Scaling the production of custom implants in Australia is complex but achievable with the right strategies. The increasing demand for patient-specific implants, driven by an ageing population and advanced surgical techniques, presents both opportunities and challenges for manufacturers.

Key Challenges:

Solutions:

Scaling the production of custom implants comes with a unique set of hurdles that traditional manufacturing methods often fail to overcome. Unlike mass-produced medical devices, custom implants require individualised attention at every stage. This creates potential bottlenecks that can disrupt even the most carefully planned scaling strategies.

The cost of scaling custom implant production can be a major hurdle for manufacturers. Biocompatible materials like titanium alloys and medical-grade polymers are not only expensive but also add complexity to the production process. Customised designs, which are inherently one-off, further drive up costs.

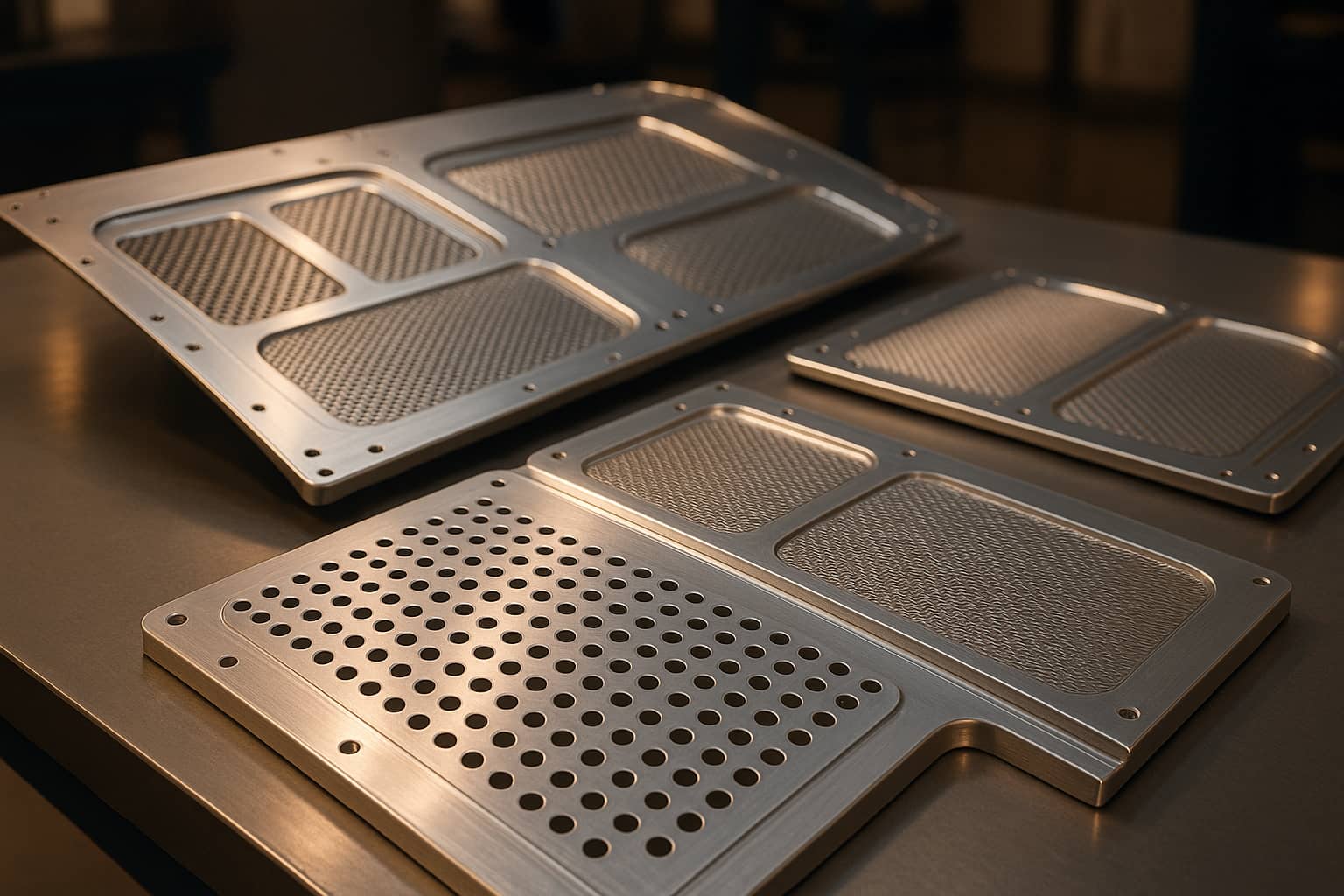

On top of that, advanced equipment such as high-precision CNC machines and industrial-grade 3D printers demands a hefty initial investment. Skilled technicians, essential for working with these materials, command high wages in Australia's competitive job market.

