Aerospace sheet metal is critical for managing extreme temperatures and thermal stresses in spacecraft and aircraft. From re-entry heat exceeding 1,427°C to the 3,200°C inside rocket combustion chambers, materials face intense demands. Effective thermal design ensures safety, structural integrity, and longevity in these harsh conditions. Here's how:

Thermal management in aerospace isn't just about materials - it's about combining smart design, precise manufacturing, and regulatory compliance to ensure performance and safety.

Getting a handle on how heat moves through sheet metal is a must for managing thermal challenges in aerospace. The extreme conditions these vehicles face make understanding heat transfer not just important but essential. These principles form the backbone of the design strategies explored in later sections.

In aerospace sheet metal, heat travels through three main mechanisms: conduction, convection, and radiation.

The shape and size of components play a big role in how effectively they manage heat. A larger surface area means more interaction with the surrounding environment, which translates to better cooling. Newton's Law of Cooling highlights this link between surface area and heat dissipation.

Interestingly, surface characteristics like roughness can also make a difference. Rougher surfaces improve thermal emissivity, allowing heat to dissipate up to 2.5 times more effectively. Techniques like chemical coarsening or mechanical shot peening can create this roughness, reducing light reflection and increasing the absorption of infrared radiation.

Selecting the right material for aerospace sheet metal thermal applications is a balancing act between thermal performance, weight, cost, and environmental demands. The material chosen plays a pivotal role in managing heat effectively, especially under extreme operating conditions. This decision has a direct influence on the thermal design strategies that follow.

Aluminium alloys are a go-to choice in aerospace because of their excellent thermal conductivity and low density (approximately 2.7 g/cm³). Alloys like 6061-T6 are reliable for many applications, while stronger options like 2024-T3 are used for more demanding conditions.

Copper alloys stand out for their exceptional thermal conductivity, making them highly efficient for heat dissipation. However, their higher density can be a drawback in weight-sensitive designs. Beryllium copper alloys offer a balance of good thermal performance and mechanical strength, but they require careful handling due to health and safety considerations.

Stainless steel is the material of choice when corrosion resistance is as critical as thermal performance. For instance, 316L stainless steel has lower thermal conductivity compared to aluminium or copper but compensates with outstanding durability and resistance to harsh environmental conditions. This makes it ideal for external components exposed to thermal cycling and aggressive environments.

Titanium alloys are a premium option for thermal management in aerospace. Alloys like Ti-6Al-4V offer moderate thermal conductivity but are prized for their strength-to-weight ratio and corrosion resistance, making them suitable for high-performance applications.

Weight considerations are crucial in aerospace design, where every gram can impact fuel efficiency and payload capacity. Engineers often evaluate materials based on their thermal conductivity relative to weight rather than focusing solely on absolute conductivity.

Environmental compatibility ensures materials can maintain their thermal properties even under extreme temperature fluctuations. Resistance to oxidation and other environmental challenges is key for ensuring long-term performance.

Cost factors go beyond the initial price of the material. While some materials may offer superior thermal properties, they can lead to higher lifecycle costs due to added weight or more complex fabrication processes, such as specialised welding or heat treatments.

Corrosion resistance is essential for preserving thermal performance over time. Corrosion can degrade a material's ability to transfer heat, so choosing a corrosion-resistant material is critical for applications where durability and longevity are priorities.

Manufacturing compatibility also plays a significant role. Some materials respond better to surface treatments that enhance thermal emissivity, while others are easier to form into complex shapes that improve heat transfer. Additionally, the material's compatibility with joining techniques like welding or brazing is vital when designing integrated thermal systems.

