Mastars focuses on the 3D printing industry, providing plastic 3D printing services, 40 + kinds of materials, using sintering molding and light curing technology, supporting model verification and functional testing, and free quotation for drawings!|3d printing prototyping|3d printing manufacturing.

To understand what is 3D printing injection mold, we start with conventional injection molding.

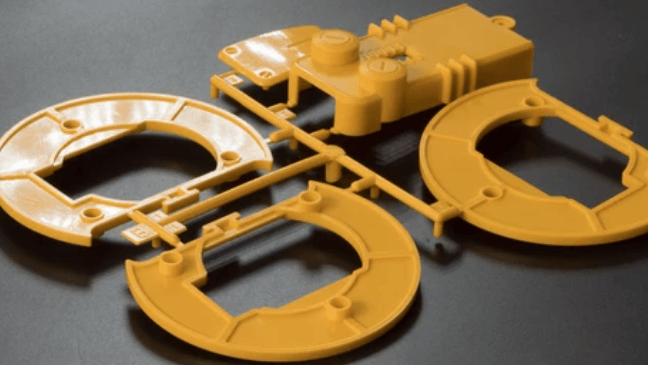

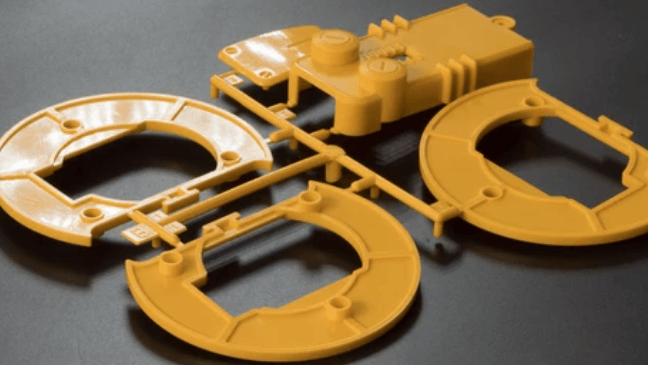

Injection molding is one of the most common manufacturing processes in the plastic industry. Essentially, the molten plastic is injected into the mold cavity to harden as it cools, and then the mold is opened and the plastic part is taken out.

Injection molding is mainly used for mass production because of its high upfront costs in design, testing and processing. Of course, the more parts are produced, the unit price will drop sharply, which is the reason and advantage of mass production using injection molding.

Why 3D printing?

