Forging: Professional Terminology

Category 1: Fundamental Processes & Classifications

|

Term |

Definition & Context |

|

Forging |

The manufacturing process of shaping metal

using localized compressive forces, typically delivered by a hammer, die, or

press. |

|

Hot Forging |

Forging performed above the metal's

recrystallization temperature. This increases ductility and reduces required

force, allowing for complex shapes. |

|

Cold Forging |

Forging performed at or near room

temperature. This increases strength via strain hardening and provides

excellent dimensional accuracy. |

|

Warm Forging |

Forging performed below the

recrystallization temperature but significantly above room temperature. A

balance between hot and cold forging. |

|

Open-Die Forging |

Forging between simple, flat or contoured

dies where the workpiece is not fully constrained. The operator manipulates

the workpiece to achieve the desired shape. Ideal for large, simple parts. |

|

Closed-Die Forging |

Forging between two dies containing a

precut impression of the desired part shape. The workpiece is fully

constrained within the die cavity. Also called Impression-Die Forging. |

|

Roll Forging |

A process where a bar stock is passed

between two contoured rolls that progressively reduce its cross-section and

increase its length to form a part (e.g., a tapered lever). |

|

Upset Forging |

A process that increases the diameter of a

stock by compressing its length. Performed horizontally in a specialized

machine. |

|

Isothermal Forging |

A specialized process where the die is

heated to the same temperature as the workpiece. Used for superalloys and

other difficult-to-work materials to minimize cooling and reduce forging

pressure. |

Category 2: Equipment & Tooling

|

Term |

Definition & Context |

|

Hammer (Drop Hammer) |

Equipment that deforms the workpiece by the

impact energy of a falling ram. Can be gravity-driven (drop hammers) or

power-assisted. |

|

Press (Forging Press) |

Equipment that applies a slow, controlled,

compressive force to deform the workpiece. |

|

Mechanical Press |

A press that uses a motor and a mechanical

mechanism (e.g., crank, eccentric) to move the ram. |

|

Hydraulic Press |

A press that uses hydraulic cylinders to

move the ram. Capable of the highest forces and full-tonnage at any stroke

position. |

|

Die |

A hardened tool steel block that contains

the impression of the part to be forged. It is the core tooling in forging. |

|

Die Holder / Bolster |

A heavy block that holds and supports the

die assembly in the press or hammer. |

|

Punch |

The male part of a die set that performs

operations like piercing. |

Category 3: Workpiece & Material States

|

Term |

Definition & Context |

|

Ingot |

A large, cast metal block that is the initial

product of a primary metal facility. Often used as the starting stock for

large open-die forgings. |

|

Billet / Bloom |

A semi-finished product of a square or

rectangular cross-section, typically produced by rolling an ingot. A common

starting stock for forging. |

|

Bar Stock |

Long, straight lengths of metal of a

specific cross-section (round, square, hexagonal), used as feedstock for many

forging processes. |

|

Blank |

A pre-cut piece of stock (from a billet or

bar) that is ready to be placed into the forging die. |

|

Preform |

A preliminary forged shape, often from an