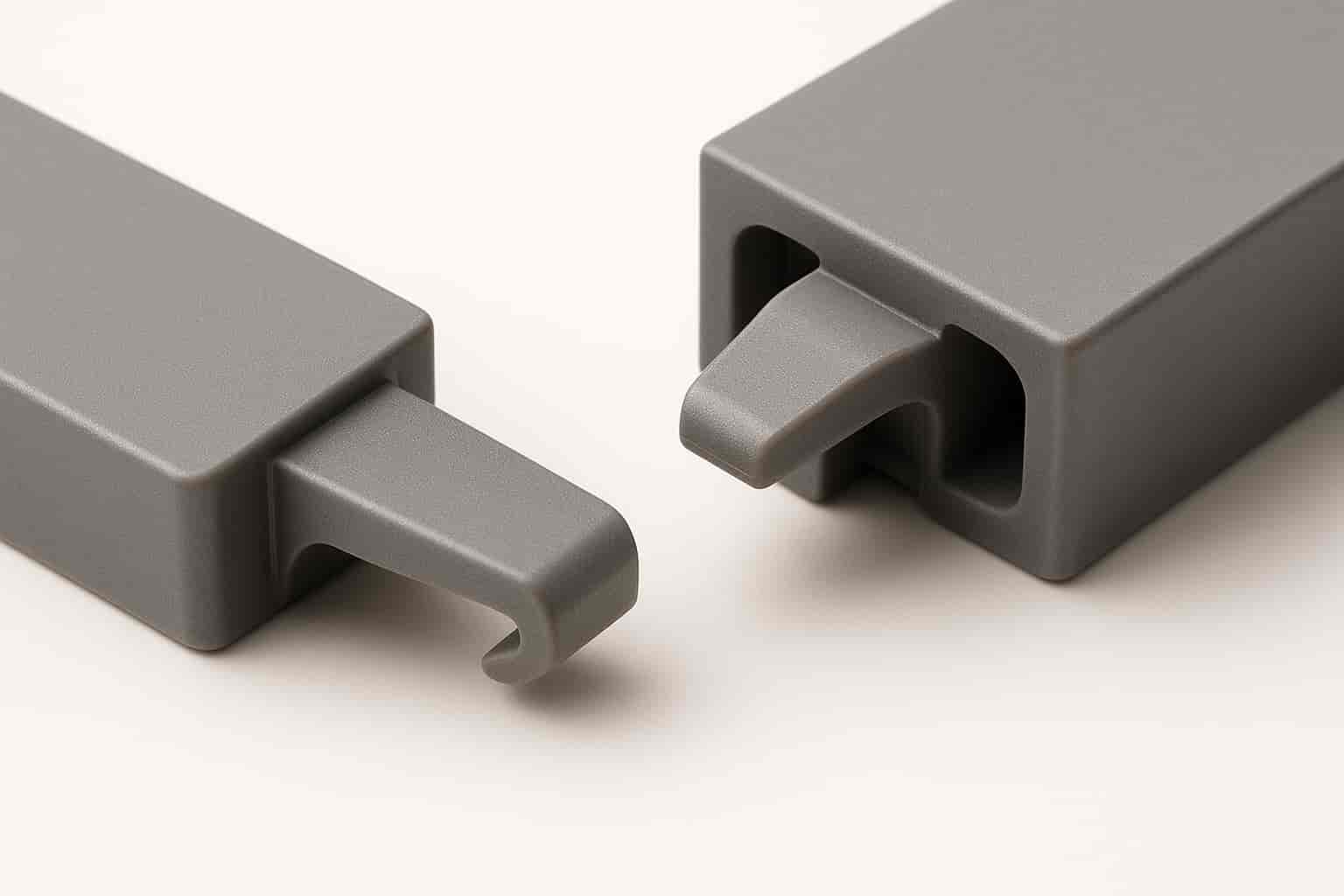

Managing heat in aerospace sheet metal designs requires a combination of smart geometry, advanced manufacturing techniques, and structural features. These approaches work together to optimise heat transfer and maintain performance, building on the material and geometric principles already discussed.

