Choosing the right material for CNC machining is crucial for achieving project success. The material impacts performance, durability, cost, and manufacturability. Here's a quick guide to help you decide:

When selecting materials for CNC machining, understanding their key properties is essential. These properties directly influence machining performance and the functionality of the final product. Let’s break down the most critical factors to consider.

Thermal properties are a major consideration in CNC machining, especially given the heat generated during cutting. Thermal conductivity determines how efficiently a material transfers heat. For example, aluminium alloys excel in dissipating heat quickly, which helps minimise thermal damage and ensures better machining efficiency.

Equally important is thermal expansion, which measures how much a material expands when heated. This is critical for precision components, as excessive expansion can compromise dimensional accuracy. Plastics, for instance, tend to expand more than metals, requiring careful temperature management during machining to maintain tight tolerances.

Heat resistance is another key factor, particularly for industries like aerospace and automotive where components often face high operating temperatures. Materials such as stainless steel or high-temperature plastics like PEEK maintain their properties under extreme heat, making them ideal for these demanding environments.

It's also worth noting that the friction generated during machining can lead to significant heat buildup. Materials unable to handle this heat may warp, crack, or experience surface degradation, which can increase production costs due to rejected parts.

Mechanical properties reveal how materials respond to forces and stresses, which directly affects both machinability and the performance of the final component. Strength is a broad category that includes tensile strength (resistance to pulling), compressive strength (resistance to crushing), and yield strength (the point where permanent deformation begins).

Hardness plays a big role in how easily a material can be machined. Softer materials like aluminium are easier to cut and yield smooth finishes, while harder materials like hardened steel require specialised tooling and slower cutting speeds. However, harder materials often provide better wear resistance, which may be critical for the part's intended use.

Ductility measures a material’s ability to deform without breaking. Ductile materials can absorb shocks and bend under pressure rather than fracturing, making them ideal for applications involving dynamic loads or potential impacts.

Toughness, a combination of strength and ductility, indicates how much energy a material can absorb before failing. This is particularly important for components exposed to shock loads or vibrations during operation.

Keep in mind that these properties often involve trade-offs. For instance, increasing hardness usually reduces ductility. Choosing the right material means finding the right balance for your specific application.

Environmental conditions and chemical exposure are critical considerations for both machining and long-term performance. Corrosion resistance is especially vital in areas like Australia’s coastal regions, where salt air can quickly degrade materials. Stainless steel and certain aluminium alloys offer excellent protection against corrosion, ensuring durability in harsh environments.

Chemical resistance is equally important for applications in industries like medical and food processing. Materials must withstand exposure to cleaning agents, acids, or solvents without degrading or contaminating their surroundings. For example, medical components often require biocompatible materials that can endure sterilisation processes.

Material density also comes into play, especially for industries like aerospace and automotive, where reducing weight can boost performance and improve fuel efficiency. Lightweight materials that maintain strength are often prioritised in these applications.

Other environmental factors include UV tolerance, which is critical for outdoor applications exposed to Australia’s intense sunlight, and flame retardance, essential for aerospace or medical components where fire safety is a concern. Additionally, some materials release harmful byproducts during machining - for instance, PVC fumes - necessitating proper safety measures and ventilation systems.

Australian industrial environments often face extreme temperature conditions, from the heat of mining operations to the cold of refrigeration systems. Materials must retain their properties across these temperature ranges and withstand thermal cycling, where repeated heating and cooling can lead to fatigue and eventual failure.

When it comes to CNC machining, selecting the right material can make all the difference. Each material brings its own set of thermal, mechanical, and machining properties to the table. Let’s explore the characteristics of some commonly used metals and engineering plastics to help you make informed decisions.

Aluminium alloys are widely used in CNC machining for their ease of cutting and versatility. They produce clean cuts with minimal tool wear, enabling high cutting speeds and smooth surface finishes. Among these, 6061-T6 aluminium strikes a great balance between strength and machinability, making it a go-to for automotive parts, electronic enclosures, and general-purpose engineering. Its corrosion resistance adds value for marine applications, especially when anodised for extra durability.

