Precision in CNC machining is essential across industries like automotive, medical devices, and electronics. Accurate machining reduces errors, improves quality, and lowers costs. Here are five critical factors to ensure machining accuracy:

The choice of cutting tools is a critical factor in maintaining precision during CNC machining. Using a worn carbide end mill, for example, can cause dimensional inconsistencies, while a carefully chosen and well-maintained tool helps achieve tight tolerances.

The geometry of a cutting tool directly influences the precision of machining. Tools with sharp cutting edges reduce cutting forces, which helps minimise deflection and vibrations during operation. On the other hand, dull tools require more force to cut, generating excessive heat that can distort the material.

Tool runout is another key factor. Even a slight runout can result in notable dimensional errors, particularly for parts requiring tight tolerances, such as bearing surfaces or components that need to fit together perfectly.

The material of the cutting tool also matters. Carbide tools generally retain their sharpness longer than high-speed steel options, offering consistent performance over longer production runs. For machining composites or non-ferrous metals, diamond-coated tools provide even greater durability.

To manage tools effectively, regular inspections are non-negotiable. Before starting a job, check cutting edges for wear, chips, or material buildup. A tool presetter can help verify dimensions and detect runout issues before the tool is mounted in the spindle.

Establish a replacement schedule based on actual cutting time. Since tool life depends on material and cutting conditions, tracking usage closely ensures tools are replaced before they fail unexpectedly during production.

Proper storage also plays a big role in tool longevity. Use dedicated holders or foam inserts to prevent cutting edges from contacting other surfaces. Maintaining consistent temperature and humidity in storage areas prevents thermal expansion issues when tools are moved to the machine.

Optimising tool paths can further extend tool life. For instance, climb milling often delivers smoother finishes and reduces wear. Always match speeds and feeds to the material and tool specifications rather than relying on generic settings.

These strategies create a solid foundation for managing tools effectively while addressing common machining challenges.

Monitoring tool wear in a fast-paced production setting can be tricky. In-process systems that track cutting forces and vibrations can help identify gradual wear before it starts to impact quality.

Managing tool inventory across multiple machines and operators also requires careful organisation. A centralised database that tracks tool specifications, usage history, and remaining life can prevent the use of worn or unsuitable tools. Pairing this system with monitoring solutions enhances overall reliability.

Thermal effects on tools are another challenge. Allow tools to stabilise thermally before starting precision cuts, and for high-volume operations, consider through-spindle coolant systems to maintain consistent tool temperatures.

Lastly, operator training is essential. Standardised procedures for tool selection, installation, and inspection ensure consistency, reducing variability caused by differing operator techniques. These measures collectively help maintain precision and efficiency in CNC machining.

Keeping CNC machines in peak condition requires regular calibration and maintenance. Over time, even the most advanced machines can lose their precision, which can lead to production errors and deviations from required tolerances. Routine upkeep ensures machines stay accurate and reliable, forming the foundation for smooth operations.

Calibration directly affects the dimensional precision of parts. A slight misalignment in the spindle, for instance, can lead to components falling outside acceptable tolerances. This is especially critical in industries like automotive manufacturing, where parts must fit seamlessly, and in medical device production, where even micrometre-scale errors can compromise functionality and safety. Factors such as dust, heat, vibration, and humidity can accelerate calibration drift, further impacting accuracy.

To maintain precision, it’s important to establish a proactive calibration schedule. For most machines, full calibration every 6–12 months is sufficient, but high-volume operations may need checks every 3–6 months.

The type of machine also plays a role. CNC routers and laser cutters, which are more complex, often require more frequent calibration compared to simpler mechanical systems. Similarly, machines processing thicker or harder metals endure greater strain, demanding more regular maintenance.

The machine's environment significantly influences calibration needs. Those operating in climate-controlled, low-vibration settings can go longer between calibrations. On the other hand, machines exposed to dust, heat, or excessive vibration need more frequent adjustments. Always refer to manufacturer and ISO guidelines to determine optimal calibration intervals.

Even with these measures in place, real-world challenges often arise.

Managing calibration across multiple machines can be tricky due to variations in machine type, age, and usage patterns. Analysing historical calibration data can offer insights into optimising future maintenance schedules. For example, machines showing rapid calibration drift may indicate underlying mechanical issues, while stable machines might allow for extended intervals.

The importance of the parts being produced should also guide calibration frequency. Machines manufacturing safety-critical components or those requiring extremely tight tolerances will need more frequent checks. Additionally, wear and tear naturally degrade machine performance over time, making condition monitoring vital for identifying when repairs or replacements are necessary.

A well-maintained calibration schedule helps catch deviations early, preventing costly errors and reducing the risk of production downtime.

