begins.

Key benefits of simulation in mould design include:

Top simulation tools for pressure die casting include:

These tools empower manufacturers to refine designs, improve efficiency, and ensure high-quality outcomes across various industries.

Simulation tools play a crucial role in assessing the performance of die casting moulds before they go into production. Each platform comes with distinct features designed to optimise designs and address specific challenges. Here's an overview of some of the top tools in this field.

MAGMASOFT is a versatile tool designed to analyse various stages of the casting process.

ProCAST stands out for its advanced thermal and mechanical modelling capabilities.

FLOW-3D CAST focuses on fluid flow simulation, especially for complex mould geometries.

AnyCasting is tailored specifically for high-pressure die casting applications.

The table below provides a quick comparison of the features offered by these tools:

| Feature | MAGMASOFT | ProCAST | FLOW-3D CAST | AnyCasting |

|---|---|---|---|---|

| Key Focus | Mould filling and solidification | Thermal and mechanical analysis | Fluid flow in complex geometries | High-pressure die casting simulation |

| Defect Detection | Predicts potential defects | Evaluates stress and solidification issues | Highlights flow irregularities | Targets casting-specific challenges |

| Usability | Comprehensive simulation features | Advanced modelling tools | Tailored for complex flow scenarios | User-friendly interface |

Each tool brings its own strengths to the table, making the choice dependent on the specific needs of the project, the complexity of the components, and the production goals.

Effective simulation software is built on three main pillars: mould filling analysis, solidification modelling, and defect prevention. These elements work together to ensure high-quality casting outcomes.

Understanding how molten metal behaves during the filling process is critical to producing reliable castings. Here are the primary aspects of mould filling analysis:

Once the filling process is fine-tuned, the next step is solidification modelling to ensure the casting cools uniformly.

Solidification modelling focuses on predicting how the casting will cool and identifying potential problem areas. Key features include:

With solidification under control, the final step is to anticipate and mitigate defects.

Preventing defects is crucial for achieving high-quality results. Simulation software offers tools to address common issues:

For manufacturers like Mastars, these advanced simulation capabilities are indispensable. They play a key role in delivering high-quality pressure die casting solutions for industries such as automotive, medical devices, and household appliances. By leveraging these tools, manufacturers can meet the demanding standards of modern production.

Simulation plays a crucial role in creating precise, data-driven designs for pressure die casting moulds. By leveraging its capabilities, engineers can address challenges and optimise designs before physical production begins. Let’s explore how simulation is applied in practical scenarios.

Before committing to costly physical tooling, simulation software allows engineers to virtually test and validate key elements of the mould design. For example, gating dimensions can be simulated to identify filling inconsistencies or turbulence that might impact casting quality.

Similarly, cooling channel layouts are tested to ensure even solidification and effective thermal management. By evaluating cooling times and temperature distribution, engineers can optimise thermal performance without the need for excessive prototyping.

Simulation tools are invaluable for fine-tuning casting parameters, leading to better results. Engineers can adjust injection speeds to minimise turbulence and avoid premature solidification, ensuring a smoother process. Die temperature can also be optimised to maintain consistent thermal cycles, while pressure profiles are refined to ensure proper metal feeding and to prevent issues like flash formation.

By pinpointing areas that need additional pressure support, simulation helps reduce defects such as shrinkage, contributing to a more reliable and efficient process.

One of the standout benefits of simulation is the speed at which it provides feedback. Engineers can make quick adjustments to elements like gate positions, wall thickness, or cooling channel placements and immediately assess their impact on casting quality. This rapid iteration helps refine designs faster.

Additionally, simulations help optimise material usage, reducing waste and improving cost efficiency. By analysing how material is distributed across runners, overflows, and the final casting, engineers can make informed decisions to minimise excess use while maintaining product quality.

For manufacturers such as Mastars, incorporating advanced simulation tools into their pressure die casting services allows them to validate designs virtually before creating physical tooling. This approach not only enhances efficiency but also ensures high-quality outcomes. Mastars applies this methodology across industries like automotive, medical devices, and household appliances, delivering reliable and cost-effective manufacturing solutions tailored to their clients' needs.

Simulation tools are reshaping the way pressure die casting moulds are designed by providing precise defect predictions and streamlining process optimisation. With these tools, manufacturers can pinpoint potential problems and refine designs before investing in costly physical tooling.

By combining mould filling analysis, solidification modelling, and defect prediction, these technologies significantly reduce development time and costs. Engineers can quickly test and refine their designs, making data-driven decisions that improve both product quality and manufacturing efficiency. This efficient workflow has become a cornerstone for leading industry practices.

Advanced simulation technology offers a clear advantage for manufacturers aiming to produce superior pressure die casting solutions. These tools seamlessly align with integrated manufacturing strategies, focusing on efficiency, quality, and cost-effectiveness across a wide range of industrial applications.

Mastars leverages these simulation tools to deliver comprehensive pressure die casting solutions. Their approach ensures optimised mould designs that meet stringent quality requirements while remaining cost-competitive. This dedication to precision and efficiency benefits clients in industries like automotive, medical devices, and household appliances, providing tailored manufacturing solutions that meet specific needs.

As discussed, simulation plays a crucial role in design validation and process optimisation. The future of pressure die casting mould design lies in embracing these technologies to achieve more precise, efficient, and reliable manufacturing processes, ensuring consistent, high-quality results.

Simulation tools are invaluable in reducing defects in pressure die casting moulds. They help identify potential problems like porosity, shrinkage, and flow marks before production even starts. By doing so, engineers can fine-tune mould designs, filling conditions, and process parameters, leading to a more seamless and efficient casting process.

By virtually replicating the casting process, simulation software highlights areas where defects are likely to occur. This allows for targeted adjustments that not only improve quality but also cut down on expensive rework, boost production efficiency, and deliver consistently reliable results.

MAGMASOFT is tailored for refining metallurgical processes, improving the quality of castings, and boosting project efficiency. With its advanced simulation and process management tools, it helps cut costs and simplify workflows.

ProCAST stands out in its ability to predict microstructure, residual stresses, and porosity. This makes it a powerful tool for validating manufacturing processes and achieving top-notch casting results.

FLOW-3D CAST specialises in detailed simulations of fluid flow, heat transfer, and solidification. It provides precise control over process parameters, making it invaluable for tasks like rotor design and process optimisation.

On the other hand, AnyCasting is not related to casting simulations. It is a network routing technology focused on managing internet traffic and defending against DDoS attacks, with no connection to pressure die casting processes.

Solidification modelling is a key element in the pressure die casting process. It helps predict how molten metal cools and solidifies within the mould, allowing manufacturers to fine-tune energy extraction rates and manage solidification patterns. The result? Consistently high-quality castings.

This modelling technique also helps spot potential problems early in the design stage, such as porosity, uneven grain structures, or weak spots. By addressing these issues upfront, manufacturers can minimise defects and enhance the mechanical properties of the final product. The outcome is stronger, longer-lasting castings with better overall performance - making solidification modelling an essential tool for precision and reliability in the die casting industry.