Mild steel is a budget-friendly option known for its strength, making it ideal for structural and heavy-duty uses. However, it requires slower machining speeds and generates more heat compared to aluminium. Additionally, it tends to work-harden, so maintaining consistent cutting parameters is key to achieving precision.

Stainless steel stands out for its excellent corrosion resistance and ability to perform under extreme temperatures. Grade 316 stainless steel is particularly suited for marine settings and food processing. However, its lower thermal conductivity and work-hardening nature make it more challenging to machine, requiring sharp tools and effective coolant use.

Brass is favoured for its ability to produce smooth, burr-free finishes. Its antimicrobial properties make it a top choice for medical applications and plumbing. While its softer nature allows for intricate detailing, proper support during machining is necessary to avoid vibration or chatter.

Copper excels in electrical and thermal conductivity, making it perfect for wiring and heat sink applications. While it machines well, it has a tendency to stick to cutting tools, so careful selection of tool coatings and parameters is essential. Its ductility also makes it suitable for components requiring flexibility.

Titanium offers a high strength-to-weight ratio and is biocompatible, making it indispensable in aerospace and medical industries. Grade 5 titanium (Ti-6Al-4V) is a common choice, though its low thermal conductivity and reactivity with cutting tools make it a challenge to machine. Specialised tools and expertise are often required.

Each metal comes with its own set of advantages and challenges. Depending on your project needs, you may also want to consider engineering plastics for their unique properties.

While metals dominate in strength and heat resistance, engineering plastics offer lightweight solutions and design flexibility.

ABS (Acrylonitrile Butadiene Styrene) is a versatile plastic that machines cleanly without issues like melting or chip welding. It’s a popular choice for prototypes, jigs, and fixtures. With its impact resistance and dimensional stability, ABS works well in automotive interiors and consumer electronics.

Nylon (Polyamide) is prized for its wear resistance and low friction, making it ideal for gears, bearings, and sliding parts. However, it absorbs moisture, which can affect its dimensions. Proper storage and pre-drying may be necessary for maintaining precision.

Polycarbonate combines impact resistance with optical clarity, making it suitable for applications requiring transparency, such as automotive and aerospace components. While it machines well, stress cracking can occur if not handled carefully.

PEEK (Polyetheretherketone) is a high-performance plastic that retains its properties at temperatures up to 250°C. It’s resistant to chemicals and sterilisation, making it a favourite for medical devices and aerospace parts. Although expensive, its durability and biocompatibility often justify the cost.

Delrin (POM - Polyoxymethylene) is known for its excellent machinability, producing smooth finishes and holding tight tolerances. It’s commonly used for precision components like gears and bushings. However, machining Delrin can release formaldehyde, so proper ventilation is a must.

Here’s a quick comparison of the key attributes of these materials to help you evaluate their suitability for your project:

| Material | Machinability | Cost | Strength | Corrosion Resistance | Thermal Stability | Typical Applications |

|---|---|---|---|---|---|---|

| Aluminium 6061 | Excellent | Low | Moderate | Good | Moderate | Electronics, automotive, engineering |

| Mild Steel | Good | Very Low | High | Poor | Good | Structural components, brackets |

| Stainless Steel 316 | Moderate | Moderate | High | Excellent | Excellent | Marine, food processing, medical |

| Brass | Excellent | Moderate | Moderate | Good | Moderate | Plumbing, electrical, decorative |

| Titanium Grade 5 | Difficult | Very High | Excellent | Excellent | Excellent | Aerospace, medical implants |

| ABS | Excellent | Low | Low-Moderate | Fair | Poor | Prototypes, housings, fixtures |

| Nylon 6 | Good | Low | Moderate | Good | Moderate | Gears, bearings, mechanical parts |

| PEEK | Good | Very High | High | Excellent | Excellent | Medical devices, aerospace |

| Delrin | Excellent | Moderate | Moderate | Good | Good | Precision components, gears |

Choosing between metals and plastics ultimately depends on the performance needs and operating environment of your project. Metals often shine in strength and durability, while plastics provide lightweight, corrosion-resistant options that can be easier to machine. By weighing these factors, you can select the material that best aligns with your application and budget.