After addressing strategies for managing tools and machines, it's equally important to focus on controlling temperature and environmental conditions. These factors directly affect the accuracy of CNC machining, as temperature shifts can cause materials to expand or contract. Let’s explore how these changes impact precision and what can be done to maintain consistent results.

Thermal expansion is a major issue in CNC machining. Even a small rise in temperature can cause metals to expand, affecting dimensions. That’s why it’s crucial to adapt control measures to suit the specific properties of each material.

Temperature changes don’t just impact the materials being machined - they also affect the machine itself. For example, spindle bearings can heat up during operation, potentially shifting the cutting tool’s position. Similarly, linear guides, ball screws, and even the machine bed may expand or warp slightly as the surrounding temperature fluctuates.

Beyond temperature, other environmental factors can also disrupt precision. Humidity changes, for instance, can impact certain materials and interfere with machine lubrication. Vibrations from nearby equipment or external sources can introduce positioning errors, especially during high-precision finishing tasks.

To combat these challenges, maintaining a stable workshop environment is essential. Consistent temperature and controlled humidity levels help minimise the risks of thermal expansion. Many modern CNC controllers come equipped with thermal compensation systems that use sensors to make real-time adjustments, but these systems work best when paired with proper climate control.

Coolants also play a critical role. Keeping coolant at an optimal temperature not only prevents thermal shock but also ensures effective cooling during operations.

Before starting precision machining, it’s a good idea to let machines reach thermal equilibrium. Running spindles and axes through their normal ranges can help stabilise temperatures. Similarly, allowing workpieces to acclimate to room temperature - especially if they’ve been stored in varying outdoor conditions - can significantly improve machining accuracy.

Despite best efforts, environmental challenges can still arise. Seasonal changes in workshops without advanced climate control systems can lead to dimensional drift and inconsistent performance. Monitoring production trends over time can help pinpoint these issues and guide necessary adjustments.

In cases where intensive machining generates localised heat that general climate controls can’t fully address, additional measures may be needed. These might include applying extra coolant, introducing cooling intervals between operations, or using infrared thermometers to monitor workpiece temperatures.

For facilities running multi-shift operations, even minor temperature changes between shifts can lead to uneven results. Implementing shift-specific compensation strategies or extending warm-up routines can help counteract these variations and ensure consistent quality.

Budget constraints often influence the level of environmental control a facility can implement. While industries requiring extremely tight tolerances may invest in advanced climate control systems, smaller workshops can still make meaningful improvements with targeted solutions. These might include localised temperature management, better insulation, or scheduling precision tasks during more stable environmental conditions.

Ultimately, identifying the environmental factors that most affect your operations and addressing them with practical, budget-friendly solutions can make a noticeable difference. Even small steps toward improving environmental stability can lead to better machining accuracy and more reliable results.

When it comes to CNC precision, the choice of material plays a key role. Beyond machine and environmental controls, the right material ensures components meet exacting dimensional standards. Thoughtful material selection works hand-in-hand with other factors to maintain the overall accuracy of the manufacturing process.

After calibrating your machine and controlling the environment, the next step to ensuring precision is setting up the workpiece correctly. Even the best tools and machines can't compensate for a poorly positioned workpiece. The way your part is secured in the machine directly impacts the success of every cut.

The positioning of the workpiece is critical. A shift as small as 0.01 mm can throw off dimensions and create vibrations that compromise precision. Poor setup not only causes dimensional errors but also leads to uneven forces and thermal distortions, which can worsen as machining progresses.

Clamping forces must be even to maintain accuracy. Uneven pressure can deform thin-walled parts, especially those with wall thicknesses under 2 mm. When these parts are released from the clamps, they tend to spring back, resulting in incorrect dimensions.

Establishing a precise reference datum is another key aspect of positioning. If the physical setup doesn't align with the design's intent, even the most accurately machined features will end up in the wrong place.

Consistency in workpiece setup is just as important as tool selection and machine calibration when it comes to achieving precision.

Achieving consistent workpiece positioning comes with its own set of challenges, but there are ways to address them effectively:

When assessing strategies to improve CNC machining accuracy, it's crucial to weigh the upfront costs against the long-term benefits. Here's a breakdown of several key options, highlighting their costs, effectiveness, and return on investment.

| Strategy/Technology | Initial Cost (AUD) | Annual Maintenance | Effectiveness | Implementation Complexity | ROI Timeline |

|---|---|---|---|---|---|

| Entry-Level CNC Upgrade | $30,000+ | 2–5% of machine value | High for basic precision | Medium | 2–3 years |

| Premium Spindle System | $5,000–$30,000 | ~$500–$1,500 | Very High | Low to Medium | 1–2 years |

| Cemented Carbide Tooling | 2× cost of tool steel | Tool replacement costs | High | Low | 6–12 months |

Cemented carbide tooling, though priced at more than twice that of standard tool steel, excels in demanding machining tasks. Its superior hardness and resistance to heat significantly extend tool life and enhance surface finishes, making it a worthwhile investment for applications requiring high precision.

