Understanding CNC Machining Tolerances

In the world of precision manufacturing, mastering tooling tolerances is fundamental to producing high-quality parts. CNC machining tolerances determine the permissible limit of variation in a physical dimension, directly impacting part functionality and assembly. For industries ranging from aerospace to medical devices, understanding and controlling these tolerances is not just important—it's critical.

What Are Machining Tolerances?

At its core, a machining tolerance specifies the acceptable range of deviation from a nominal dimension. Tighter tolerances mean the part must be extremely close to the exact specified measurement, while looser tolerances allow for more variation. Achieving the correct balance is a key aspect of the design for manufacturability (DFM) process, ensuring parts are both functional and cost-effective to produce.

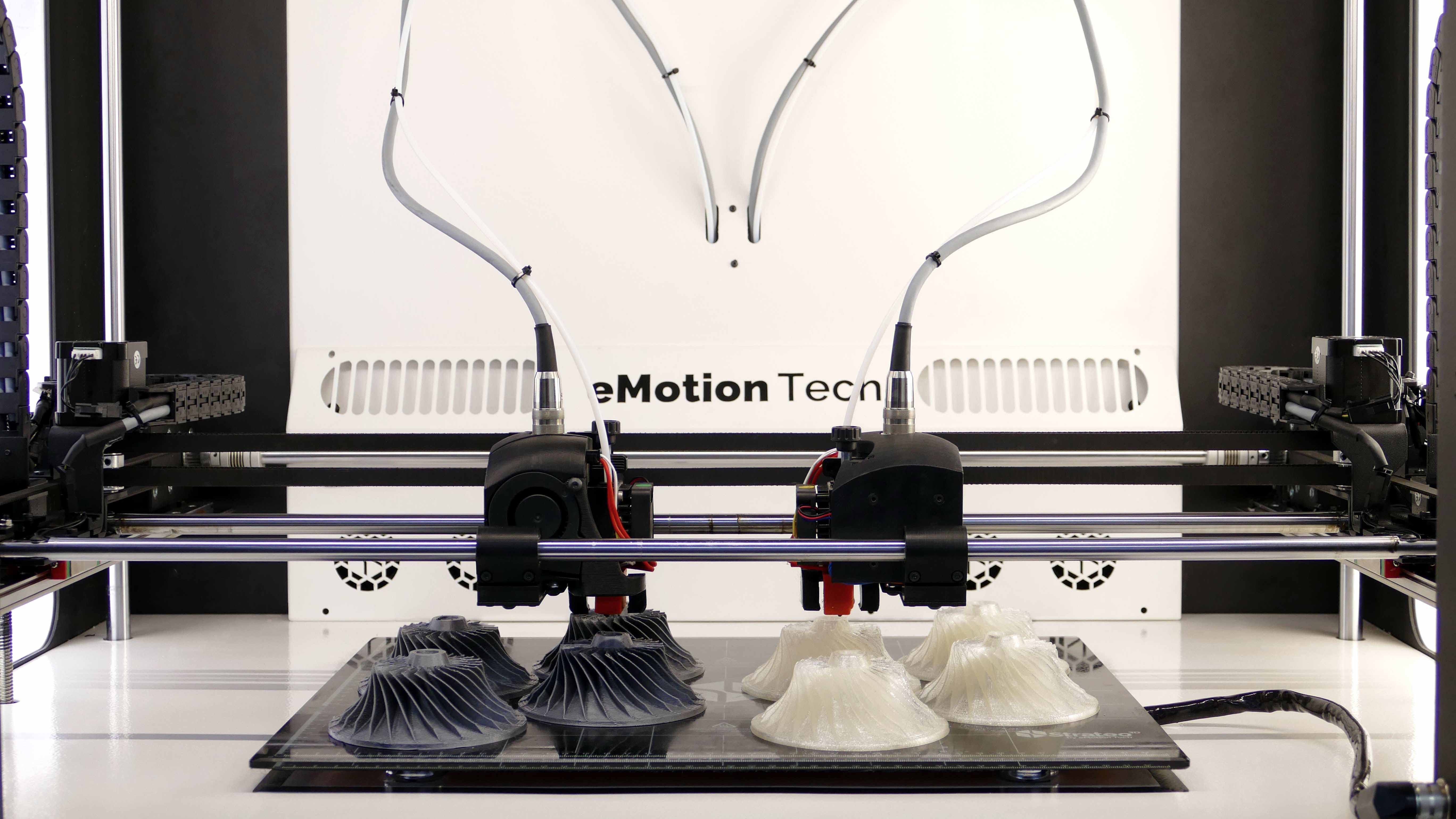

Standard vs. Tight Machining Tolerances

Standard machining tolerances are typically in the range of ±0.005 inches (±0.127 mm) for most CNC machining services. However, many projects demand much tighter tolerances, sometimes as precise as ±0.0005 inches (±0.0127 mm) or even finer for critical features. The ability to hold these tight machining tolerances consistently is what separates average machine shops from top-tier providers like Mastars.