Mastars tackles these cost challenges by spreading expenses across multiple projects. By leveraging economies of scale through our diverse client base, we make advanced CNC machining and 3D printing technologies accessible to Australian clients. This approach allows companies to benefit from premium manufacturing capabilities without shouldering the full financial burden, offering a practical solution to what might otherwise be prohibitive costs.

Australia's Therapeutic Goods Administration (TGA) enforces strict standards for medical devices, and custom implants face even more rigorous scrutiny. Each implant design must prove its biocompatibility, mechanical reliability, and manufacturing consistency - requirements that grow increasingly complex as production scales.

Achieving and maintaining ISO 13485 certification adds another layer of difficulty. This certification demands the implementation of comprehensive quality management systems that oversee every detail of the manufacturing process. For custom implants, this includes maintaining detailed records for each device, which can become overwhelming as production volumes increase.

Every step - material sourcing, manufacturing, and quality checks - must be meticulously documented and linked to individual implants, ensuring full traceability. This level of detail adds significant complexity to scaling up production while maintaining compliance.

Mastars ensures full TGA compliance and holds ISO 13485 certification, streamlining the documentation process without compromising on regulatory standards. Our quality management systems handle the administrative load, allowing manufacturers to focus on production while maintaining full regulatory traceability for every implant.

Custom implants require an extraordinary level of anatomical precision that mass-produced devices simply cannot match. Each implant design begins with a detailed analysis of patient-specific anatomy, often derived from CT scans or MRI data. Transforming this imaging data into a manufacturable design demands sophisticated software and highly skilled engineering.

The geometric complexity of custom implants poses additional manufacturing challenges. These implants often feature intricate internal structures, variable wall thicknesses, and complex surface textures that push the limits of traditional manufacturing methods. Even advanced 3D printing technologies must balance the need for fine surface finishes with the structural strength required for medical applications.

Consistency in precision demands rigorous process control and continuous monitoring. Moreover, validating the fit of each custom device is a significant challenge. Unlike standard implants, custom devices often require individual validation through methods like physical model testing, digital simulations, or specialised protocols - all of which must scale with production.

