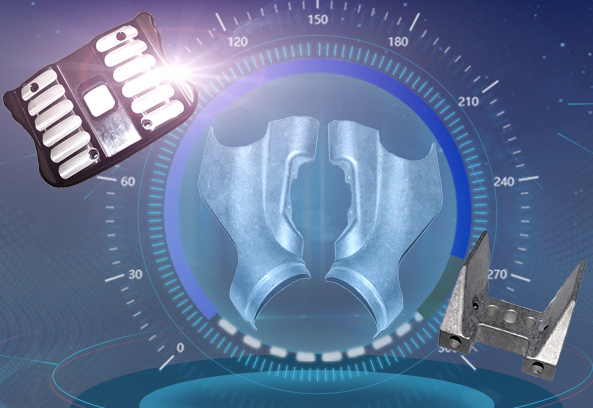

If you have decided to use CNC materials for part production, you have made an excellent choice. Opting for CNC technology, you will gain multiple opportunities to create the perfect custom product. Firstly, you need to understand that CNC technology is highly repeatable and precise, offering a better manufacturing process for part and prototype production. Furthermore, this technology employs a subtractive process, where computer-controlled tools cut the material, ensuring you always get a professional-quality product.

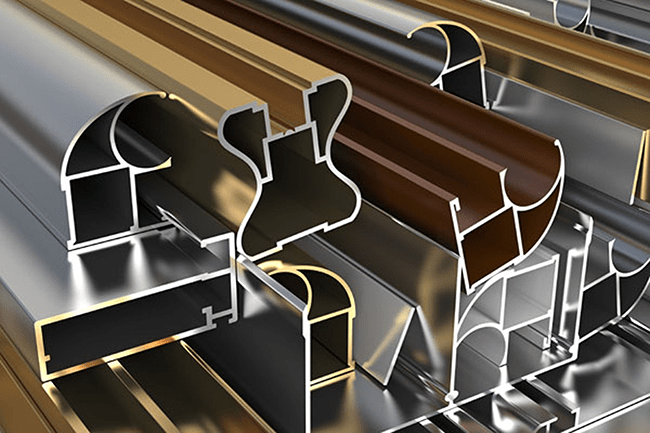

One of the biggest advantages of using CNC technology is the diversity of materials. This machine can easily handle aluminum alloys and steel, while you can also use plastics and brass for optimal parts. After the work is completed, you also have a variety of surface treatment options, enjoying multiple benefits such as flexibility and efficiency. Let's delve into CNC materials and understand the material selection process in detail.

Selecting materials for a CNC machine is not complicated, but it would be ideal to get expert help. Besides that, you can also get some useful advice from this article. Here are the basic steps for selecting CNC materials:

This includes thermal, mechanical, and other requirements, while also needing to consider surface treatment processes and machining costs. You need to check the environmental conditions the part will interact with.

You need to select some alternative materials that can meet all the requirements of the project. For example, consider the machine's cost and performance.

When faced with two or more design options, some trade-offs might be necessary. For the selection of the best material, you can consult expert opinions. In cases of combined use, you can consider combinations of plastic and metal materials, grouping them for comparison. Metals provide durability and hardness, while plastics offer lightweight properties. Additionally, you need to consider durability, temperature ratings, and the cost of material processing.

The selection process includes some basic steps, all of which are crucial when you use a CNC machine. Let's look at the following factors in detail:

CNC machines are constantly evolving, with better components appearing every year. Similar materials are used for different products, and they also have different applications. For example, in terms of insulation, if you are insulating for an alcohol tester, it will be different from other procedures. On the other hand, when you are insulating for a soundproofing system, it will have different uses and specifications. Therefore, it is best to consider the final application scenario beforehand.

Indoor environments are different from outdoor environments and are also affected by weather conditions. Before starting a project, you need to check the weather conditions and pay attention to humidity levels. Thereafter, you can start work, and the material should be resistant to oxidation effects that cause rust.

