Sheet metal recycling is reshaping the automotive industry. Why? It reduces waste, cuts costs, and supports energy-efficient manufacturing. Modern vehicles, built with metals like steel and aluminium, are now designed with recycling in mind, making the recovery process smoother and more efficient.

Key takeaways:

Regulations and market demand are pushing manufacturers to prioritise recycled materials. With advancements in recycling methods and OEM support, the shift towards more efficient and cost-effective manufacturing is well underway.

The world of recycling is constantly changing, and the automotive industry is seeing some exciting advancements in how sheet metal is recovered. These technologies are making the process more efficient while also addressing ongoing challenges in sustainability.

New sorting technologies like X-ray fluorescence (XRF) and infrared systems are now being used to identify metal grades and detect coatings or contaminants. XRF, in particular, is a non-destructive way to differentiate between types of steel and aluminium, ensuring the quality of materials remains intact during recycling.

Robotic dismantling systems have also become a game-changer, precisely removing components while preserving the sheet metal. Automated fluid drainage systems are being used to extract leftover oils and coolants, and eddy current separators, which rely on magnetic fields, are effectively separating ferrous from non-ferrous metals.

These advanced techniques are laying the groundwork for tackling the unique challenges posed by modern and electric vehicles.

With advancements in sorting, recycling methods are now tailored to handle the complexities of modern vehicle designs. For instance, aluminium space frames used in many newer vehicles require specialised care due to their intricate joining techniques. Thermal separation processes have been developed to break adhesive bonds without harming the underlying metal.