Choosing the right material for CNC machining becomes much simpler when you follow a clear, structured process. By carefully assessing your needs, you can narrow down your options and make decisions that balance performance and budget. Building on the thermal and mechanical properties discussed earlier, here’s how to approach material selection step by step.

Start by identifying the specific functions and operating conditions of your component. The environment in which it will operate often has the biggest influence on material choice.

Load and stress analysis is a critical starting point. Think about both static loads (constant forces) and dynamic loads (changing or cyclic forces). For example, a bracket holding a 50kg motor faces very different demands compared to a gear experiencing repetitive stress. Be sure to document the maximum loads and apply a safety factor (typically between 1.5 and 4, depending on how critical the application is).

Other factors to consider include the operational temperature range, exposure to elements like corrosion, UV, or chemicals, and the required dimensional tolerances. Materials can behave differently under temperature cycling, which may lead to fatigue over time.

Additionally, some materials are naturally easier to machine to precise tolerances. For instance, Delrin is known for its ability to achieve tight dimensions with minimal finishing, while softer materials like brass may need extra processing to meet the same standards.

Once you’ve outlined your requirements, prioritise the criteria that will guide your material selection. This helps you weigh competing needs effectively.

Assign consistent weights to each criterion to maintain objectivity throughout your evaluation.

Material properties are important, but practical considerations often play an even bigger role in project success.

A decision matrix is a practical tool for comparing materials and identifying the best overall choice. It’s especially useful when multiple stakeholders need to understand or agree on the selection process.

Set up your matrix by listing materials as columns and criteria as rows. Score each material against each criterion using a consistent scale, then multiply the scores by their assigned weights. The material with the highest total score usually represents the best balance of requirements.

To ensure your decision holds up, perform a sensitivity analysis. Adjust the weightings slightly to see how the rankings change. If small adjustments significantly alter the outcome, you may need to re-evaluate your criteria or gather more data.

Don’t forget about risk assessment. What if your top choice becomes unavailable or fails under unexpected conditions? Documenting a second choice can save time and prevent delays if circumstances change.

Finally, keep thorough records of your decision-making process. This documentation can serve as a reference for future projects with similar requirements and help identify areas for improvement. Whether your project is straightforward or highly complex, the decision matrix approach allows you to match the depth of your analysis to the level of risk and complexity involved.

Different industries have unique material needs, influenced by their specific applications and regulatory standards. In Australia, manufacturing must also align with local standards, adding complexity to material selection.

Materials used in automotive and aerospace industries need to handle extreme conditions while keeping weight to a minimum. The strength-to-weight ratio is a critical factor because even small weight reductions can improve fuel efficiency and performance.

Aluminium alloys like 6061-T6 and 7075-T6 are popular choices. They offer excellent strength-to-weight ratios and can handle temperatures ranging from –40°C to 150°C, making them suitable for engine and structural components. For more demanding uses, titanium alloys such as Ti-6Al-4V provide enhanced performance, though at a higher cost.

Thermal stability is another key requirement, especially for components near engines or exhaust systems. Materials like Inconel 625 are often used for parts like exhaust manifolds and turbocharger housings, where temperatures can exceed 700°C.

In Australia, automotive manufacturers must adhere to Australian Design Rules (ADRs), which set strict safety and material standards. These rules often require materials with proven impact resistance and fatigue life. Aerospace applications go even further, with Civil Aviation Safety Authority (CASA) regulations demanding full traceability and certification for all materials.

The shift toward electric vehicles has introduced new challenges. For example, battery housings need materials that combine excellent thermal conductivity for heat dissipation with electrical insulation properties. Aluminium 6063 has become a popular choice due to its ability to manage heat effectively while resisting corrosion.