High stress can damage CNC materials. When you consider materials for part production, it is very important to check the stress load section. If the part is subjected to high stress, it will not be able to withstand the pressure and may deform.

When you are looking for the perfect CNC machined part, you need to check the dimensional tolerances. This can become an automated part of the process, but you must never overlook the importance of dimensional tolerances. It will affect not only the parts produced but also the entire process. You need to understand the tolerance grade of the part. If you are dealing with old items, then checking the tolerances is a good idea.

In the components of a CNC machine, you need to use fasteners, which is very important when selecting materials. The material you choose will affect the security of the fasteners and determine their suitability. Different materials have different properties, such as galvanic corrosion, brittleness, corrosion resistance, and strength. Therefore, you need to choose materials that provide better strength and compatibility for the part.

In this case, the best material is stainless steel, but that doesn't mean it is the safest choice for your product. If you are looking for a fastening method for a new part, then it should fit perfectly. If you cannot determine the correct fastener, the part will not function properly.

When you need the part to withstand the forces of the machine, the operating temperature is very important. You need to ensure that the material's melting point is lower than the operating temperature. You also need to pay attention to temperature fluctuations in the function and check if the material can withstand them. Some materials are specifically designed to tolerate temperatures, while others will expand, show signs of warping, or may decompose after a while. If the temperature is extreme, it may also compromise the part's durability.

These details are crucial when using CNC items, and you can determine the temperature so that the part does not deform, and you get perfect production. You need to understand the connection between CNC materials and the part to achieve the perfect design.

