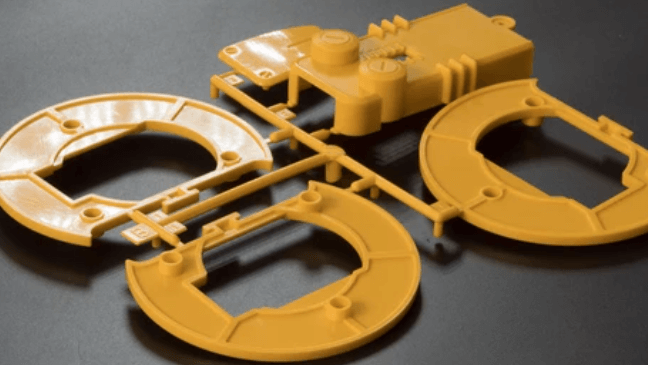

Multi Jet Fusion technology claims to have much faster printing speed and much higher material utilization than other additive manufacturing technologies, and has great application potential.

Mastars provides

rapid prototyping services,

rapid CNC machining,

3D printing,

rapid sheet metal prototyping, manufacturing, mass production, mold reproduction and other professional companies, to provide customers with a comprehensive, professional product manufacturing needs.

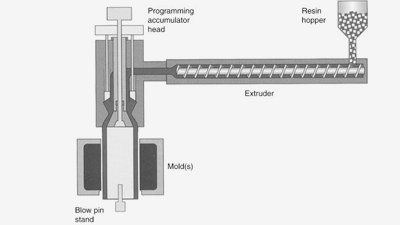

The forming steps of multijet fusion are as follows:

1) Laying of formed powder;

2) Spraying melting agent;

3) Spraying refining agent;

4) Apply energy to the molding area to melt the powder.

5) Repeat the process until the end of processing,

The core of HP printer is two modules located on the workbench: called "powder spreading module" and "hot nozzle module". "Powder spreading module" is used to lay powder materials on the printing table.

The "hot nozzle module" is used to spray the two chemical reagents of "melting agent" and "refiner", and the module is the biggest highlight of HP's printer - it can spray the two reagents at 30 million drops per inch per second.

Main advantages of multi jet melting (MJF) technology:

1. High strength nylon 12 powder material is adopted (the reuse rate is 80%), and the average cost of consumables is half of that of SLS process and one quarter to one fifth of that of FDM;

2. The printing efficiency is about 6 ~ 10 times faster than SLS and more than 10 times faster than industrial FDM;

3. Compared with SLA light curing, HP MJF powder formed parts have better comprehensive mechanical properties and thermal deformation resistance.

4. No supporting structure is required. When printing, all blank spaces are filled with unused loose powder

5. The single cost is only half of that of FDM and SLS solutions

Application of MJF:

Automobile: MJF

3D printing is helping automobile and automobile manufacturers reduce parts production costs and improve operational efficiency

Medical and dental industry: able to produce tools with small smell, mainly for medical and therapeutic fields. They were able to use MJF printers to produce durable, highly detailed housings for their prototypes with complex geometries.

Consumer goods: many types of consumer goods need to produce a small number of parts with complex shapes. MJF stands out because of the high production speed and durability it can provide.

Mastars has gradually developed into a solution service provider integrating design, service and sales. Mastars provides multi jet fusion services for prototypes and high-volume on-demand 3D printing projects. For more information about jet melting technology, please contact us.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China