Plastic injection molding stands as a cornerstone of modern manufacturing, enabling the mass production of high-precision, complex parts with remarkable efficiency. From everyday consumer goods to critical medical and automotive components, this process is vital for creating durable, repeatable, and cost-effective plastic products. At its core, injection molding is a highly technical discipline that blends material science, mechanical engineering, and precision machining.

Deconstructing the Injection Molding Process

The process involves injecting molten plastic material into a mold cavity, where it cools and solidifies into the final part. The key stages and components include:

1. Clamping:The two halves of the mold—the stationary cavityand the moving core—are securely closed under high pressure by the clamping unitof the injection molding machine.

2. Injection:Plastic resin, typically in pellet form, is fed from the hopperinto a heated barrel. A reciprocating screwtransports the material forward, where it is melted by heat and shear force. This meltis then injected under high pressure through the nozzleinto the mold's sprue, runners, and gatesuntil the cavity is filled.

3. Cooling & Solidification:The molten plastic inside the mold cools and solidifies, taking the shape of the cavity. The design of conformal cooling channelswithin the mold is critical for achieving uniform cooling and minimizing cycle time.

4. Ejection:After sufficient cooling, the mold opens, and ejector pinspush the finished part out of the mold. The cycle then repeats.

Critical Terminology and Technological Considerations

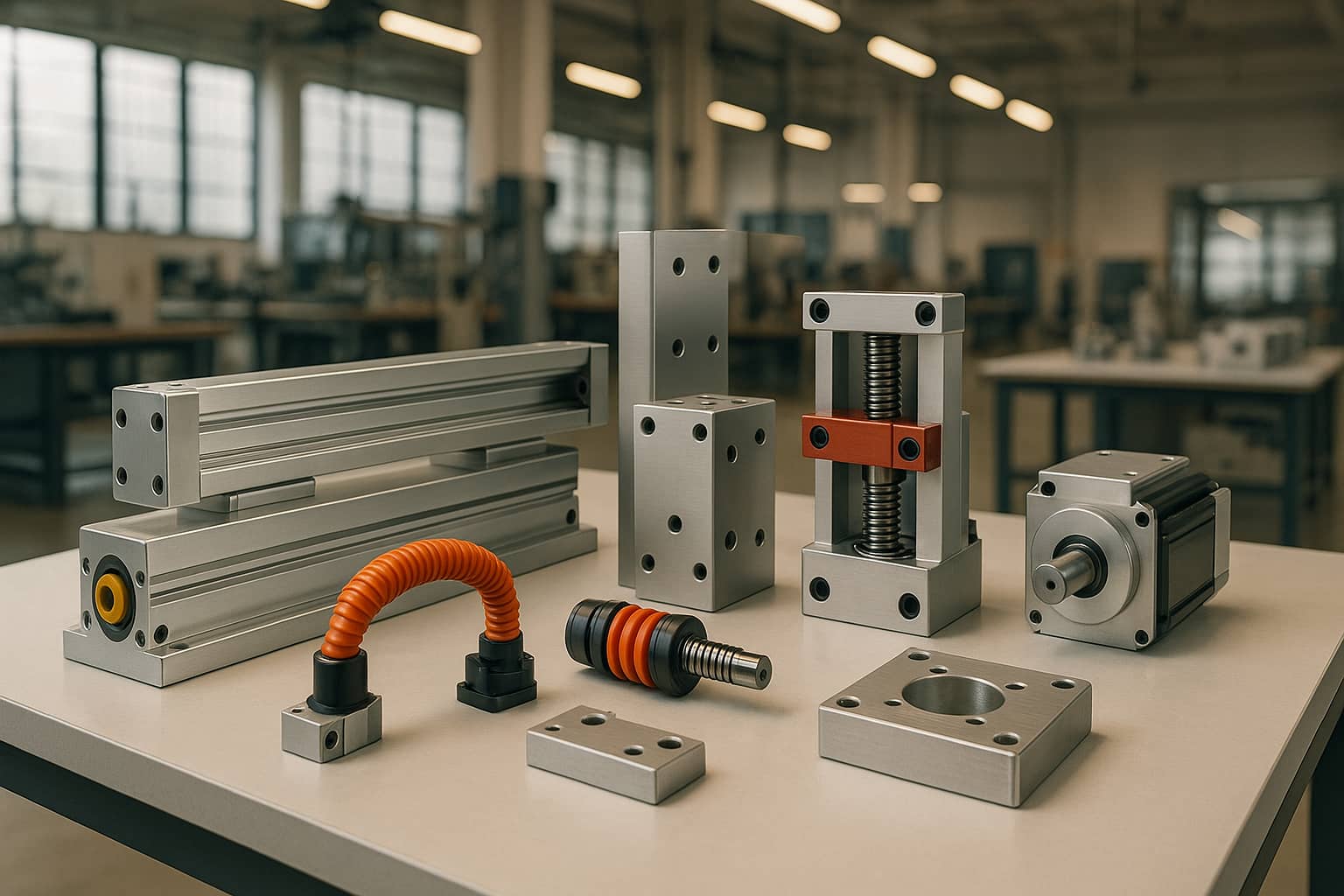

· Tooling:The mold (or tool) itself is a masterpiece of precision engineering, often made from hardened or pre-hardened steel or aluminum. Key features include:

o Parting Line:The line where the two mold halves meet.

o Draft Angles:Tapers added to vertical walls to facilitate part ejection.

o Undercuts:Features that prevent the part from being ejected directly, often requiring specialized mold components like slides, lifters, or collapsible cores.

