Mastars summarizes five factors that affect the quality of die castings! In the process of die casting production, the excellent quality of die castings not only affects the delivery rate of customers, but also seriously affects the production cost of

die castings. Therefore, after years of practical experience, mastars summarized five factors affecting the quality of die castings.provide

rapid cnc services,

rapid cnc machining,

rapid prototyping services.It enjoys a high reputation in terms of stability while maintaining a dynamic, supportive and flexible spirit.

1. Die casting machine

Die casting machine is the basic key equipment of die casting production, the hardware to adjust and select the parameters of die casting company, and the core to obtain good die castings. Therefore, before designing the die casting die, we need to select the die casting machine according to the size, volume and process structure characteristics of the die casting, and the technical specifications and performance of the selected die casting machine should meet the technical requirements of the die casting.

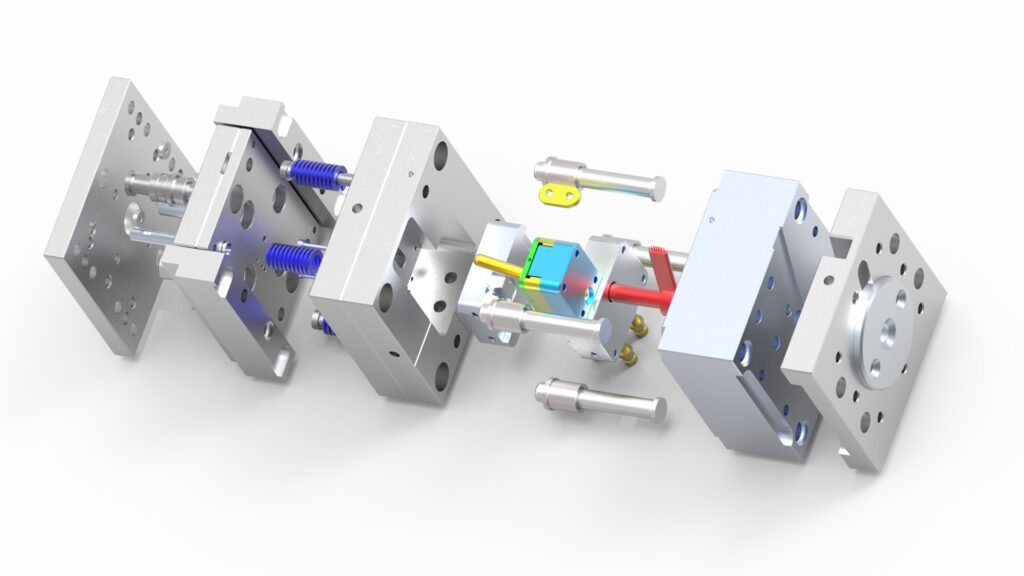

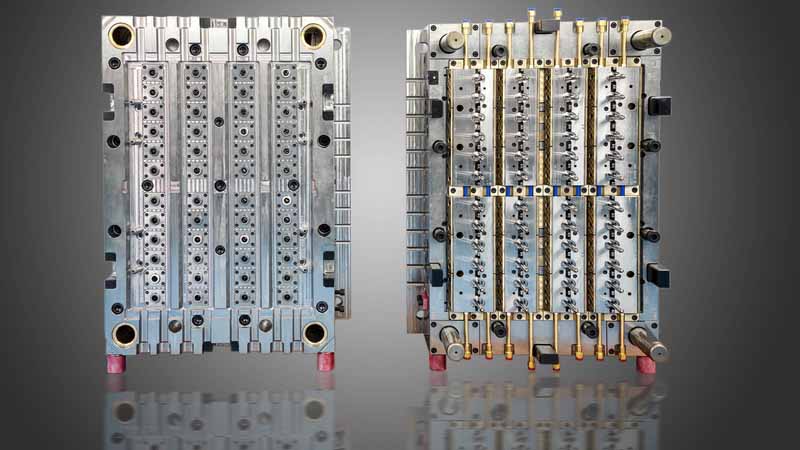

2. Die casting die

Die casting die is one of the important tools of die casting production, so to obtain good die castings, design reasonably according to the product structure to ensure the orderly progress of die casting production.

3. Selection of raw materials for die castings

In the production process, the selection of raw materials is also very important. The appropriate zinc alloy raw materials are reasonably selected for die casting production according to the product performance, so as to ensure the excellent product quality.

4. Die casting structure

Whether the die-casting structure is reasonable or not has a direct impact on the structure of the die-casting mold, the quality of the die-casting parts and the production cost. If the structural design of the die-casting parts is unreasonable, the drawing will not only lead to the complex structure of the die-casting mold, but also the forming quality can not be guaranteed.

5. Die casting process parameters

In the process of die-casting production, many factors work together. The main factors that favor the speaker are pressure, speed, temperature and time. All process factors restrict each other. Only by selecting, controlling and adjusting the process parameters to make them coordinate in a good state and meet the needs of die-casting production, can we produce qualified die-casting parts.

Because the die casting process has the advantages of good quality, high efficiency and excellent economic effect, it is widely used in various fields. Therefore, if you want to save production costs and make more good die castings, you can follow the above five elements summarized by mastars.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China