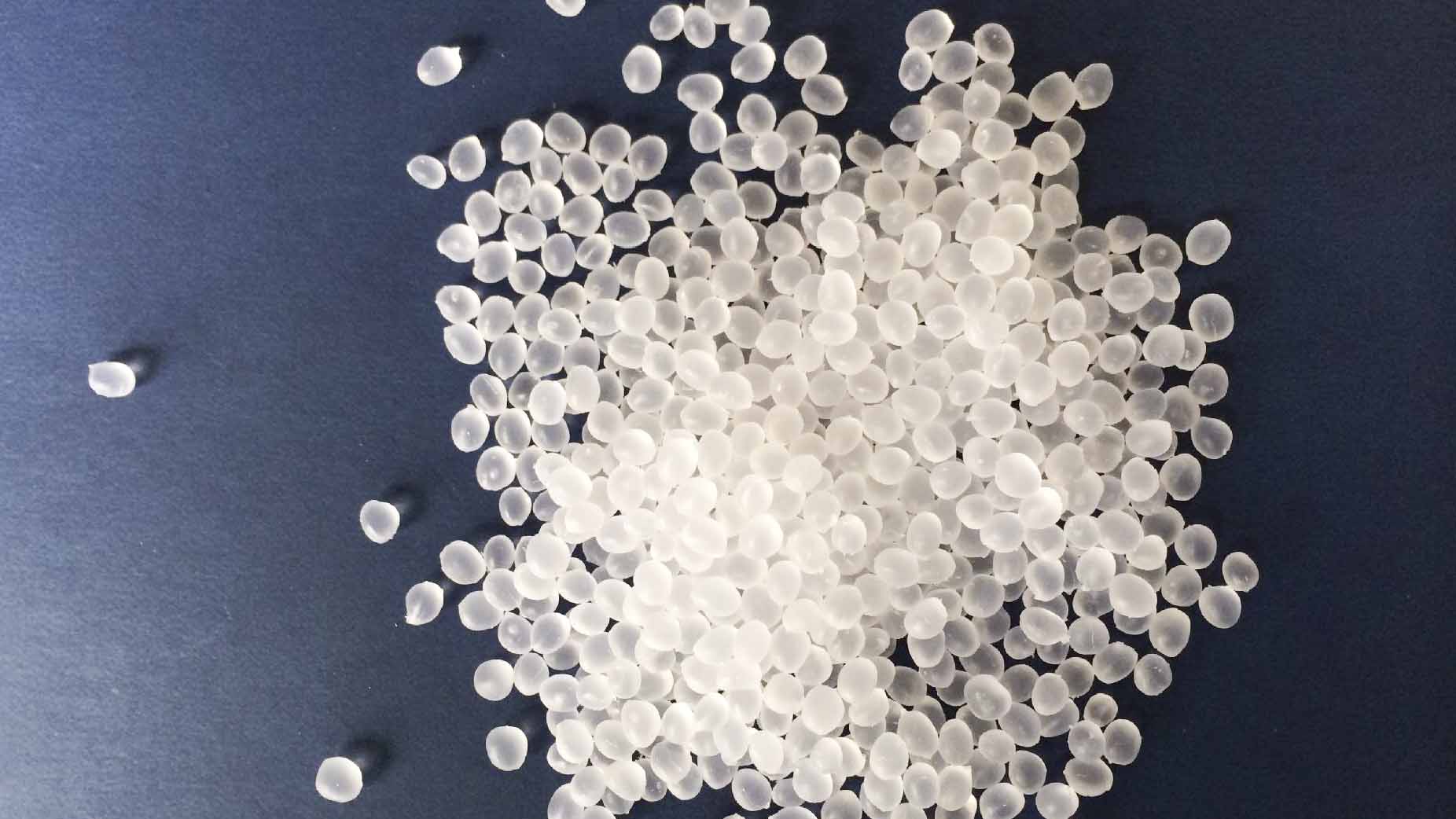

High temperatures always have an effect on CNC machine materials. Polyvinyl chloride is a plastic material that cannot maintain performance at high temperatures, and the same goes for PVC. Although it has a good heat resistance rating, its operating temperature is 167 degrees Fahrenheit. Stability is lost at 280 degrees, making it unsuitable for part production projects. Therefore, when you are looking for high-temperature materials, look for the most suitable ones.

Depending on what you want to do with the CNC component, you need to check the weight of the selected material. Bigger is not always better, and too little will not give the right result. Therefore, you need to check the appropriate ratio and consider the cost.

Based on the cost and characteristics of the materials, you need to choose the best CNC product. The most suitable materials in this case are:

The best way to decide on CNC materials is to talk to experts near you. Once they understand the project, they will help you decide which material should be used. You will also get help with project completion and budgeting. However, you can also learn about an overview of popular CNC materials and decide which one is best for part production. Here is the list:

This metal has the best corrosion resistance, including for plating projects, and has better machinability. It is a famous CNC material, very suitable for part production projects. This material comes in various grades and has a good strength ratio, meaning it is suitable for most products. Experts use this material for defense mechanisms, automotive construction, and the aerospace industry.

Professionals use stainless steel for different projects in the industry, mainly because of its ability to resist corrosion. It is widely used in almost every part production center. You will get project materials of different grades, and although the cost is higher, you will get the best surface finish.

In most cases, CNC plastic materials are used for better electrical insulation and cost-effectiveness. Plastics are very important for making prototypes when finishing the final product. You will also get parts of different grades, such as Polypropylene, Polycarbonate, PEEK, Nylon, Garolite, G-10, Acrylic.

This is a metal alloy with good machinability and better electrical machining performance. It offers low friction and is very suitable for various applications.

After reading this article, you will clearly understand that working with CNC machines is highly adaptable and offers better diversity in selecting part materials. For more information, you can always contact experts.

We employ mature prototyping technologies (CNC machining, vacuum casting, 3D printing, etc.), accept new concepts or designs and turn them into reality, rapidly and economically develop and evaluate new products with less risk. Through the lessons learned from prototyping, we provide thoughtful and proactive mold design/manufacturing and mass production handling, offering a full range of one-stop solutions from injection molding, die casting, CNC machining to final assembly.

Our purpose is to create value for customers by manufacturing quality products that improve people's lives. We help a diverse clientele design, manufacture, and deliver products that make the world a better place.

Our vision is to become the world's most reliable and valuable manufacturing supplier.