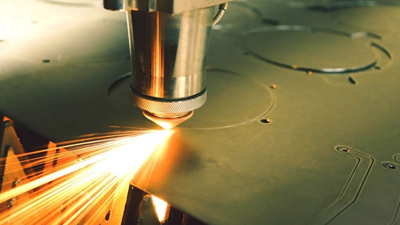

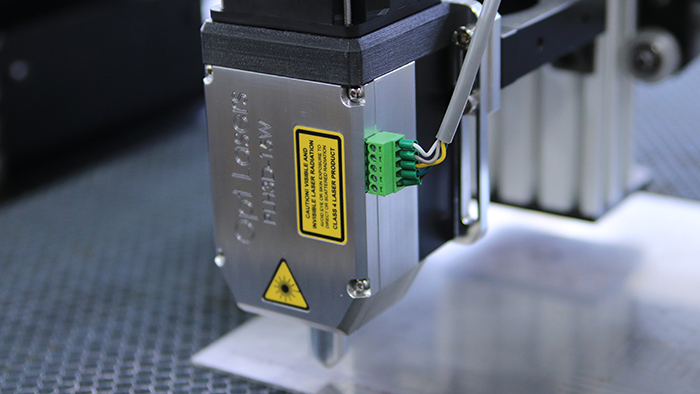

o Texturing:Applying surface finishes (e.g., EDM, laser etching) to the mold cavity to create a textured appearance on the final part.

· Materials:A wide range of thermoplasticsare used, each with specific properties. Common choices include ABS (impact resistance), Polypropylene (PP) for chemical resistance, Polycarbonate (PC) for clarity and strength, and engineering resins like PEEK for high-temperature applications. Additives like glass fiberare used to enhance structural integrity.

· Complex Processes:Advanced techniques like overmolding(molding a material over a substrate) and insert molding(encapsulating a metal component) allow for the creation of sophisticated multi-material parts.

Mastars: Your Strategic Partner in Injection Molding

For companies seeking to leverage the full potential of injection molding, partnering with an expert manufacturer is crucial. Mastarshas established itself as a leader in providing end-to-end injection molding solutions, from initial design consultation to high-volume production.

Mastars' service portfolio is built on a foundation of technical excellence and comprehensive capabilities:

· Expert Design for Manufacturability (DFM) Analysis:Before a single tool is cut, Mastars' engineers perform a thorough DFM analysis on customer designs. They provide actionable feedback on wall thickness uniformity, rib design, gate location, and draft anglesto optimize the part for manufacturability, cost, and performance, preventing potential defects like sink marks, warpage, or short shots.

· Precision Mold Making:Mastars operates a state-of-the-art tool room equipped with 5-axis CNC machining centers, EDM (Electrical Discharge Machining), and precision grinding equipment. This allows them to manufacture high-precision, complex molds in-house, ensuring full control over quality and lead times. They are proficient in building multi-cavity molds and family molds to maximize production efficiency.