Medical device manufacturing has some of the strictest material requirements, with biocompatibility being a non-negotiable standard. Materials must meet ISO 10993 certification for biological safety.

Stainless steel grades 316L and 316LVM are widely used in medical devices. These materials are highly resistant to corrosion from bodily fluids and can endure repeated sterilisation cycles. The vacuum melting process in 316LVM further reduces impurities, making it suitable for implantable devices where long-term compatibility with the human body is essential.

Titanium alloys, especially Ti-6Al-4V ELI (Extra Low Interstitial), are often used for orthopaedic implants. They offer excellent biocompatibility, integrate well with bone, and have an elasticity similar to human bone, reducing the risk of implant failure.

Manufacturers in Australia must meet Therapeutic Goods Administration (TGA) guidelines, which require rigorous testing for material suitability. This includes tests for cytotoxicity, sensitisation, and irritation for materials that come into contact with human tissue. Surface finishes must also meet strict sterility standards.

Beyond corrosion from bodily fluids, materials must withstand cleaning agents and sterilisation processes. Stainless steel components often undergo passivation treatments to enhance their corrosion resistance and remove surface contaminants.

In this sector, materials need to balance aesthetics, affordability, and performance. Smooth surfaces that allow for finishing treatments like anodising or powder coating are often required.

Cost-efficiency is a major driver for material choices. While aerospace applications can justify expensive materials, household products must deliver quality at an affordable price. Aluminium 6061 is a popular option due to its good machinability, corrosion resistance, and ability to achieve attractive finishes without excessive cost.

Engineering plastics like ABS and polycarbonate are also widely used. They are lightweight, can be machined to tight tolerances, and allow for complex designs with integrated features.

Electrical properties are critical for electronics housings. Aluminium is often used for its excellent electromagnetic interference (EMI) shielding, while plastics are chosen for electrical insulation. Australian Consumer Law enforces material safety standards, requiring components to withstand normal use without degrading in ways that could pose risks. This includes UV resistance for outdoor applications, flame retardancy for electrical parts, and chemical resistance for exposure to cleaning products.

As electronic devices grow more powerful and compact, thermal management has become increasingly important. Materials with high thermal conductivity, like copper alloys, are often used for heat sinks and chassis components, despite their higher cost and machining challenges.

Sustainability is also shaping material choices. Manufacturers are increasingly opting for recyclable materials or those with a lower environmental impact, appealing to environmentally conscious consumers.

Partnering with a skilled manufacturing expert can make CNC material selection a straightforward process. Mastars offers extensive technical and manufacturing support to guide you through this critical phase, building on the material selection basics previously discussed.

