Mastars has earned a reputation for being able to handle all projects, custom insert molding, and other complicated projects much faster than with traditional tooling, often helping our clients get to market shortly.

Plastic injection molding>

Sample parts are included with each new tooling order for customer review > No minimum quantity – Injection molds are our specialty > Fast and competitively priced Engineering Changes allow us to react very quickly to design updates and to test multiple concepts

Plastic injection molding>

Sample parts are included with each new tooling order for customer review > No minimum quantity – Injection molds are our specialty > Fast and competitively priced Engineering Changes allow us to react very quickly to design updates and to test multiple concepts

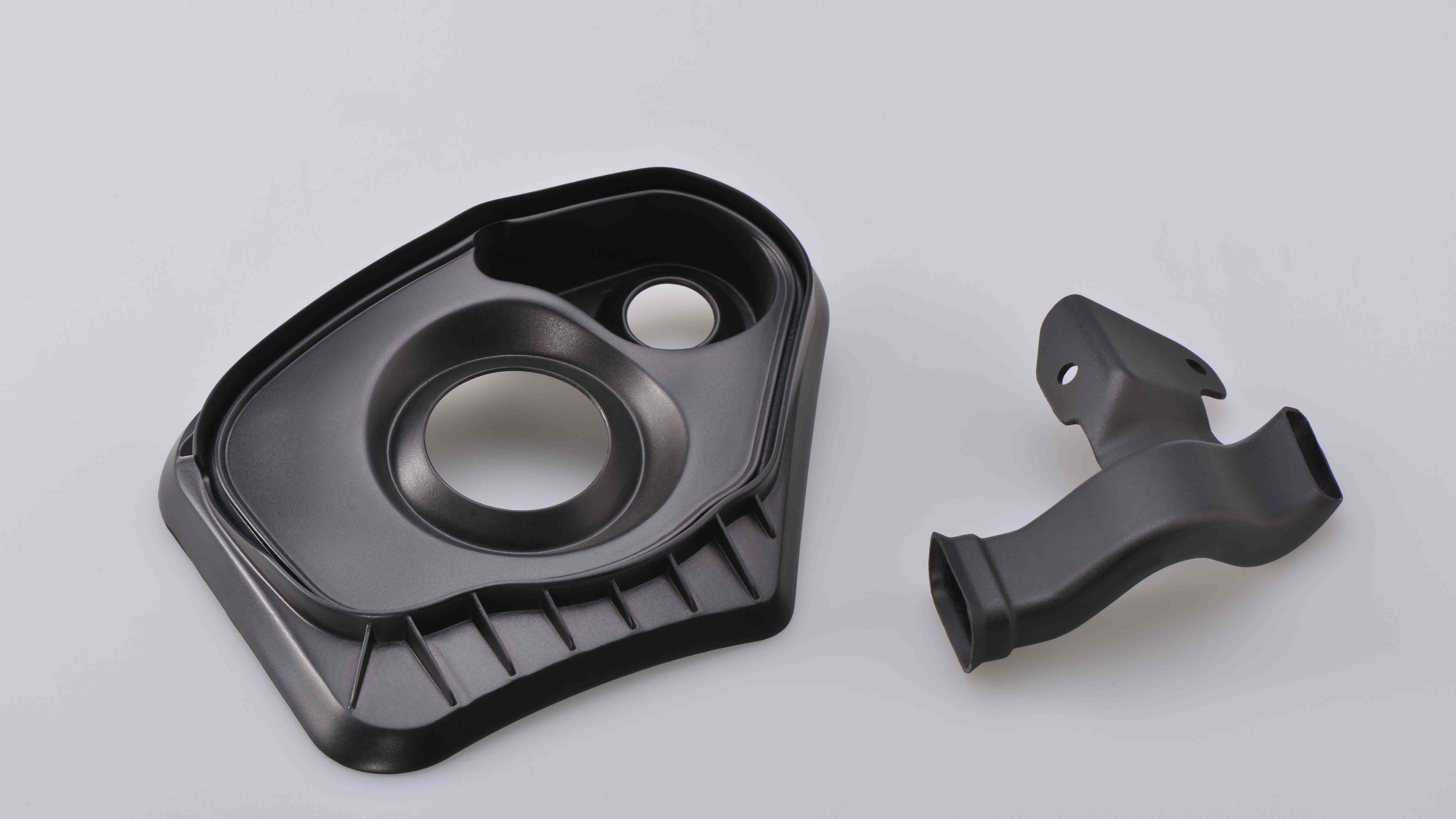

Stock materials We also stock common resins for fastest possible delivery

Stock materials We also stock common resins for fastest possible delivery

Special materials We can source any commercially available material for client requirements in the appropriate volume

Special materials We can source any commercially available material for client requirements in the appropriate volume

Customer supplied materials Customers with proprietary materials or those who wish to supply the material from their source may arrange for us to produce parts from their materials

Customer supplied materials Customers with proprietary materials or those who wish to supply the material from their source may arrange for us to produce parts from their materials

What are the factors affecting the machining of thin-walled parts?|mastars

What are the factors affecting the machining of thin-walled parts?|mastars

Understanding Tesla Factories-rapid prototyping services

Understanding Tesla Factories-rapid prototyping services

Tighter Tolerance Requirements Promote Micro Molding Technology Innovation

Tighter Tolerance Requirements Promote Micro Molding Technology Innovation

Badminton racket manufacturing process|rapid cnc machining

Badminton racket manufacturing process|rapid cnc machining