Mastars is a prototype company in China. We employ proven prototype technologies(rapid CNC machining, rapid sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping etc.)

Many people don't know what kind of prototype POM prototype is. Now many product R & D will use prototype models to test the feasibility of some product data, but there are many materials for making prototypes, and POM is also a kind of material for making prototypes. Now let's take a look at the specific introduction of POM prototype.

What is POM prototype?

Polyformaldehyde, also known as acetal resin. Full name: polyoxymethylene resin, referred to as polyoxymethylene, thermoplastic crystalline polymer. Polyoxymethylene thermoplastic crystalline polymer, known as "super steel" or "saigang", also known as polyoxymethylene, is abbreviated as POM. Therefore, POM prototype can also be called saigang prototype model. Usually, the polymer obtained by formaldehyde polymerization has low degree of polymerization and is easy to depolymerize by heating. It can be used as raw material of organic chemical industry and synthetic resin, and also as pharmaceutical fumigant.

Advantages and disadvantages of POM prototype

1. Advantages of POM prototype

1) POM prototype has good performance and characteristics. Firstly, it has excellent mechanical properties, tensile strength, impact strength, creep resistance, wear resistance and lubricity. It has good melting resistance, oil resistance and vulnerability resistance. It is commonly used in structural parts with high strength requirements such as gears.

2) The electrical insulation of POM prototype is good, which is almost unaffected by temperature and humidity; Dielectric constant and dielectric loss vary little in a wide range of temperature, humidity and frequency; Excellent arc resistance and can be maintained at high temperature.

2. Disadvantages of POM prototype

It is not resistant to strong acids, especially mineral acids, ultraviolet rays, self extinguishing, near fire and impact.

Main applications of POM prototype

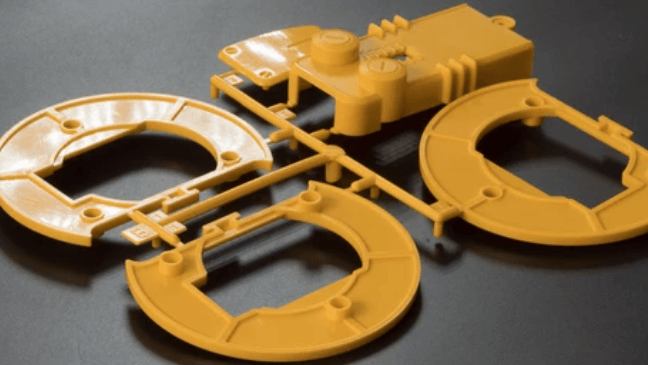

1. Prototype processing of household appliances

Because the characteristics are close to metal, if POM materials are used for prototype processing, the cost will be relatively higher than most plastic materials, and the processing is difficult. Therefore, if you make a prototype model, the price of the workpiece will be relatively higher. Therefore, designers only use this material on some parts. In order to save development and production costs, POM will not be used to prototype all parts.

2. The prototype model made by POM has good electrical insulation and is hardly affected by temperature and humidity; Dielectric constant and dielectric loss vary little in a wide range of temperature, humidity and frequency; Excellent arc resistance and can be maintained at high temperature. It is mainly used for gears, bearings, auto parts, machine tools, instrument internals and other products that play the role of a skeleton. It can replace most non-ferrous metals, automobiles, machine tools, instrument internals, bearings, fasteners, gears, spring sheets, pipes, conveyor belt accessories, electric water cookers, pump shells, drain devices, faucets, etc.

3. Electronic and electrical appliances: washing machine, juice machine parts, timer components, etc.

4. Automobile: handlebar parts, electric window parts, etc.

5. Industrial parts: mechanical parts, gears, handles, toys, screws, etc.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China