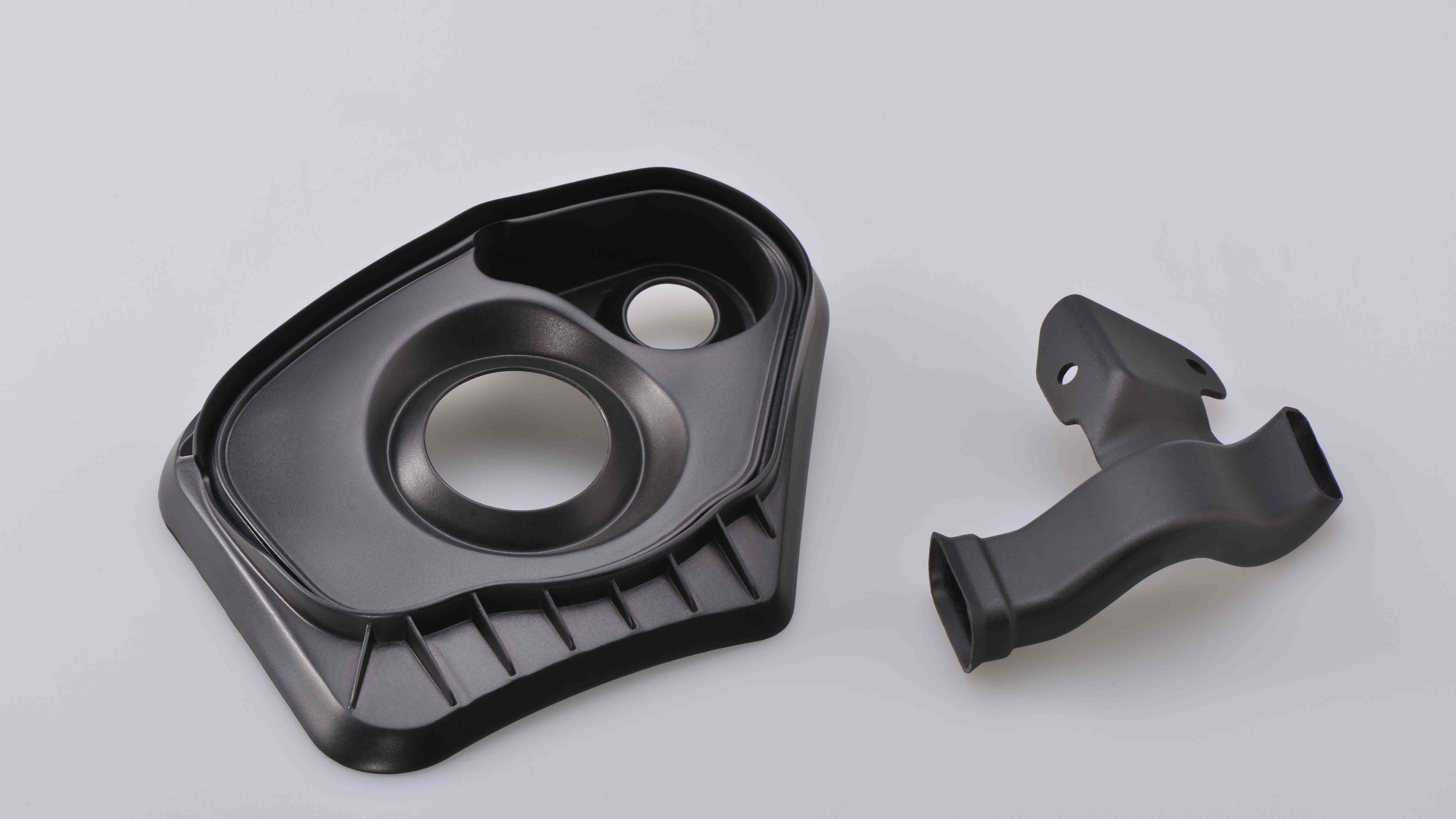

Mastars as a

metal prototype maker, provides

rapid sheet metal prototyping,

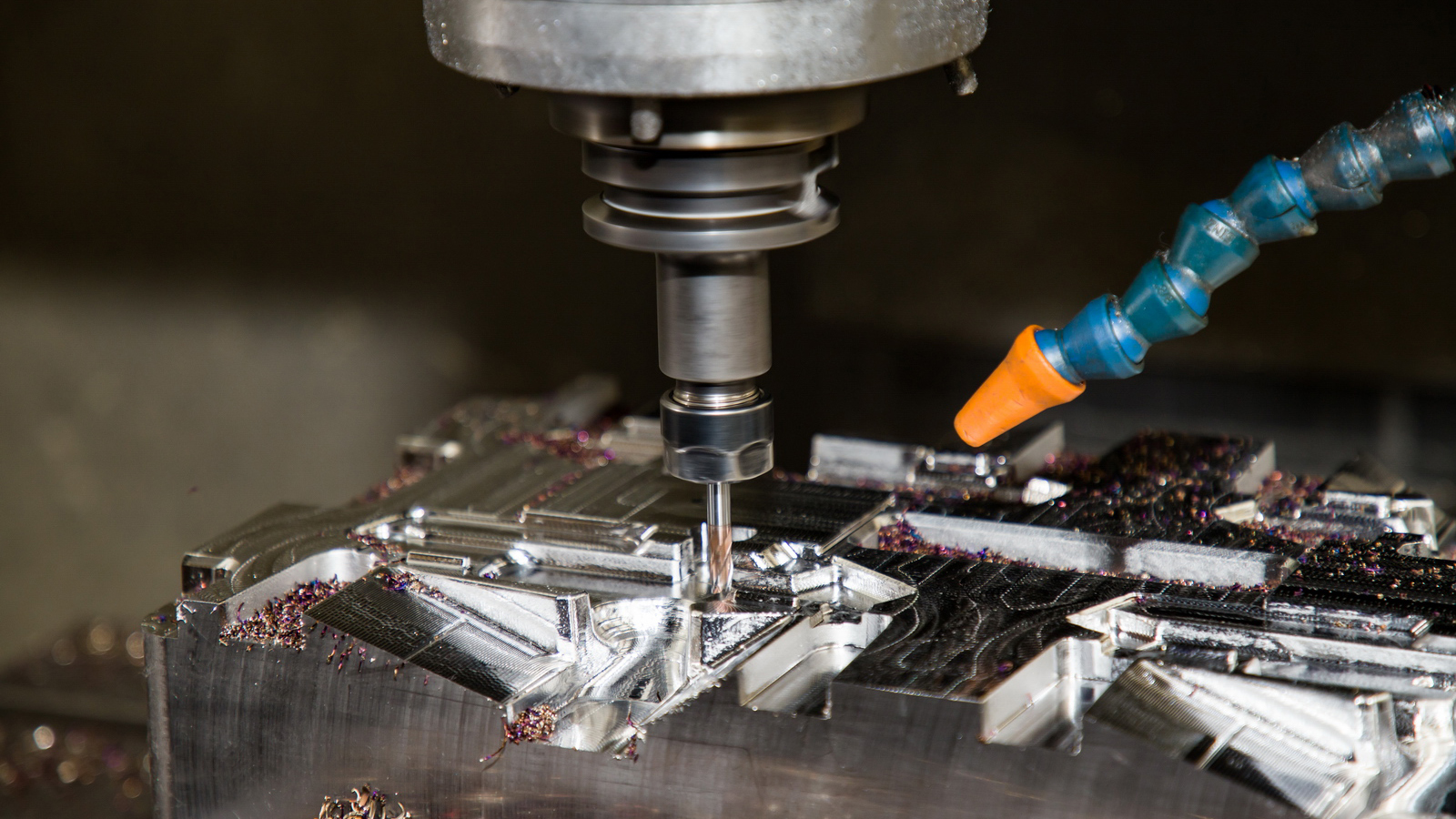

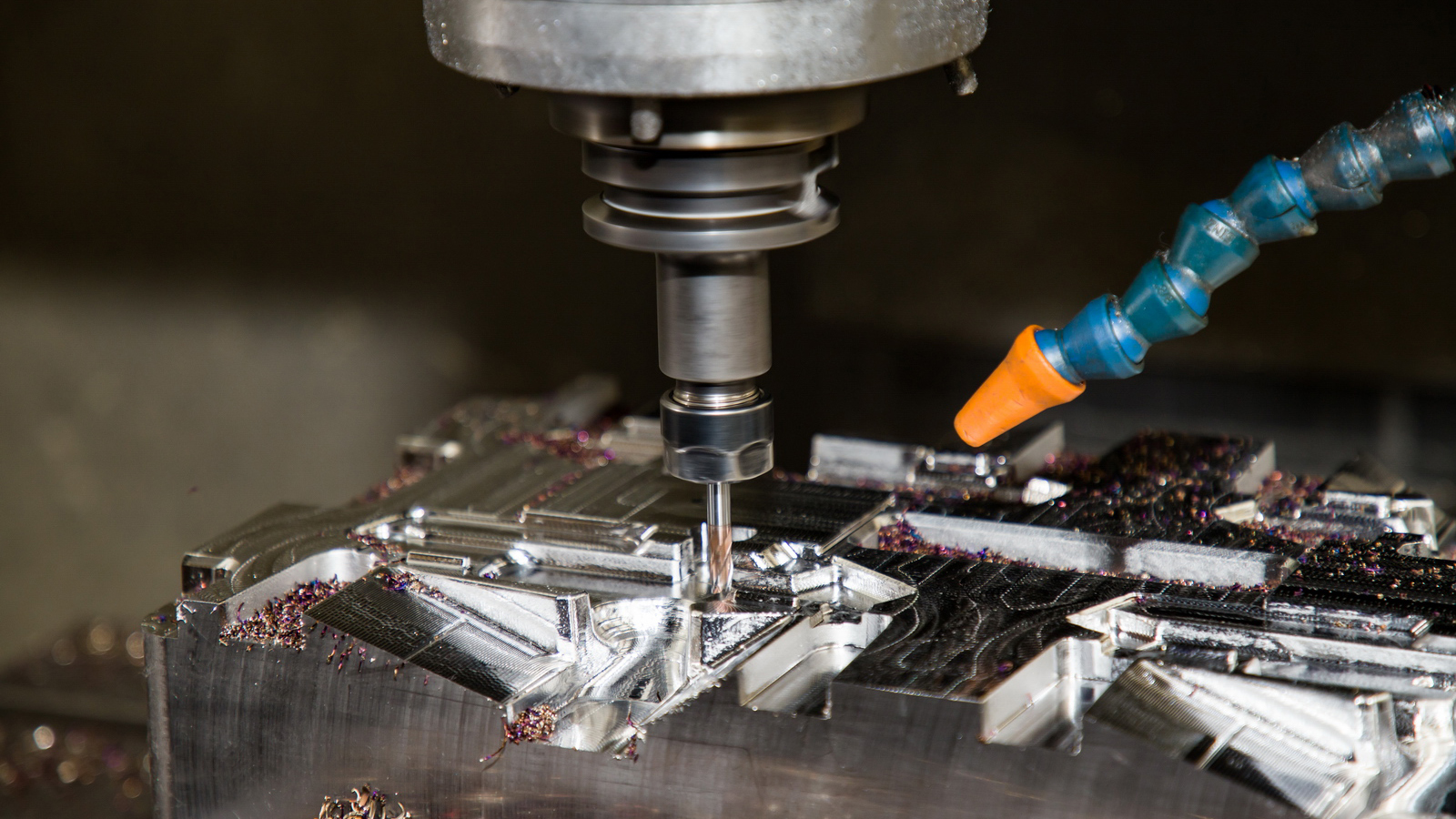

rapid CNC service.rapid prototyping.CNC machining is to compile the CNC machining program of parts according to the original conditions such as part drawings and process requirements, and input it into the CNC system of CNC machine tool, so as to control the relative movement of cutting tool and workpiece in CNC machine tool, so as to complete the machining of parts.