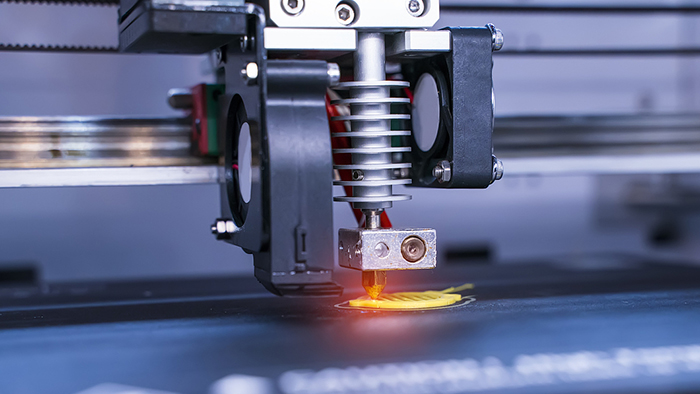

Factors Affecting Tolerance Achievement

Several key factors influence how tight a tolerance can be achieved in CNC production. The type of CNC machine, its condition, and its calibration play a monumental role in precision machining. Furthermore, the choice of material—whether it's aluminum, titanium, or engineering plastics—affects how it responds to cutting forces and heat, influencing final dimensions, a concept explored in resources like the ASM Materials Database.

Environmental and Operational Considerations

Temperature fluctuations during the machining process can cause both the workpiece and the machine itself to expand or contract minutely, a critical consideration for tight tolerances. The skill of the machinist or programmer in selecting optimal feeds, speeds, and cutting paths is paramount for precision manufacturing. Finally, the part's own geometry, including thin walls or deep cavities, can present significant challenges to maintaining stability and accuracy.

Tolerances and Cost Considerations

It is crucial to understand the direct relationship between tolerance tightness and part cost. Extremely tight tolerances require more time, specialized equipment, advanced metrology tools, and increased quality control inspections, all of which increase the price. Therefore, designers should always apply tight tolerances only where absolutely necessary for the part's function, a core principle of design for manufacturability that helps optimize project budgets.

Industry Standards and Tolerance Grades

Different industries have established standard tolerance grades to ensure interoperability and reliability. The International Organization for Standardization (ISO) provides globally recognized standards, such as ISO 2768, which offers guidelines for general tolerances. Adhering to these standards, as outlined in resources like this ISO 2768 overview from The Engineering Hub, ensures clear communication between designers and manufacturers worldwide.

Geometric Dimensioning and Tolerancing (GD&T)

For components that must fit together seamlessly, such as in engines or precision instruments, mastering geometric dimensioning and tolerancing (GD&T) is essential. GD&T provides a comprehensive system for defining and communicating engineering tolerances through a symbolic language on technical drawings. You can learn more about the fundamentals of this system from the American Society of Mechanical Engineers (ASME), which sets the governing standards.

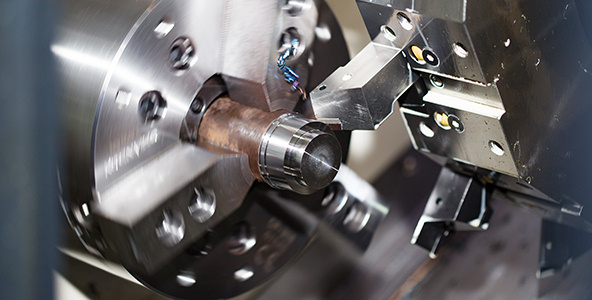

Quality Control and Verification

To verify that machined parts meet specified tolerances, rigorous quality control is non-negotiable. This involves using high-precision metrology equipment like coordinate measuring machines (CMM), optical comparators, and laser scanners. The National Institute of Standards and Technology (NIST) provides the foundational standards that ensure measurement accuracy and traceability in the United States, which top manufacturers adhere to.

Choosing the Right Manufacturing Partner

Choosing an experienced manufacturing partner is the most important step in ensuring your tolerances are met reliably. A seasoned provider like Mastars possesses the advanced technology, in-house expertise, and rigorous quality management systems necessary for complex projects. We excel in delivering high-precision machined parts that consistently meet even the most demanding tolerance requirements, providing our clients with unparalleled reliability and quality.