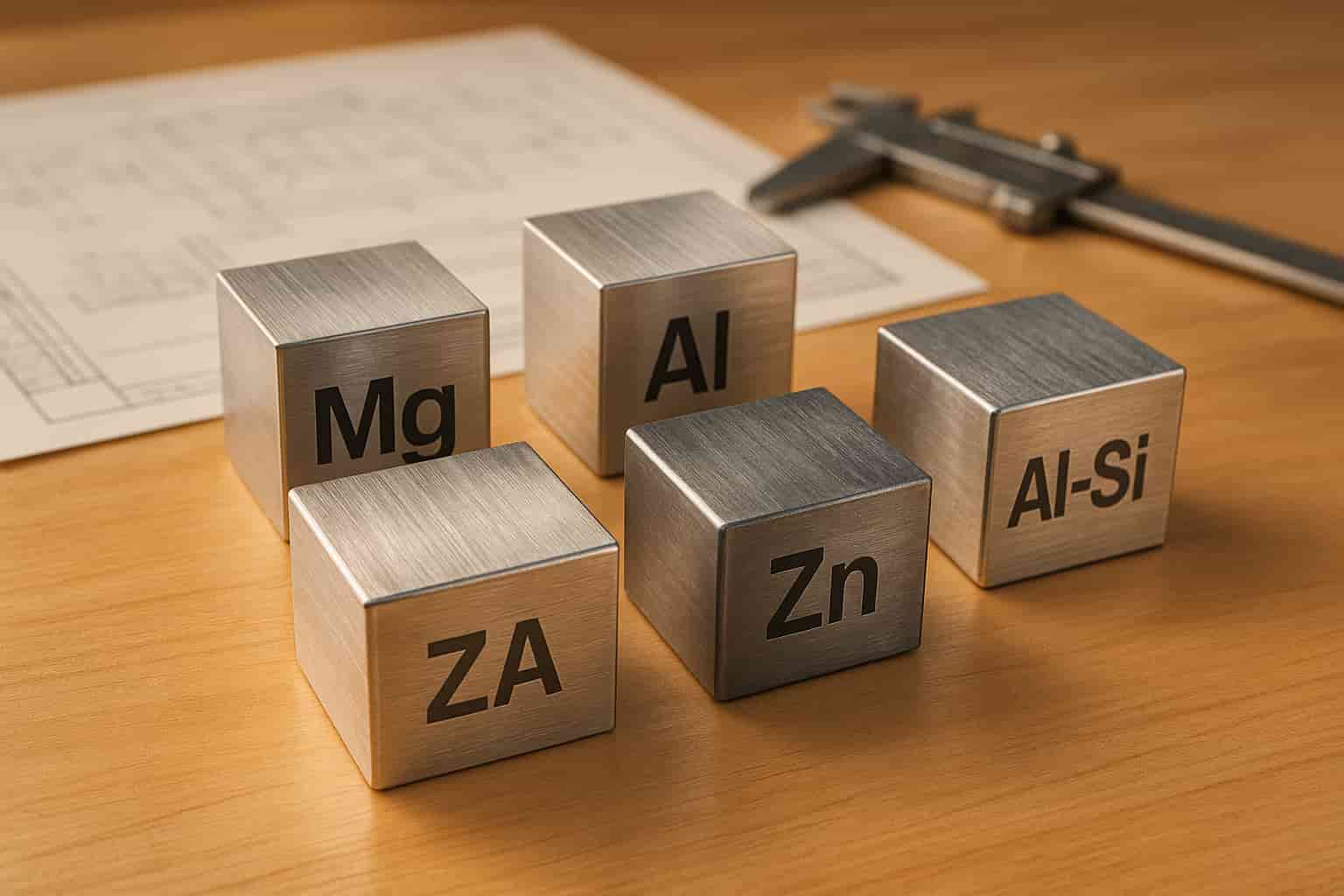

Electric vehicles (EVs) bring their own set of challenges. Robotic systems are being employed to safely remove battery packs, preventing contamination of the recycling stream. Processing innovations are also focused on preserving the structural properties of high-strength steel and recovering reactive materials like magnesium safely and effectively.

As recycling technology improves, more manufacturers are embracing closed-loop systems to boost sustainability. These systems allow recycled sheet metal to be fed directly back into production. Digital tracking tools, such as blockchain, are being used to ensure traceability throughout the recycling process. On-site recycling facilities at manufacturing plants are further streamlining operations, cutting down on turnaround times.

Artificial intelligence is also playing a role by adjusting processing parameters on the fly, making recycling workflows more efficient. Together, these advancements are shaping a future where sheet metal recycling is not only more effective but also more environmentally friendly, supporting the evolution of automotive manufacturing.

Australia's shifting regulations and growing appetite for recycled materials are encouraging automotive manufacturers to rethink how they source and produce sheet metal. With advancements in recycling technology paving the way, these regulatory shifts and market trends are laying the groundwork for a more sustainable industry.

As recycling technologies become more advanced, regulatory frameworks are adapting to support these innovations, creating a mutually reinforcing cycle of progress.

Australian policymakers are stepping up efforts to promote metal recovery and reuse. Recent initiatives focus on increasing the use of recycled materials in automotive manufacturing. At the same time, various states are introducing measures that push manufacturers to source more of their sheet metal from certified recycling facilities.

Economic patterns and industry analysis suggest that the adoption of recycled sheet metal will continue to grow. Key drivers include cost efficiencies and simplified supply chains, both of which make recycled materials an appealing choice for manufacturers.

As advancements in recycling technologies and regulatory changes reshape industries, original equipment manufacturers (OEMs) are stepping up to lead the charge in Australia's automotive sector. These manufacturers play a pivotal role in bridging the gap between cutting-edge recycling innovations and their practical application, particularly in the integration of recycled sheet metal into production processes.

For many automotive companies, the expertise required to adopt recycled materials isn’t readily available in-house. This is where OEM solutions come into play, offering the technical know-how and manufacturing capabilities needed to incorporate recycled materials seamlessly into existing workflows.