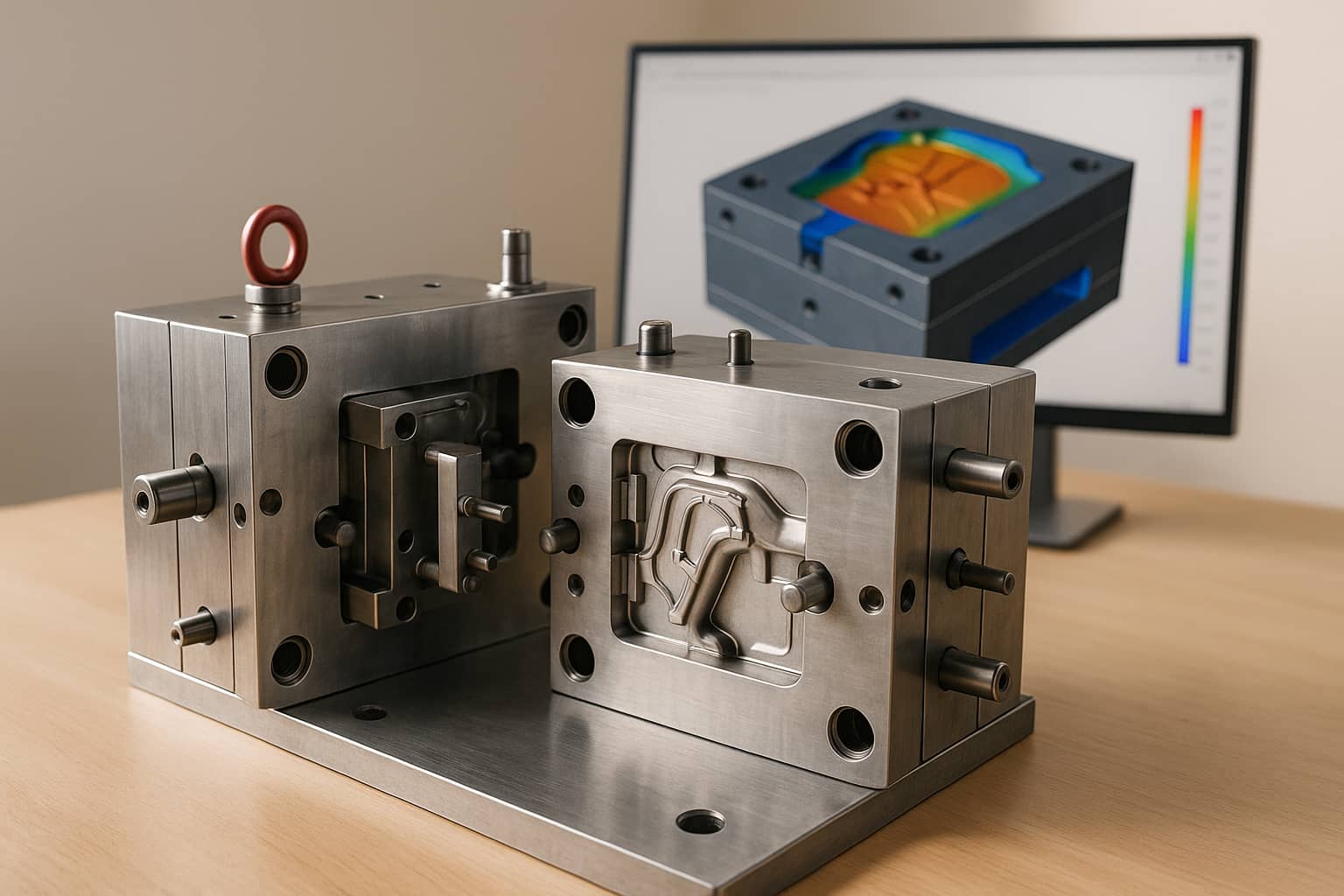

Mastars takes an integrated approach to CNC material selection, leveraging their broad manufacturing capabilities. Their rapid CNC machining services cater to both prototyping and large-scale production, allowing for early material validation.

Beyond CNC machining, Mastars' capabilities include 3D printing, vacuum casting, sheet metal prototyping, injection moulding, and pressure die casting. This comprehensive range of services helps prevent expensive material changes later in the production cycle, saving both time and resources.

Rapid prototyping is a key advantage, enabling quick material validation before moving to full-scale production. This is especially useful for Australian manufacturers who must balance compliance with local standards and cost efficiency.

Mastars’ all-in-one approach simplifies the entire process by covering machining, assembly, and finishing under one roof.

When one provider manages the entire workflow, cost optimisation becomes much more achievable. Mastars identifies opportunities to standardise materials across components, reducing inventory expenses and simplifying quality control. Their integrated process also provides a clearer understanding of how material selection affects machining time and tooling costs, leading to more precise total cost evaluations.

Quality control remains consistent throughout production. By employing advanced Industry 4.0 technologies, Mastars minimises material-related defects and ensures reliable performance across all production runs.

Having all processes in one place also improves communication and scheduling. This reduces delays that can occur when components are transferred between multiple facilities, ensuring quicker turnaround times.