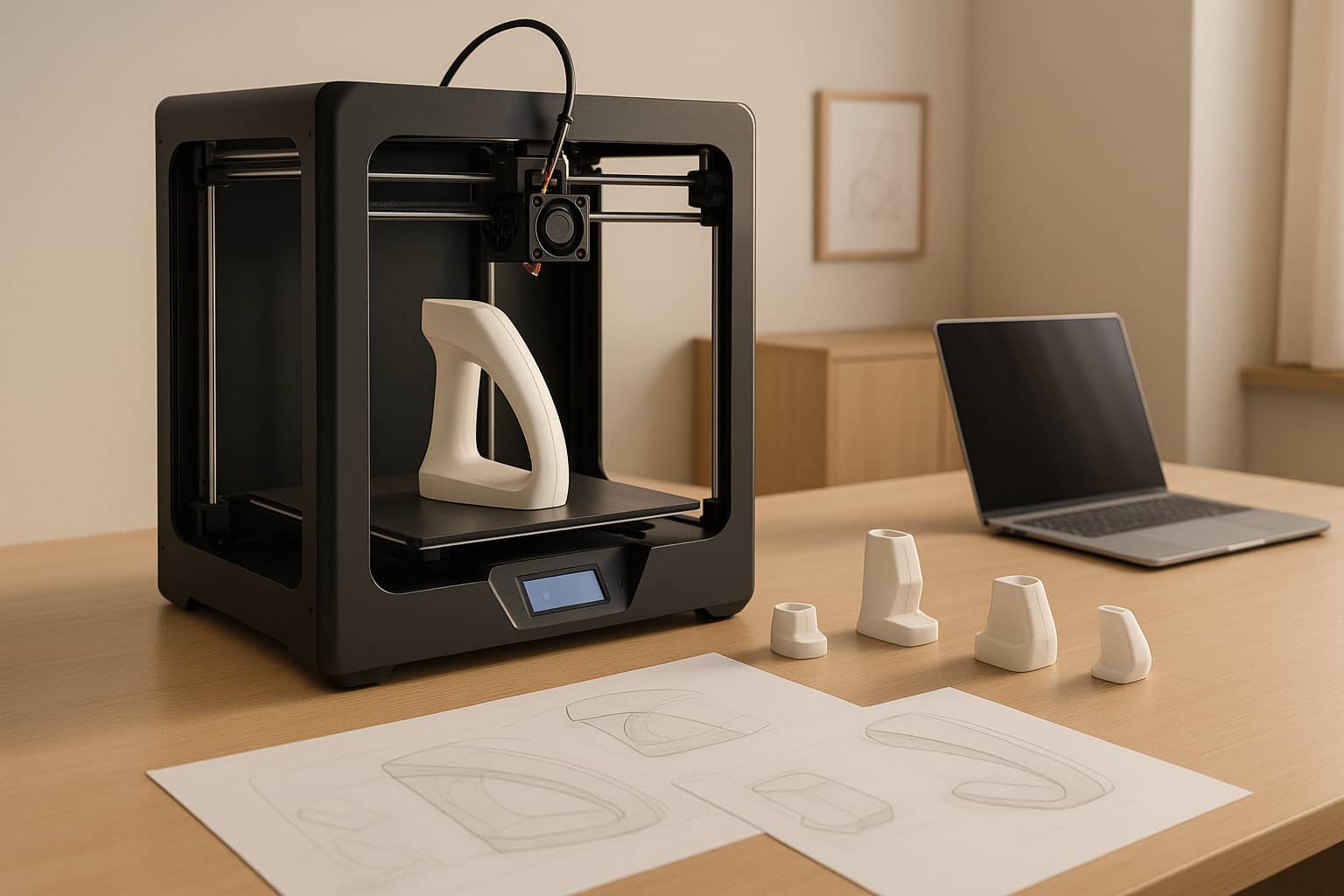

Mastars addresses these design challenges through digital modelling and rapid prototyping. Our engineering team works closely with medical imaging data to optimise designs using advanced CAD software, ensuring both anatomical accuracy and manufacturing efficiency. With integrated prototyping services, we can quickly validate designs before moving to full-scale production, guaranteeing that every implant meets exacting standards for precision and performance.

These challenges highlight the complexities of scaling custom implant production and set the stage for exploring scalable and cost-effective solutions in the following section.

Producing implants at scale requires cutting-edge technology and efficient processes. Modern advancements not only help keep costs in check but also uphold the precision and quality essential for medical applications.

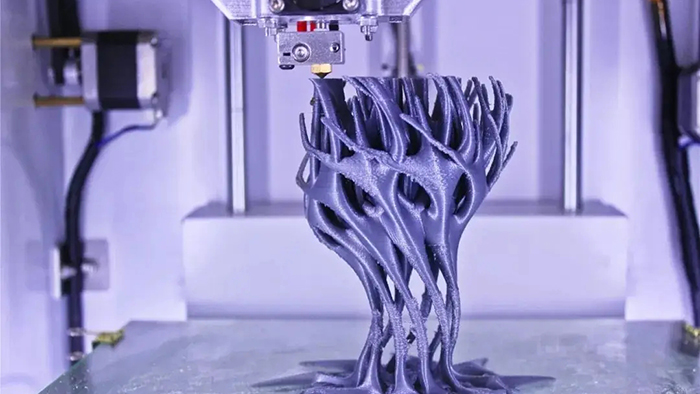

Mastars uses advanced 3D printing and digital workflows to improve implant precision while keeping costs manageable. Unlike traditional machining, 3D printing builds implants layer by layer, significantly reducing material waste. This technique also allows for the creation of intricate designs that would be challenging - or even impossible - with conventional methods.

By importing CT or MRI data directly into CAD software, highly accurate, patient-specific designs can be created without the need for multiple handoffs, reducing the risk of errors. For Australian manufacturers, this process is particularly advantageous when working with costly biocompatible materials like titanium alloys, as it minimises waste and maximises efficiency.

Mastars combines cutting-edge metal 3D printing with traditional CNC machining to strike the perfect balance between cost and quality. Our digital workflows integrate seamlessly with medical imaging data, enabling quick design iterations and thorough validation. This approach has proven invaluable for Australian medical device companies aiming to shorten development timelines while maintaining strict quality standards.

Hybrid manufacturing techniques further enhance this process. By pairing the flexibility of 3D printing with the precision of CNC finishing, manufacturers can produce implants in a near-final shape and then refine critical surfaces to meet exact specifications. This combination ensures a balance of complexity, precision, and quality.

Through these digital integrations, manufacturers can adopt end-to-end service models, compressing development timelines and streamlining the entire production process.

Bringing prototyping, testing, and production under one roof addresses many of the challenges associated with traditional implant development. This integrated approach allows for tighter quality control, shorter lead times, and fewer communication breakdowns.