Common CNC machining methods

1. Plane hole system parts

Commonly used point and line control CNC machine tools are used for machining. When selecting machining methods, two principles of machining accuracy and efficiency are mainly considered, that is, what machining method can ensure the machining accuracy of parts and what machining method can improve the machining efficiency of parts.

2. Rotating parts

Two principles of machining efficiency and tool tip strength are mainly considered when machining with CNC lathe or CNC grinder;

(1) Considering the machining efficiency, when machining on the lathe, the machining allowance is usually large, and the rough machining route must be reasonably arranged to improve the machining efficiency; The actual programming is generally not high, and the comparison of circular instructions is adopted; A better method is to remove the material as soon as possible with a rough car and then finish the car;

(2) Consider the strength of the tool tip; The strength of the cutting tool used in the machining of small grooves must be determined by the strength of the cutting tool used in the CNC lathe;

3. Planar profile part

Commonly used CNC milling machine processing; When selecting the processing method, the two principles of processing accuracy and processing efficiency shall be mainly considered. When determining the processing method, attention shall be paid to:

(1) Control of cutting in and cutting direction of cutting tool, milling plane contour, cutting tool cuts in along the extension line of cutting variable and cuts out along the extension line of cutting edge, and the surface contour of workpiece is smooth; If the cutting tool does not cut in and out along the extension line of the cutting edge, the cutting trace of the cutting tool will be left on the surface contour of the workpiece;

4. Solid contour parts

Commonly used multi axis CNC machine tools; When selecting the processing method, the two principles of processing accuracy and processing efficiency shall be mainly considered. When determining the processing method, the following shall be considered:

(1) The strength and surface quality of the workpiece, and the parts with weak strength on the three-dimensional contour parts are often difficult to bear the cutting amount during rough machining. At the same time, corresponding workpiece measures shall be taken for the parts with high surface quality requirements;

(2) Interpolation function of machine tool.

CNC machining features

1. Strong adaptability; During CNC machining, the CNC program compiled according to the requirements of parts is used to control various actions of the equipment actuator. When the requirements of CNC workpiece are changed, as long as the CNC program software is changed without changing the hardware of mechanical part and control part, it can adapt to the new work requirements. Therefore, the production preparation cycle is short, which is conducive to the renewal of mechanical products.

2. High precision and stable quality; CNC machining itself has high machining accuracy, and software can also be used for accuracy correction and compensation; CNC machine tools process parts automatically according to CNC programs, which can avoid human errors; Therefore, CNC machining can obtain higher machining accuracy than conventional machining; In particular, the consistency of the production of the same batch of parts is improved, and the product quality is stable;

3. High production efficiency; Large amount of motion can be adopted on NC equipment, which effectively saves motion man hours; It also has the functions of automatic speed change, automatic tool change and other auxiliary operation automation, and there is no need for inspection and measurement between processes, so the auxiliary time is greatly shortened;

4. Can complete the machining of complex profile; The machining of many complex curves and surfaces cannot be realized by ordinary machine tools, but CNC machining can be completed completely;

5. Reduce labor intensity and improve working conditions; Because CNC machining is completed automatically, many actions do not need to be carried out by the operator, so the working conditions and labor intensity are greatly improved;

6. It is conducive to production management. The adoption of CNC machining is conducive to the development of computer control and management of production, and creates conditions for the realization of manufacturing and production management automation.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China