Mastars' expertise extends beyond basic material properties. Their engineers understand how materials behave during machining, the surface finishes that can be achieved, and how to optimise designs for manufacturability. This expertise helps you avoid common mistakes that might arise when material selection is treated as an isolated step.

Mastars aligns their material selection process with Australia’s strict industry standards, catering to sectors like automotive, medical, household, and electronics.

For automotive applications, they recommend materials that meet rigorous local safety and performance requirements. In medical device manufacturing, where material selection is especially critical, Mastars ensures compliance with regulatory and biocompatibility standards.

When it comes to household appliances and electronics, Mastars prioritises materials that meet consumer safety regulations. Their understanding of local supply chains allows them to suggest materials readily available in Australia, reducing lead times and overall production costs.

Mastars’ tailored approach ensures material recommendations align with your specific needs - whether it’s for a prototype or large-scale production. They take into account factors like production volume, budget, and performance requirements to deliver solutions that work for startups and established manufacturers alike.

Selecting the right materials for CNC machining isn’t just about picking metals or plastics off a list - it’s about balancing performance needs with practical realities. While thermal and mechanical properties are critical, the process requires a broader perspective.

Start by defining your application’s specific requirements and prioritising criteria. Material choices directly affect machining time, tooling expenses, and overall performance, so it’s essential to approach the decision thoughtfully. A decision matrix can help weigh factors like strength-to-weight ratio, temperature resistance, and machinability against budget constraints and material availability. This structured method ensures your components meet industry standards while maintaining production consistency.

For Australian manufacturers, collaborating with a knowledgeable partner like Mastars can make this process smoother. Mastars offers more than just materials - they bring expertise in rapid prototyping, CNC machining, 3D printing, and injection moulding. By involving them early in the process, you can validate designs, reduce redesign costs, and optimise material selection for both performance and cost-efficiency.

Smart material selection doesn’t just save money - it ensures reliability, reduces maintenance, and improves customer satisfaction. With a methodical approach and expert support, you’ll make well-informed decisions that set your project up for success from the initial prototype to full-scale production.

Choosing the right material for CNC machining means finding the perfect balance between strength and lightweight properties to meet your project's unique demands. Aluminium alloys, like 2024, are a go-to option thanks to their impressive strength-to-weight ratio, resistance to corrosion, and overall versatility. They're often the first choice for a wide range of industries due to their reliability and adaptability.

If your project calls for even greater performance, titanium alloys such as Ti-6Al-4V are worth considering. Known for their outstanding strength and durability, these alloys are commonly used in high-stakes industries like aerospace and medical devices, where precision and resilience are critical.

For cutting-edge applications, composite materials offer unmatched strength-to-weight ratios. These materials shine in high-precision engineering and specialised fields, delivering exceptional results where traditional metals might fall short. When selecting your material, think about factors like the operating environment, thermal tolerances, and mechanical stresses. This careful evaluation ensures your choice not only meets performance requirements but also stays within budget.

When choosing materials for CNC machining in tough environments - think high humidity or exposure to chemicals - it's important to prioritise corrosion resistance and chemical stability. Options like stainless steel, titanium, and plastics such as PEEK, PTFE, and nylon stand out because they can withstand corrosion, chemical damage, and surface wear effectively.

For dependable, long-lasting performance, materials with high dimensional stability and wear resistance are key. This ensures components remain precise and reliable, even under harsh conditions. These factors are essential when crafting parts designed to endure extreme environments.

When it comes to CNC machining, teaming up with a manufacturing specialist like Mastars can make material selection a whole lot easier. Thanks to their deep industry experience and technical know-how, Mastars helps you choose materials that offer optimal thermal and mechanical performance for your project. This means less guesswork and smoother operations.

Mastars also offers integrated OEM manufacturing solutions designed to fit your project's unique needs. They focus on selecting materials that are durable, budget-friendly, and well-suited to Australia's specific conditions. This approach not only ensures top-notch results but also saves valuable time and resources.