Reducing weight and carbon is a key measure for the current automotive industry to move towards a circular economy. Currently, material suppliers are accelerating the development of low-carbon material solutions to help automobiles achieve carbon reduction.

Reducing the size of battery beams

BASF and Tier 1 supplier L&L Products developed a battery protection solution for the Ford 2022 F-150 Lightning. The team reduced the size of the crossmember in the battery system without compromising strength. The crossmember is a structural part designed to withstand high loads to keep the battery and occupants safe in the vehicle.

"Our solution using L&L Products' Continuous Composite System (CCS) and BASF's Elastocoat 74850 polyurethane pultrusion molding system eliminated the need for extensive redesign of the crossmember while providing strength, stiffness to the lightweight structure." said Chris Korson, BASF's marketing manager for high-performance materials chassis.

CCS combines fiber-reinforced pultruded composite carriers with highly engineered sealants and adhesives to form a planar profile. This process produces straight or curved composite profiles reinforced with continuous fibers and mats.

"This innovation also achieved three firsts for CCS: the first closed-section tubular CCS part developed, the first CCS body-in-white application and the first use of CCS in an electric vehicle," said Hank Richardson, product engineering manager for L&L Products.

The crossmember was also the first application of BASF's Elastocoat 74850 polyurethane pultrusion system implemented prior to the E-Coat process. In addition, the team used BASF's proprietary CAE modeling software, Ultrasim, to develop a new computer simulation method to show the behavior of the pultruded structure and accurately capture additional loads after composite failure.

ToyodaSynthesis (Toyoda Gosei) recently developed a cellulose nanofiber (CNF) reinforced plastic to reduce CO2 emissions throughout the life cycle of automotive parts from raw material procurement and production to recycling and disposal.

According to the report, the cellulose nanofiber is only one-fifth of the weight of steel, but five times the strength of steel. When used as a reinforcing material in plastics or rubber, products can be made thinner and foam molding becomes easier, which can reduce weight and help reduce CO2 emissions during the vehicle's journey. Second, when the vehicle is scrapped, the cellulose nanofiber reinforced plastic can be recycled with very little loss of strength during the heating and melting process, which makes it possible for recycling applications in automotive parts.

Toyoda Synthesis said its newly developed cellulose nanofiber reinforced plastic is mainly made by adding 20% of cellulose nanofiber to polypropylene, a general-purpose plastic for automotive interior and exterior parts. In practical applications, the reinforced plastic faces the challenge of reduced impact resistance. Toyoda Synthesis overcame this problem with its material blending design and kneading technology (kneading), bringing the impact resistance to a level suitable for automotive parts. The company says it will continue to work with CNF material manufacturers to reduce costs.

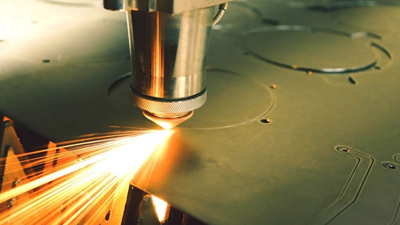

Carbon fiber that can reduce the weight of battery cases by 50 percent

SGL Carbon, a supplier of graphite and carbon fiber composites, will present its composite solutions for electric vehicle battery cases at the JEC Composites exhibition in Paris in May 2022. According to the report, SGL is improving the automation of the stacking of carbon fibers for lightweight structures in the production process, reducing material waste to save resources and reduce carbon emissions from carbon fibers.

It is understood that the use of SGL carbon fiber composite materials made of battery housing, than the response of steel housing to reduce the weight of 50%, it is in the fire resistance, rigidity, acoustics, as well as heat shielding, electromagnetic shielding performance can meet the corresponding requirements of the car. With the help of carbon fiber composites, sensors can be integrated for the detection of damage to the bottom of the electric vehicle.