In today's manufacturing industry, businesses must navigate between established traditional methods and innovative additive manufacturing technologies. This comprehensive guide examines the critical differences, advantages, and optimal applications for both approaches to help you make informed production decisions.

1. Core Definitions: Additive vs. Traditional Manufacturing

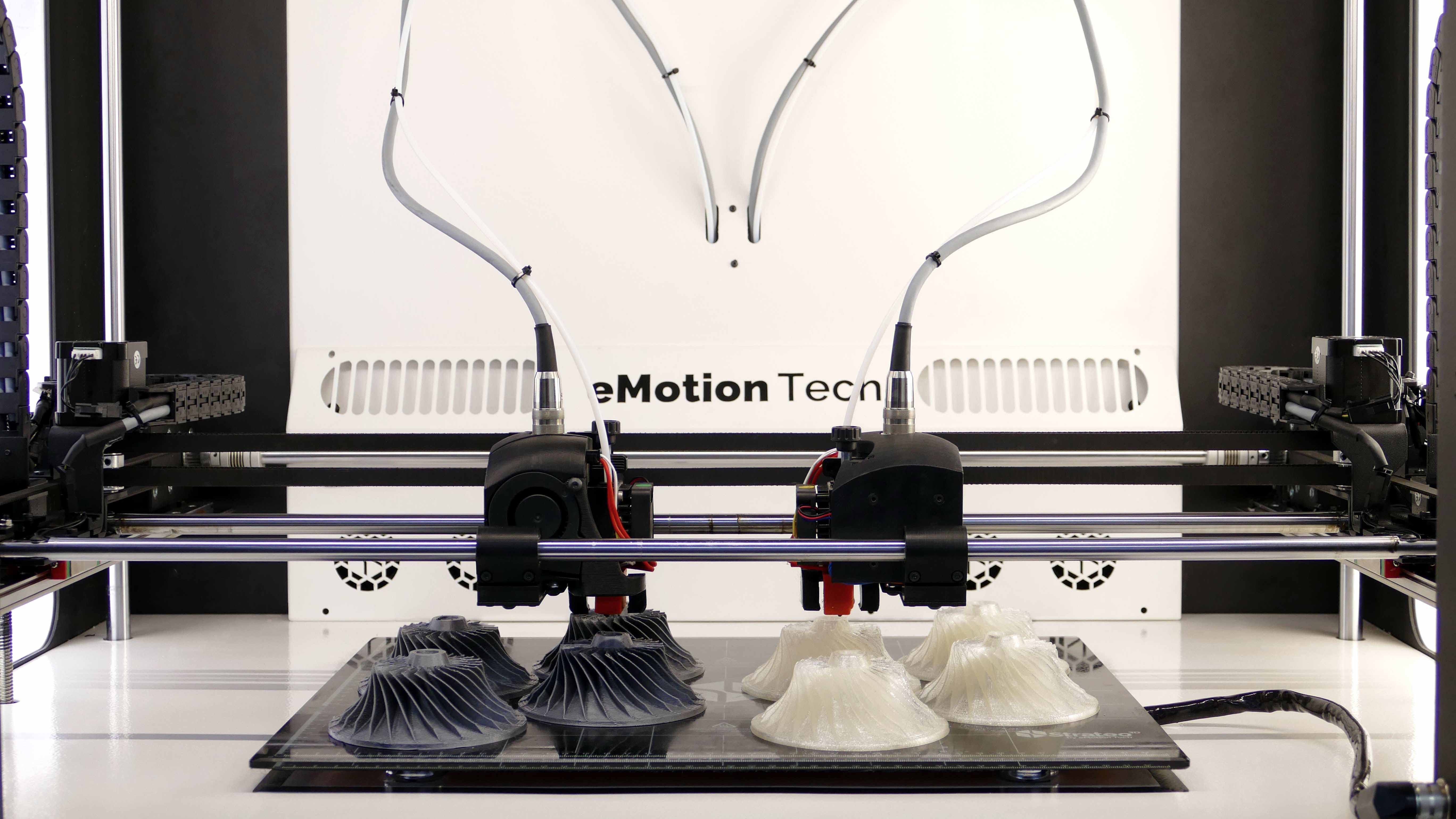

Additive Manufacturing (3D printing)

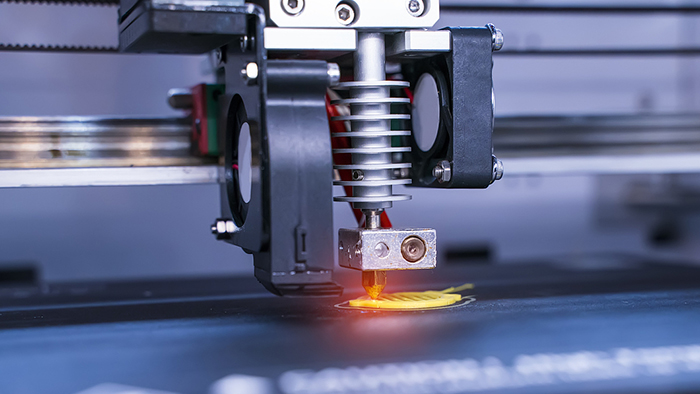

Additive manufacturing, commonly known as 3D printing, constructs objects through a layer-by-layer deposition process. Starting from a digital 3D model, material is added incrementally to build the final product, minimizing waste by using only necessary materials.