earlier forging operation, that is designed to distribute metal optimally

before the final forging blow. |

Category 4: Die & Part Features

|

Term |

Definition & Context |

|

Parting Line (P/L) |

The plane where the two die halves meet. It

is often visible as a line on the finished forging. |

|

Draft Angle |

A taper applied to the vertical walls of

the forging to allow for its ejection from the die cavity. Essential for part

removal. |

|

Flash |

The thin layer of metal that is forced out

into the gap between the die halves during impression-die forging. It is

later trimmed off. |

|

Flash Land |

The narrow, flat surface on the die that

forms the flash and creates the resistance necessary to ensure the die cavity

is completely filled. |

|

Gutter |

The recess in the die outside the flash

land that allows space for the excess flash to flow. |

|

Rib |

A thin, raised wall on a forging. |

|

Web |

A thin, flat section of a forging that

connects ribs and other features. |

|

Die Cavity |

The hollow impression in the die that gives

the forging its shape. |

|

Shut-off |

A sealing surface within the dies that

prevents metal from flowing into certain areas, often used to create internal

passages. |

Category 5: Metallurgy & Quality

|

Term |

Definition & Context |

|

Grain Flow |

The directional pattern of the metal's

grain structure that is aligned along the contours of the forging during

plastic deformation. This is the primary reason for the superior mechanical

properties of forgings. |

|

Recrystallization |

The formation of a new, strain-free grain

structure within a deformed metal when heated above its recrystallization

temperature. This occurs during hot forging. |

|

Strain Hardening (Work Hardening) |

The increase in hardness and strength of a metal

caused by plastic deformation at temperatures below its recrystallization

point (i.e., during cold forging). |

|

Forging Laps |

A defect caused when a surface fold of

metal is forged into the surface of the part. Often a result of improper die

design or technique. |

|

Die Shift |

A defect where the two halves of the die

are misaligned, causing a mismatch at the parting line on the forging. |

|

Scale |

The layer of oxide that forms on the

surface of the metal when heated in the presence of air. It must be removed

to avoid being forged into the part surface. |

Category 6: Secondary Operations

|

Term |

Definition & Context |

|

Trimming |

The operation of removing the flash from

the forged part, typically done in a press with a trimming die while the part

is still hot. |

|

Heat Treatment |

A process of heating and cooling the

forging (e.g., annealing, normalizing, quenching & tempering) to achieve

the desired mechanical properties (strength, hardness, toughness). |

|

Shot Blasting |

Propelling a stream of abrasive material

(shot) at the forging to remove scale and clean the surface. |

|

Shot Peening |

A similar process to shot blasting, but

controlled to impart compressive stresses on the surface of the part,

improving its fatigue life. |

|

Coining |

A final precision forging operation

performed in a special die under high pressure to improve surface finish and

hold critical dimensions. |

|

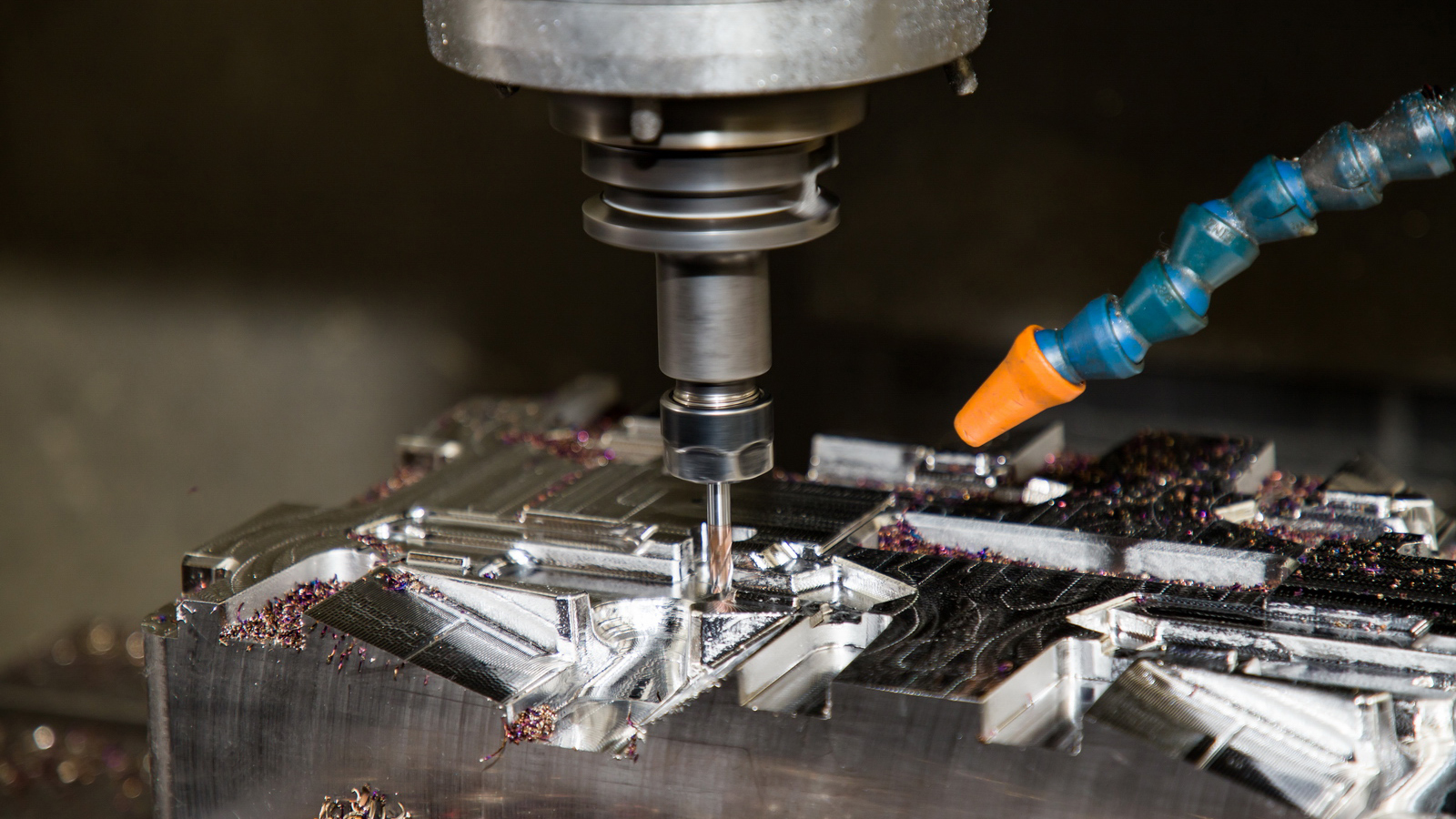

Machining |

Removing material from the forging (e.g.,

turning, drilling, milling) to achieve final dimensions and tolerances that

cannot be achieved by forging alone. |