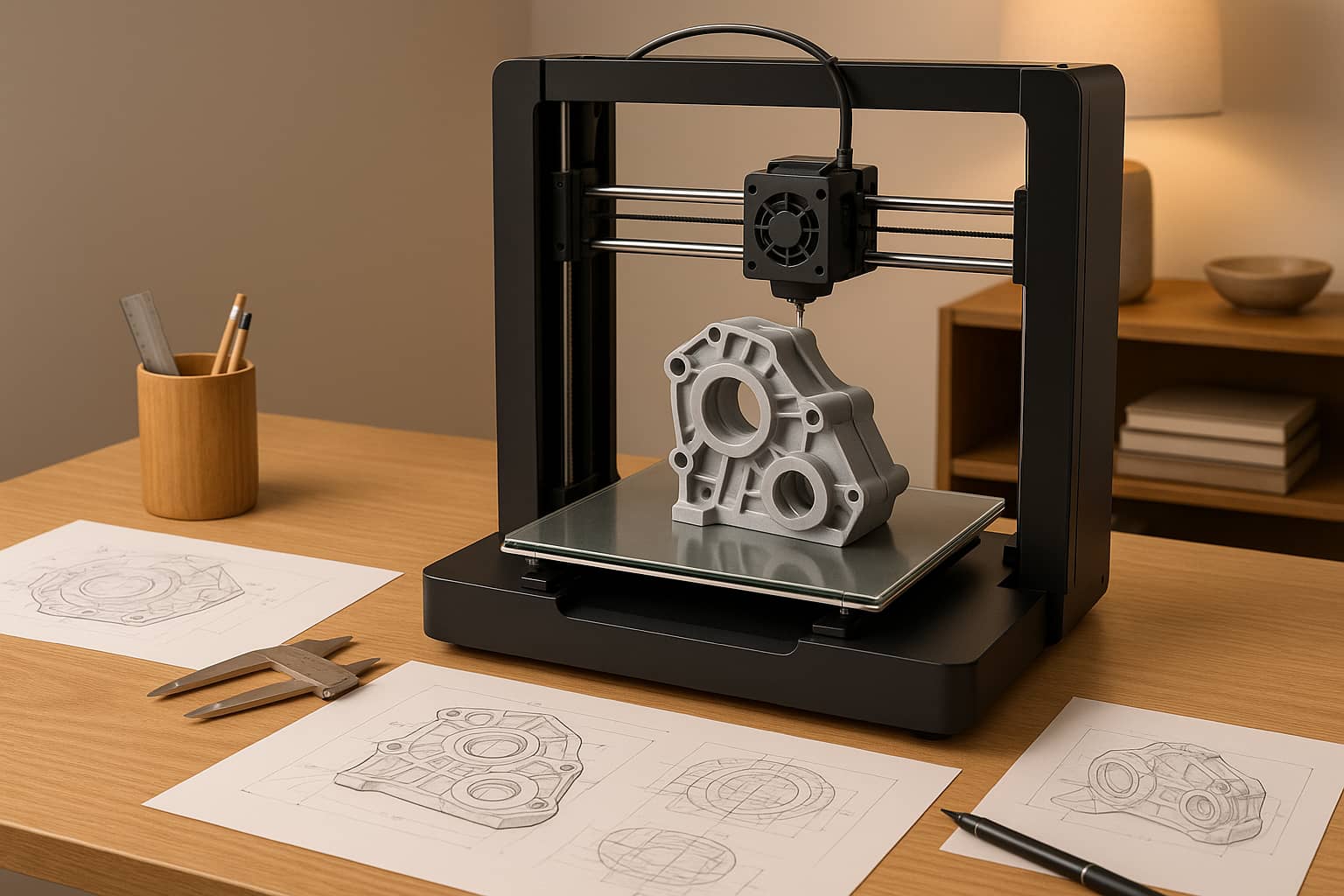

· High-Volume Production and Quality Assurance:With a fleet of injection molding presses of various tonnage, Mastars is equipped for both rapid prototypingand long-term, high-volume production runs. Their quality control process is integral, utilizing Statistical Process Control (SPC)and Coordinate Measuring Machines (CMM)to perform First Article Inspections (FAI)and ongoing dimensional checks, ensuring every part meets strict specifications.

· Value-Added Services:Mastars provides a complete suite of post-molding services, including ultrasonic welding, heat staking, and a variety of finishing options like pad printing, painting, and assembly. This turnkey approach simplifies the supply chain for their clients.

Conclusion

Plastic injection molding remains an indispensable and evolving manufacturing technology. Its effectiveness, however, is heavily dependent on the expertise of the manufacturing partner. Mastarsdistinguishes itself by combining deep technical knowledge in mold design and material science with robust manufacturing capabilities. By offering a seamless integration of design, tooling, production, and assembly, Mastars empowers businesses to bring high-quality plastic components to market efficiently and reliably, solidifying its role as a true partner in innovation.