Common Additive Technologies:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- binder Jetting

Traditional Manufacturing

Traditional manufacturing utilizes subtractive, formative, or assembly processes. These methods typically start with bulk material and shape it through cutting, molding, or joining pre-fabricated components—techniques refined over centuries for mass production.

Common Traditional Methods:

- CNC Machining (milling, turning, grinding)

- Injection Molding

- Casting (sand, die, investment)

- Forming (rolling, forging, stamping)

- Welding and Assembly

2. Key Differences: A Detailed Comparison

The following table compares additive and traditional manufacturing across critical performance metrics:

| Performance Metric | Additive Manufacturing | Traditional Manufacturing |

|---|---|---|

| Cost Structure | Low upfront investment; higher per-unit material costs; consistent unit costs regardless of batch size | High initial tooling/mold costs; lower material costs; decreasing unit costs with higher volume |

| Production Speed | Rapid for prototypes/small batches (hours to days); slower for mass production | Slow setup for prototypes; extremely fast for high-volume production (thousands per hour) |

| Material Options | Limited but growing: plastics, metals, resins, ceramics, composites | Extensive: all metals, plastics, wood, glass, rubber, and composites |

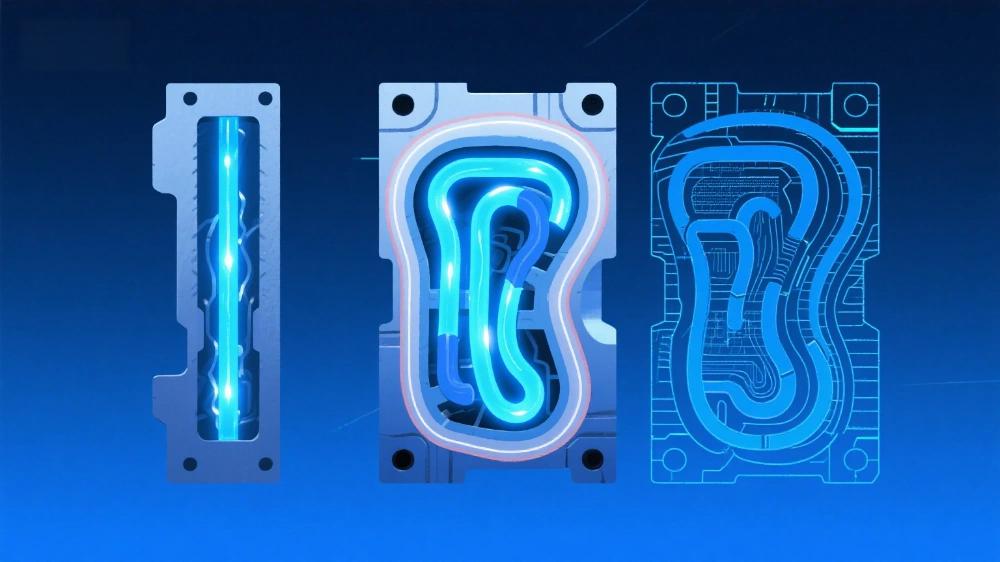

| Design Capabilities | Exceptional for complex geometries, internal structures, and organic shapes | Limited by tooling; complex designs require assembly of multiple components |

| Precision Levels | Good (±0.1mm typical); layer lines may require post-processing | Excellent (±0.001mm with CNC); consistent surface finish |

| Material Waste | Minimal (5-10%); unused material often recyclable | Significant (20-50%); especially with subtractive processes |

| Scalability | Optimal for 1-100 units; inefficient for mass production | Excellent for 1,000+ units; economies of scale apply |

| Part Strength | Variable; some technologies match traditional strength, layer adhesion can be a weakness | Consistent; uniform material properties and isotropic strength |

3. Practical Use Cases

Optimal Applications for Additive Manufacturing

- Rapid Prototyping: Functional prototypes in days rather than weeks

- Custom Components: Personalized medical implants, bespoke tools

- Complex Geometries: Lightweight aerospace parts with internal lattices

- Low-Volume Production: Specialized industrial parts, limited-edition products

- On-Demand Manufacturing: Spare parts for legacy equipment, emergency replacements

Optimal Applications for Traditional Manufacturing

- Mass-Produced Consumer Goods: Plastic toys, packaging, electronics enclosures

- High-Precision Components: Engine parts, medical instruments, aerospace hardware

- Large-Scale Production: Automotive components, construction materials

- Cost-Sensitive Items: Disposable products, high-volume standard parts

- Specialized Materials: Wood products, glass components, rubber parts

4. Future Trends in Manufacturing

The global additive manufacturing market is projected to reach $80 billion by 2030, but traditional methods will remain vital. The industry is moving toward hybrid manufacturing—combining the strengths of both approaches:

- 3D printed cores with traditionally manufactured outer shells

- CNC machined bases with 3D printed complex features

- Additively manufactured tooling for traditional production processes

Advancements in materials science and machine capabilities will continue to expand additive manufacturing's applications while traditional methods focus on efficiency improvements and sustainability.

5. Conclusion & Recommendations

Additive and traditional manufacturing are complementary technologies rather than competitors. The optimal choice depends on your specific needs:

- Choose additive manufacturing for complex designs, small batches, prototypes, or custom parts

- Choose traditional manufacturing for high-volume production, simple geometries, and cost-sensitive projects

- Consider hybrid approaches to leverage the strengths of both methodologies

By strategically implementing the right manufacturing method for each application, businesses can optimize production efficiency, reduce costs, and accelerate time-to-market for new products.