Rapid iteration is key to reducing the time from design to prototype, which is essential for obtaining timely clinical feedback. When multiple vendors are involved, inconsistencies and delays often arise. However, working with a single manufacturing partner ensures consistent processes and material quality throughout.

Mastars offers fully integrated prototyping and manufacturing services, simplifying the custom implant development process for Australian clients. This streamlined approach is especially helpful for smaller medical device companies that might lack the resources to manage complex supply chains. By handling everything from initial design to production-ready implants, we eliminate the complications of coordinating multiple vendors.

This consolidation also enhances quality consistency. Insights gained during prototyping directly inform the production phase, reducing the risk of issues during full-scale manufacturing. Additionally, fixed-price models covering the entire process - from concept to delivery - help minimise financial uncertainties, giving clients a clearer picture of costs.

Maintaining high standards throughout production is just as important as rapid prototyping.

Modern quality assurance relies on real-time monitoring to catch and address deviations early. Today’s manufacturing equipment continuously tracks critical parameters, allowing potential issues to be identified before they result in defective parts. This proactive approach is vital for custom implants, where each piece plays a critical role in patient care.

Digital quality documentation enhances traceability by linking every manufacturing parameter to each implant. Automated systems ensure comprehensive records with minimal manual effort, which is crucial for meeting strict regulatory standards like those enforced by the TGA in Australia.

Predictive maintenance also improves production reliability. By using Industry 4.0 sensors to monitor machine performance, maintenance can be scheduled based on actual data, reducing downtime and keeping production schedules on track. This ensures that critical implant deliveries remain uninterrupted.

Mastars employs Industry 4.0 technologies, including real-time process monitoring and automated quality documentation. By capturing key parameters - such as temperature, pressure, and dimensional accuracy - our systems ensure that every implant meets the highest standards while maintaining full traceability for regulatory compliance.

In addition, modern statistical process control enables manufacturers to analyse entire production datasets rather than relying on periodic sampling. This continuous monitoring helps identify trends and supports ongoing process improvements. Automated inspection systems, such as laser scanning and coordinate measuring machines, ensure that even the most complex implant designs are produced with precision and consistency.

These advanced methods provide Australian clients with scalable, reliable production solutions tailored to their needs, ensuring both quality and cost efficiency.

Modern manufacturing methods offer Australian businesses the potential for significant savings over time, especially as market demands shift and production volumes grow. These savings pave the way for scalable solutions that address the unique challenges of Australia's healthcare sector.

As highlighted by Mastars' integrated manufacturing platforms, cost efficiency and scalability often go hand in hand. While traditional manufacturing might appear affordable for smaller production runs, hidden costs tend to rise as volumes increase. For example, conventional machining often requires frequent tooling updates for custom designs, which drives up setup costs. Additionally, subtractive manufacturing methods waste expensive materials like titanium alloys, common in biocompatible applications.

Modern manufacturing approaches, however, bring a range of cost-saving benefits. Improved material utilisation significantly reduces waste, while automation and digital workflows cut down on labour costs and improve inventory management. Real-time monitoring systems further enhance quality control by quickly identifying defects, reducing the risk of rework or costly recalls. Together, these advancements lower production costs and improve overall efficiency.

Mastars has worked with Australian medical device companies to implement these solutions, enabling them to streamline production and achieve substantial savings. These benefits are especially noticeable at higher production volumes, where cost efficiencies are amplified. By combining cost reductions with reliable production processes, clients can remain competitive in Australia's demanding healthcare market.

Beyond cost efficiencies, addressing Australia’s specific market conditions is essential. The country’s unique challenges - such as its vast geography and varying demand - require a manufacturing approach that is both flexible and resilient.

One effective strategy is adopting modular production systems. Instead of relying on fixed, high-volume production lines, modular systems allow manufacturers to scale output based on demand. This flexibility is particularly useful for catering to diverse clients, from metropolitan hospitals to regional healthcare facilities, each with different volume needs. At Mastars, modular production lines can seamlessly transition from initial prototypes to full-scale commercial runs without compromising quality or inflating per-unit costs. These systems are also designed to handle seasonal variations in demand, which are common in Australia due to elective surgery schedules and funding cycles.

Collaborating with Australian healthcare professionals early in the design process is another key approach. By involving clinicians from the outset, manufacturers can minimise costly revisions and ensure that scaled production aligns with real-world clinical needs.