Upgrading CNC machines involves annual maintenance costs that typically fall between 2–5% of the machine's value. However, these investments often lead to reduced per-unit costs over time as efficiency improves.

Premium spindle systems are another effective option, offering consistent precision improvements with relatively straightforward implementation. These systems can deliver a return on investment within 1–2 years by reducing scrap rates and improving cycle times.

For large production runs, the impact of these upgrades becomes even more evident. For instance, in runs of 1,000 parts, per-unit costs can drop by as much as 88%, showcasing the economies of scale achieved through strategic investments.

The complexity of the parts being machined also plays a significant role in determining the value of these investments. Parts with intricate geometries, multiple setups, and longer machining times benefit greatly from advanced tooling and precise measurement systems. On the other hand, simpler geometries may achieve satisfactory results with basic upgrades, reinforcing the importance of tailoring investments to specific production needs.

This analysis ties into earlier discussions on optimising CNC machining precision, providing a clearer picture of how strategic upgrades can enhance both performance and cost-efficiency.

Achieving precision in CNC machining depends on five key areas: tool selection, machine calibration, temperature and environmental control, material choice, and workpiece setup. Each of these elements plays a vital role in ensuring accuracy and consistency.

Temperature control and environmental conditions are often underestimated, yet they can significantly impact precision. Even the most advanced CNC machines can falter when thermal expansion or environmental fluctuations aren't properly managed. Similarly, the choice of material directly affects machining outcomes, influencing aspects like surface finish and dimensional stability.

Proper workpiece setup and positioning tie everything together. Even with precise tools and calibrated machines, poor fixturing can undermine the entire process.

By focusing on these principles, manufacturers in industries like automotive, medical devices, and consumer electronics can deliver exceptional quality and reliability. Fine-tuning precision not only reduces waste and rework but also strengthens a company’s competitive edge.

For Australian manufacturers - from small workshops to large-scale operations - evaluating current practices and making targeted improvements can redefine industry benchmarks.

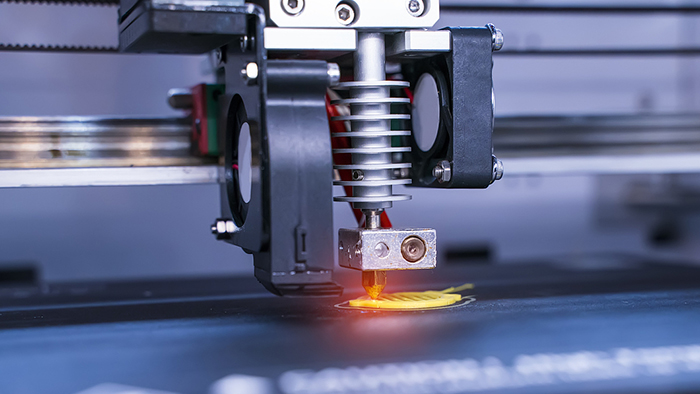

Choosing the right tool is a game-changer when it comes to achieving accuracy in CNC machining. The tool you select directly affects cutting forces, heat control, and the overall surface finish. By using the right tools, you can maintain consistent performance, reduce wear and tear, and avoid issues like material deformation during the machining process.

On top of that, investing in high-quality tools designed for the specific material you're working with can minimise errors, boost efficiency, and even prolong the life of both the tool and the machine. This is especially critical in fields like automotive, medical devices, and electronics manufacturing, where precision is absolutely essential.

Maintaining a steady temperature in a CNC workshop is key to achieving precise machining results. The recommended range is between 15°C and 25°C, as this helps minimise thermal expansion, ensuring consistent performance. To maintain this range, consider using air conditioning or climate control systems for effective temperature regulation.

Incorporating thermal management technologies, like motor temperature control systems, can further reduce the impact of heat on your CNC machines. Proper ventilation and air circulation are equally important to prevent heat build-up. These measures not only enhance machining accuracy but also contribute to prolonging the life of your equipment.

Properly setting up a workpiece is essential for achieving stability and precise positioning in CNC machining. A secure setup helps prevent unwanted movement or vibrations, which can cause errors and affect the final product's quality.

When the workpiece is aligned and secured correctly, it ensures consistent cutting paths and reliable contact between the tool and material. This is particularly critical in industries requiring high-precision components, such as automotive, medical devices, and consumer electronics. Investing time in a proper setup not only enhances the quality of the results but also reduces material waste and keeps costs in check.