Fins and heat sinks play a crucial role in enhancing heat dissipation by increasing surface area. However, spacing is key - fins placed too close can restrict airflow, while overly spaced fins may not fully utilise the available surface area. The ideal spacing depends on factors like operating environment and airflow conditions.

Ventilation openings should be carefully positioned to take advantage of natural convection. For example, placing inlets at the bottom and exhaust vents at the top leverages upward-moving warm air currents. These openings must be sized and placed to balance airflow, structural integrity, and electromagnetic interference requirements, which are particularly critical in aerospace designs.

Airflow channels can be incorporated by strategically bending and joining sheet metal. These channels guide cooling air to critical components, maintaining airflow velocity and minimising pressure drops to ensure efficient cooling.

Thermal bridges, such as straps, can connect hotter areas to cooler regions without adding unnecessary weight or compromising structural integrity. These elements help redistribute heat effectively while keeping the design lightweight.

Surface geometry modifications, like dimpling, corrugating, or texturing, can significantly improve heat dissipation by increasing the effective surface area. These techniques enhance forced convection cooling compared to smooth surfaces.

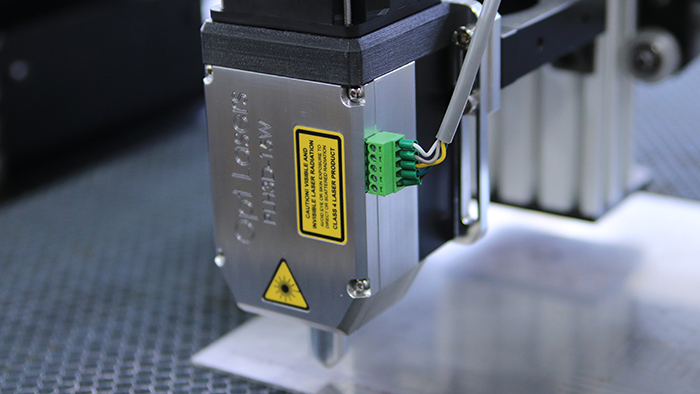

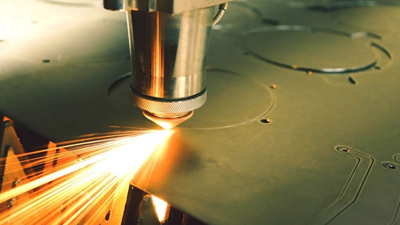

Precision laser cutting enables the creation of intricate cooling patterns and vents while minimising heat-affected zones. This is especially useful for forming complex fin configurations or micro-perforations for controlled airflow.

CNC bending and forming ensures consistent three-dimensional geometries for heat sinks. Advanced CNC equipment delivers precise bend angles and radii, optimising airflow and heat transfer while maintaining uniformity across production runs.

Robotic welding provides strong, thermally conductive joints and ensures hermetic seals in pressurised cooling systems. This method also maintains excellent thermal contact between components, enhancing overall system performance.

Hydroforming and stretch forming are ideal for creating smooth, curved surfaces that reduce turbulence and pressure losses in cooling ducts. These techniques are particularly useful for producing large heat exchanger surfaces or aerodynamic cooling channels.

Friction stir welding and brazing improve the thermal conductivity of joints by reducing heat-affected zones. These methods can also refine the grain structure of the joint, eliminating porosity and enhancing thermal performance.

Partnering with experienced prototyping services like Mastars can validate and refine these design concepts. Their rapid CNC machining and prototyping capabilities accelerate the transition from design to production, ensuring thermal performance strategies are effectively implemented.

Surface finishing also plays a role in thermal management. Controlling surface roughness can improve heat transfer while meeting other requirements like corrosion resistance, cleanability, and electromagnetic compatibility.

In aerospace applications, surface treatments do more than just protect components from the environment - they also play a critical role in managing thermal performance. The right finish can help dissipate heat, improve emissivity, and extend the life of components operating in harsh conditions. Below, we’ll explore key surface treatments and how to choose finishes that optimise thermal control in aerospace environments.