Australia's geographic spread also calls for innovative solutions. Mastars employs a distributed service model to address this challenge. With design and engineering teams supporting clients across different time zones - from Perth to Sydney, Melbourne, and Brisbane - digital tools enable real-time design reviews and approvals, ensuring smooth project progress. These tools also foster collaboration, ensuring clinical insights are integrated into the manufacturing process for maximum efficiency.

Navigating regulatory requirements is another critical factor in scalability. Australia's Therapeutic Goods Administration (TGA) has stringent standards, and planning for these early in the process can prevent delays during market approval. Mastars works closely with Australian partners to ensure that all aspects of manufacturing, from production methods to documentation, align with TGA guidelines, simplifying the approval process.

Finally, supply chain resilience is essential for scalable manufacturing in Australia. Geographic isolation can lead to challenges like material shortages or shipping delays, particularly during global disruptions. To mitigate these risks, robust planning - such as maintaining strategic inventories and fostering relationships with multiple suppliers - is vital. Additionally, financial planning must account for Australia's irregular healthcare funding cycles. Flexible financing options and adaptive production schedules help manufacturers maintain cost efficiency despite fluctuating demand.

Scaling up custom implant production comes with its fair share of hurdles, but teaming up with the right partner can turn these into opportunities. By blending technical expertise with a deep understanding of the Australian market, Mastars offers a unique advantage.

Expertise plays a critical role in scaling. Mastars combines cutting-edge manufacturing capabilities with an in-depth knowledge of Australian regulations. From the initial design stage to TGA compliance and final quality checks, their end-to-end approach simplifies the production process. This means you won't need to juggle multiple vendors, and you can count on consistent quality every step of the way.

The financial upside of such partnerships is hard to ignore. With cost savings of up to 30% compared to traditional production methods, Australian clients see these benefits reflected directly in AUD-based quotes. These savings stem from optimised materials, reduced labour costs, and efficient digital workflows. Plus, when regulatory hurdles are addressed quickly, the financial gains are even more substantial.

Navigating regulations is one of the toughest parts of scaling implant production in Australia. Mastars' team of compliance experts ensures swift TGA approvals and alignment with ISO 13485 standards, cutting down on delays that can stall production. This proactive approach not only saves time but also provides the confidence to scale up operations without hesitation.

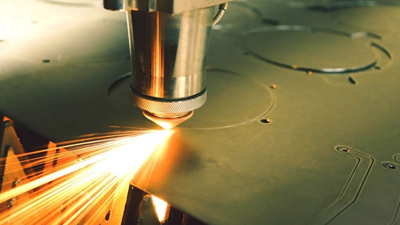

Technology is another key driver of success. Advanced manufacturing methods like selective laser sintering and electron beam melting allow for precise, biocompatible implants. These methods enable a smooth transition from prototype to full-scale production, all while maintaining the customisation that makes each implant unique.

Mastars also tackles the unique geographic challenges of Australia with its distributed service model. Whether you're in Perth, Sydney, Melbourne, or Brisbane, real-time design reviews and approvals keep projects moving forward. Combined with robust supply chain planning, this approach minimises risks tied to Australia's geographic isolation.

For Australian healthcare providers looking to scale custom implant production, the choice of manufacturing partner is crucial. Mastars delivers the technical know-how, regulatory insight, and local market expertise needed to thrive in Australia's healthcare sector. Their comprehensive approach ensures cost efficiency, quality, and scalability, making them the go-to partner for sustainable growth in custom implant manufacturing.

3D printing offers several important benefits compared to traditional manufacturing when it comes to creating custom implants. These include:

At Mastars, we utilise advanced 3D printing technologies to deliver high-quality, customised implants to our Australian clients. By combining our expertise with state-of-the-art manufacturing techniques, we provide efficient, precise, and scalable solutions for your custom implant needs.

Industry 4.0 technologies are transforming the way custom implants are produced, thanks to precise digital controls, real-time monitoring, and advanced automation. These tools work together to reduce errors, maintain consistent quality, and simplify manufacturing workflows.

With the help of AI and data analytics, manufacturers can identify and address potential defects before production even starts. This means implants are not only crafted with incredible precision but are also safer for patients, improving overall outcomes. Companies like Mastars are using these advanced technologies to create reliable, high-quality implants tailored to each individual, building trust and confidence in the process.

To align with Australia's Therapeutic Goods Administration (TGA) standards while expanding custom implant production, manufacturers should prioritise three critical areas:

At Mastars, we’re dedicated to helping Australian clients navigate TGA requirements with accuracy. With our expertise as a reliable one-stop manufacturing partner, we ensure your custom implants are produced efficiently and meet every Australian standard.