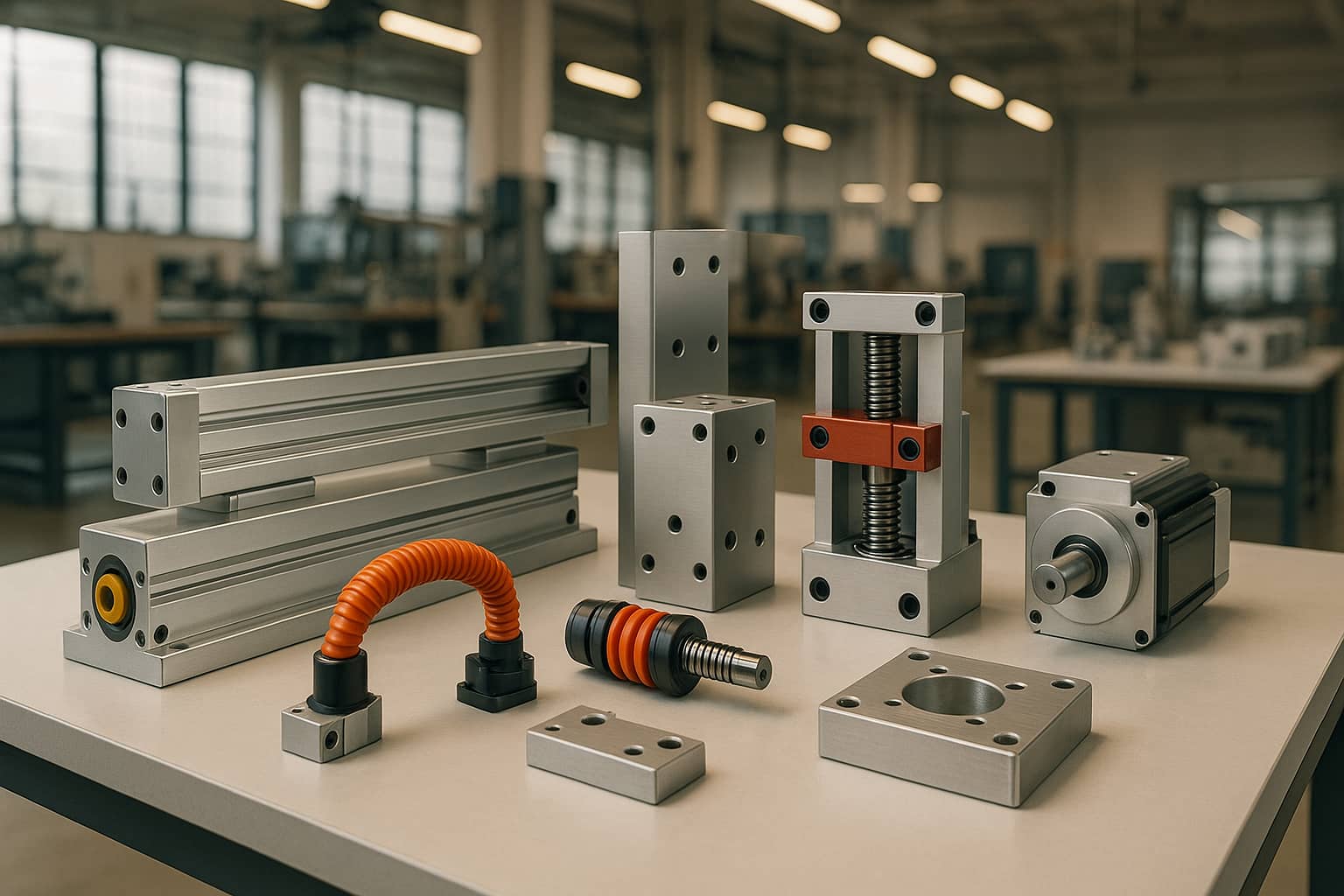

Mastars is a prime example of how OEMs are driving the shift toward sustainable manufacturing. Their sheet metal prototyping services allow manufacturers to test recycled materials before committing to full-scale production. This step is essential because recycled materials often have more variability in their properties compared to virgin materials, making early testing critical.

Beyond prototyping, Mastars provides tooling and assembly services, which are crucial for adapting production lines to handle recycled materials. Instead of juggling multiple suppliers, manufacturers can rely on Mastars' all-encompassing approach to streamline the transition, ensuring every aspect of the production line is optimised for recycled material use.

Additionally, their expertise extends to injection moulding and pressure die casting, offering a complete solution for components that combine recycled sheet metal with other materials. This capability is especially useful when creating complex assemblies, as it ensures consistency and quality across diverse manufacturing processes while minimising coordination headaches.

Innovative manufacturing technologies are transforming how recycled sheet metal is integrated into production. Mastars employs rapid CNC machining, 3D printing, and vacuum casting to quickly prototype and validate recycled materials. This agile approach reduces the need for costly tooling adjustments and accelerates the testing process.