Different surface finishes bring unique thermal and protective benefits. Here’s how some of the most commonly used treatments perform:

Selecting the right surface finish depends on the specific demands of the application. Environmental factors like UV exposure, extreme temperatures, and salt spray require finishes that can form strong protective barriers and withstand harsh conditions.

Spacecraft components face even tougher challenges, such as outgassing, atomic oxygen exposure, and extreme thermal cycling. In these cases, low-outgassing finishes are critical to avoid contaminating sensitive systems, while high-emissivity coatings help with radiative cooling in the vacuum of space.

Thermal performance goals also influence the choice of finish. For instance, heat sinks benefit from high-emissivity coatings - like certain anodising treatments or specialised thermal finishes - that enhance radiative heat transfer. On the other hand, components needing thermal insulation may require coatings that limit heat conduction.

Durability and functionality are equally important. Finishes must maintain low contact resistance while offering environmental protection. Conductive platings or thermal interface materials often strike this balance. Additionally, finishes need to comply with industry standards for thickness, adhesion, and resistance to environmental factors. They must also integrate seamlessly with manufacturing processes like welding, brazing, or assembly to avoid contamination or mechanical issues.

In aerospace, the right surface treatment isn’t just an afterthought - it’s a critical factor in meeting thermal performance and durability requirements.

The aerospace industry operates under strict standards and regulations to ensure thermal designs can handle the intense conditions of flight. These rules are in place to guarantee that sheet metal components maintain their reliability and performance, even in the most extreme environments. National and international guidelines require rigorous testing, comprehensive documentation, and continuous evaluation to meet these high demands.

Thermal management in aerospace is governed by a range of quality and environmental standards. These standards dictate everything from the materials used to the testing protocols and lifecycle assessments. The goal? To create thermal systems that manage heat effectively and safely throughout the lifespan of a component.

Compliance with aerospace regulations is non-negotiable. This includes adhering to requirements for material certification, system safety, and environmental testing. Manufacturers perform detailed thermal stress tests - such as thermal cycling and shock tests - to ensure sheet metal can endure sudden temperature changes and harsh operating conditions. Thorough documentation of these tests and certifications serves as proof of compliance and reliability.

Incorporating these regulatory measures early in the design process is key to developing effective thermal management strategies for aerospace sheet metal components.

The aerospace industry is making strides in thermal management, driven by advancements in materials, digital design tools, and manufacturing techniques. These innovations are transforming how engineers tackle heat dissipation challenges in sheet metal components, paving the way for lighter, more efficient, and reliable thermal solutions for modern aircraft and spacecraft.

The development of advanced materials like aluminium-lithium alloys and hybrid metal-composite structures is revolutionising thermal management. These materials not only offer improved thermal conductivity but also help reduce weight. Their ability to perform consistently under high temperatures makes them particularly suitable for areas near engines and electronic systems.

Digital design tools have also become indispensable in aerospace thermal engineering. These tools simulate complex heat transfer scenarios with remarkable accuracy, reducing the reliance on physical prototypes. By optimising sheet metal geometries early in the design process, engineers can enhance thermal performance before manufacturing even begins.

Artificial intelligence is further streamlining the design process. Machine learning algorithms can predict the best configurations for fins and surface treatments based on specific operating conditions, cutting down on design iterations and improving overall efficiency.

Additive manufacturing, or 3D printing, is another game-changer. This technology allows for the creation of heat exchangers with intricate internal cooling channels that outperform traditional designs. These advancements not only improve heat transfer but also open up new possibilities for collaboration with expert manufacturers.

Given the complexity of aerospace thermal design, working with experienced manufacturing partners is crucial. Manufacturers who understand both the technical challenges and regulatory demands of the aerospace industry can significantly enhance the design process. Mastars, a leading OEM manufacturing and product development firm, exemplifies this expertise with its comprehensive approach to prototyping, tooling, and assembly.