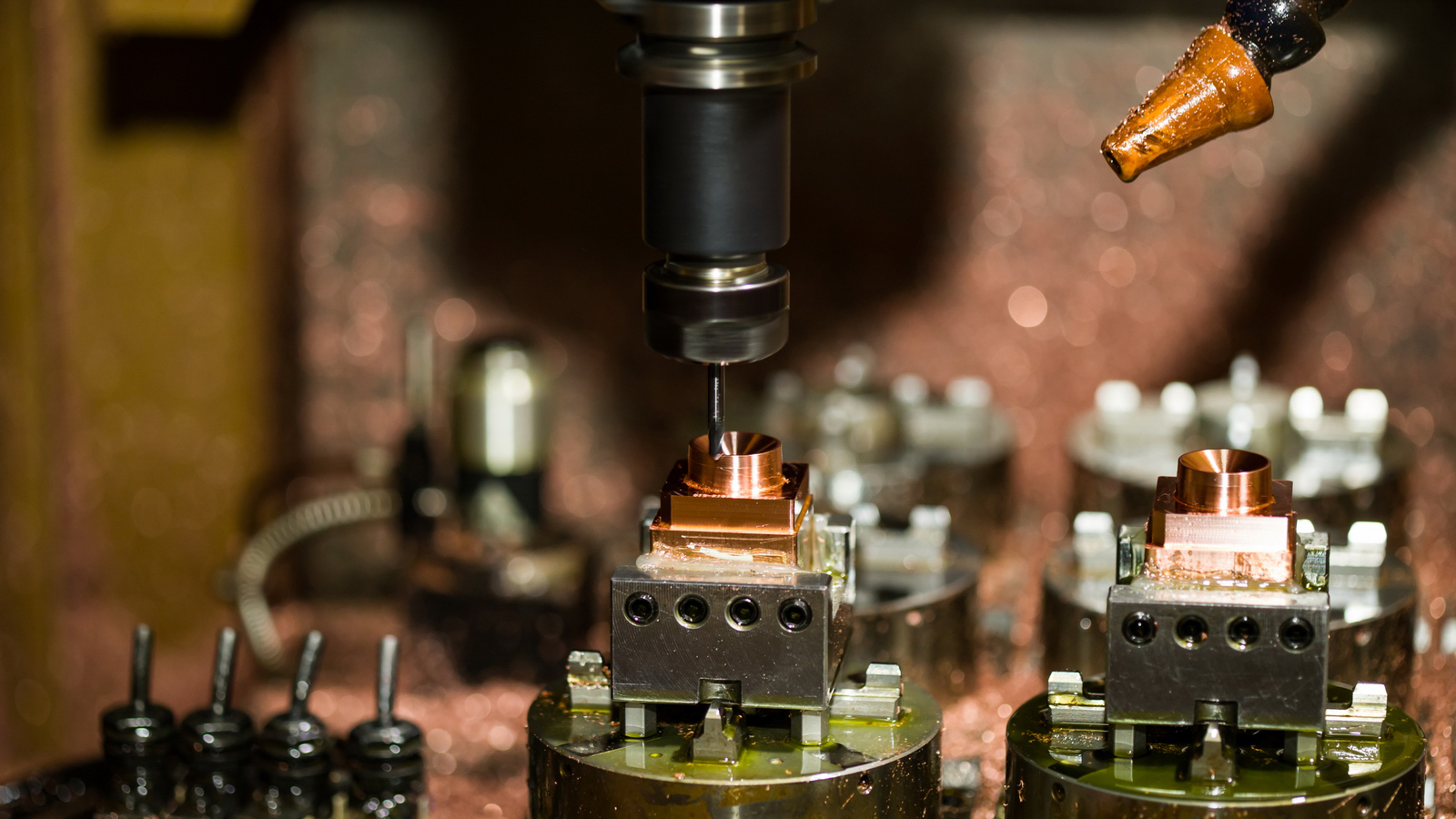

The injection mold itself is a metal block with cavities, which determine the shape of the product. Traditionally, the mold is designed and produced by computer numerical control (CNC) milling machine, which is very expensive.

Because molds are usually made of metals such as steel and aluminum, it is difficult to change once they are produced. Therefore, 3D printing injection mold provides a cheap and flexible alternative.

Let's take a look at how to actually print 3D injection molds, the advantages and disadvantages, the new development of 3D printing injection molds, and the skills of final printing.

How to 3D print molds?

data processing

3D printing injection molding is similar to printing other 3D printing objects:

Injection molds are designed using CAD software, such as AutoCAD or fusion 360.

The design file is saved in STL format and sliced into G code.

Use a 3D printer to print the mold layer by layer.

Install the mold into the metal frame and prepare for injection molding.

Materials of 3D printing injection mold since the basic process of 3D printing injection mold has been introduced, let's see what materials can be used.

Generally speaking, you need products with high strength and stiffness to withstand the pressure generated during the injection process. Moreover, it will need to have high temperature resistance.

The following are several common materials for

3D printing injection molds:

PETG

ABS

nylon

PP

TPE

POM

You can use SLM, SLA, FDM, and SLS to complete 3D printing of injection molds. In other words, because the high dimensional accuracy and smooth surface are very suitable for injection molds, SLA is the preferred 3D printing method for the production of injection molds.

One thing you should know about metal frames and their role in injection molds. The frame supports the pressure and heat generated during injection molding. Since the metal frame can be widely used, only the core part of the mold needs 3D printing, so it is easy and flexible to change the design. However, in the case of 3D printing of the whole mold, more materials and longer printing time are required.

Advantages and disadvantages of 3D printing injection mold

advantage

Low cost: the traditional method of producing injection mold is very expensive and time-consuming, which requires the precision machinery and professional knowledge of the mold manufacturer. 3D printing is a cheaper way to make molds. It is reported that compared with traditional technology, 3D printing mold can save up to 80% of the cost.

Flexibility and efficiency: 3D printing greatly reduces design and production time. Anyone with 3D printing experience can print the mold. If you are not satisfied with it, you can simply adjust the design and print another one.

Applicability of small batch production: the initial cost of injection molds made by traditional methods (such as CNC milling) is very high. Therefore, it is cost-effective only when the output is large enough. On the other hand, the manufacturing cost of 3D printing mold is much cheaper, and if there is no high initial cost, it is best to use 3D printing mold to complete small and medium-sized batch production.

shortcoming

Longer production time: because the thermal conductivity of plastics is lower than that of metals, it takes longer for 3D printed plastic molds to produce products, which prolongs the overall production time and reduces productivity.

Shrinkage: like many other 3D printed objects, the injection mold of 3D printing may shrink when it cools, which is a common problem in 3D printing. This can cause problems when precise dimensions are required.

Weak structural integrity: most 3D printing molds are made of plastic and cannot withstand high temperature and high pressure for a long time. This will cause the 3D printed injection mold to age at the gate and weld.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China