To ensure quality, Mastars applies rigorous standards to recycled materials, leveraging their cross-sector expertise to better understand and meet performance requirements. Their use of Industry 4.0 technologies takes this further by enabling real-time monitoring of recycled materials throughout the production process. This data-driven approach allows manufacturers to fine-tune their applications, identifying the most effective uses for specific recycled materials.

Fast turnaround times, a hallmark of OEM operations, also make it easier to run iterative tests and refine processes. By providing these comprehensive solutions, OEMs like Mastars enable automotive manufacturers to adopt recycled materials without overstretching their internal resources.

Australia's automotive recycling sector is undergoing significant changes, driven by automation, technological advancements, and evolving regulations. This intersection of environmental responsibility and economic efficiency is reshaping the industry, with progress in closed-loop systems and OEM-integrated solutions setting the stage for more sustainable manufacturing practices.

Advancements in modern recycling techniques and regulatory updates are reducing contamination in recovered sheet metal, which historically impacted quality. These improvements now make it possible to produce recycled sheet metal that meets the stringent standards required for automotive applications.

The growing adoption of electric vehicles (EVs) is expected to diversify recycling streams in the coming decade. Australian manufacturers upgrading their recycling processes today are well-positioned to capitalise on the increasing demand from the EV sector, gaining a competitive edge as the market evolves.

For companies, viewing regulatory requirements as opportunities rather than obstacles can lead to significant advantages. Reduced material costs and improved sustainability credentials can enhance their market position while aligning with environmental goals.

This transformation builds on the advanced recycling techniques and regulatory frameworks previously discussed. Mastars’ integrated approach, which combines sheet metal prototyping, rapid CNC machining, and Industry 4.0 monitoring, demonstrates how recycling innovations can align seamlessly with manufacturing needs. This ensures that automotive manufacturers can utilise recycled materials without sacrificing quality or efficiency.

Achieving a thriving circular economy depends on smooth integration across all stages - advanced sorting technologies, efficient recycling processes, and innovative OEM solutions. Every part of the chain must work cohesively to produce cost-effective, high-quality recycled materials. As the industry embraces this shift, Australia's automotive recycling sector is poised for growth, balancing environmental goals with economic success.

Advanced technologies like X-ray sorting and robotic dismantling are transforming how sheet metal recycling is handled in the automotive sector. With X-ray sorting, metals can be separated with exceptional accuracy based on their elemental composition and density. This means recycled materials are of higher quality, while waste is minimised, making the entire recycling process more efficient.

On the other hand, robotic dismantling automates the process of taking vehicles apart. This not only speeds up operations but also ensures components are removed with greater precision. By reducing the need for manual labour, it streamlines recycling and boosts the recovery of valuable materials. These advancements are setting the stage for a more efficient and environmentally friendly approach to sheet metal recycling in Australia.

Electric vehicles (EVs) bring some distinct challenges to the recycling of sheet metal, largely due to the intricate design of their batteries and electronic systems. Extracting materials like lithium and other metals from these components often demands specialised techniques, which can be both labour-intensive and technically complex.

To tackle these challenges, progress is being made in battery recycling technologies that aim to recover materials more effectively while minimising environmental harm. At the same time, efforts are focused on expanding the infrastructure required to handle end-of-life EVs. This ensures that valuable materials are reclaimed efficiently and with minimal waste. As EV adoption continues to rise - especially in regions like Australia, where sustainability and forward-thinking solutions are highly valued - these advancements play a crucial role in meeting the demands of a greener future.

Closed-loop recycling systems offer notable benefits for automotive manufacturers, helping to cut down waste, lower production expenses, and preserve natural resources. By reusing materials like sheet metal and plastics, these systems contribute to a more efficient and eco-friendly production cycle - an essential step in meeting both environmental goals and regulatory demands.

The addition of digital tracking takes these systems to the next level. With precise monitoring of materials throughout their lifecycle, manufacturers can ensure resources are reused and recycled effectively. This approach not only boosts transparency but also promotes accountability across the supply chain. By embracing digital tools, automotive companies can better manage resources and reinforce their dedication to sustainable practices.