Mastars' advanced prototyping capabilities enable rapid testing and validation of thermal designs. This quick turnaround allows engineers to confirm performance before moving to large-scale production, ensuring components meet both thermal and structural requirements.

Their manufacturing expertise supports the creation of intricate thermal management components with the precise tolerances needed for effective heat transfer. By blending traditional manufacturing methods with cutting-edge techniques, Mastars ensures the final products are both efficient and reliable.

What sets Mastars apart is their integrated approach. By managing prototyping, tooling, and assembly in-house, they streamline the transition from prototype to production. This not only reduces costs and timelines but also preserves the integrity of the original design, making them a trusted partner in crafting next-generation aerospace thermal solutions.

With these advancements in materials, tools, and manufacturing processes, the future of aerospace thermal design looks promising, offering solutions that meet the rigorous demands of aviation and space exploration.

When it comes to thermal design in aerospace sheet metal, success lies in balancing performance, weight, and compliance with industry standards. Here’s a breakdown of the most important strategies:

Selecting the right material is critical. Aluminium alloys like 6061-T6 and 2024-T3 offer a great mix of thermal conductivity and strength-to-weight efficiency, making them ideal for many applications. On the other hand, titanium alloys are the go-to choice for handling extreme temperatures.

Geometry plays a big role in optimising thermal performance. Features like fins, ribs, and perforations can increase surface area, improving heat dissipation. At the same time, the thickness of the sheet must be carefully managed to enhance heat conduction without adding unnecessary weight or jeopardising structural integrity.

Surface treatments also make a significant difference. For example, anodising aluminium not only boosts corrosion resistance but also improves emissivity, enhancing the material's ability to transfer heat through radiation. Hard anodising takes this a step further by combining thermal efficiency with durability.

Precision in manufacturing is non-negotiable. Tight tolerances ensure effective heat transfer pathways, reducing the risk of thermal bottlenecks or hotspots. Rigorous quality control during production is equally important to eliminate potential defects that could compromise reliability.

Regulatory compliance is another cornerstone of effective thermal design. Meeting strict aerospace standards requires thorough documentation and extensive testing to ensure every component performs as expected.

Finally, collaborating with experienced manufacturers, such as Mastars, can streamline the process from design to production. These partnerships help validate thermal performance quickly and ensure the final product meets all necessary requirements.

When choosing materials for managing heat in aerospace sheet metal design, high thermal conductivity is a key factor. This ensures heat is effectively dispersed, preventing potential overheating issues. The materials also need to endure the extreme temperatures typical in aerospace settings while maintaining their structural strength. On top of that, they must resist corrosion and handle mechanical stresses to perform reliably over time.

Some of the most commonly used materials for these purposes are titanium, aluminium alloys, ceramics, and metal matrix composites. These materials strike a balance between being lightweight and tough, making them well-suited for the demanding conditions of aerospace applications.

Surface treatments are key to improving thermal performance in aerospace sheet metal design. These treatments, often involving specialised coatings, serve as thermal barriers that help reflect or disperse heat, safeguarding the materials beneath.

Techniques like thermal spray coatings and chem-films are widely used to manage heat transfer more effectively, minimise thermal stress, and increase component longevity. Beyond durability, these treatments boost thermal insulation and heat dissipation, ensuring aerospace parts function reliably even in the harshest conditions.

When it comes to aerospace sheet metal components, fins and airflow channels are indispensable for managing heat effectively. Fins work by boosting the surface area that comes into contact with air, which improves convective heat transfer. This helps heat escape more efficiently. Plus, fins disturb the airflow boundary layers, creating turbulence that further enhances heat transfer.

On the other hand, airflow channels are carefully designed to guide air around critical parts, ensuring heat is removed efficiently and thermal stability is maintained. These design elements are especially important in aerospace, where lightweight materials and precise temperature control are essential for both safety and high performance.