Mastars is a metal prototype maker providing rapid cnc services, focusing on mold design, injection molding, silk screen printing, oil injection and finished product assembly, and providing all-round plastic parts and finished product solutions.Injection molding service one-stop service. get quote within 24 hours We Provide Custom Molding for 1 to 100,0000+ Injection-molded Parts

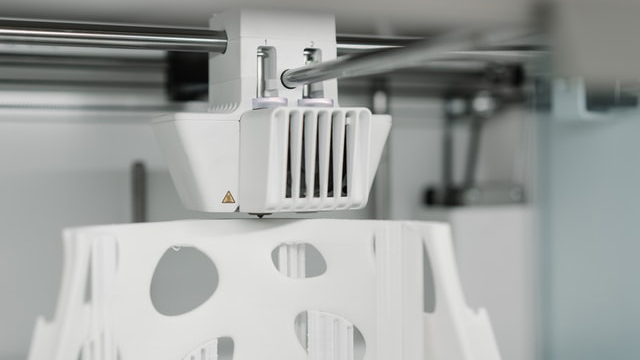

Injection molding: also known as injection molding, its principle is to add granular or powdery raw materials into the hopper of the injection machine. The raw materials are heated and melted into a flowing state. Driven by the screw or piston of the injection machine, they enter the mold cavity through the nozzle and the mold pouring system, and harden and shape in the mold cavity.

Factors affecting injection molding quality: injection pressure, injection time, injection temperature

Advantages:

1. Short forming cycle, high production efficiency and easy automation

2. Capable of forming plastic parts with complex shapes, accurate dimensions and metal or non-metal inserts

3. Stable product quality

4. Wide application range

Disadvantages:

1. High price of injection molding equipment

2. Complex injection mold structure

3. High production cost, long production cycle, not suitable for single piece and small batch production of plastic parts

Application:

Among industrial products, injection molded products include kitchen supplies (garbage cans, bowls, buckets, pots, tableware and various containers), enclosures of electrical equipment (hair dryers, vacuum cleaners, food mixers, etc.), toys and games, various products of the automotive industry, and parts of many other products.

Insert injection molding:

it refers to the molding method that the pre prepared inserts of different materials are filled into the mold and then injected with resin, and the molten materials are bonded and solidified with the inserts to form an integrated product.

Process flow:

In the insert molding process, the injection molding machine is usually only a part of the whole system. The inserts usually need to be oriented first, which can be accomplished by using a vibrating table. The insert is then placed into the mold by the robotic end tool (eoat), which can usually enter the mold with the help of a pre positioning device. When it comes to the finished product stage, ejection positioning is the most important step, and the repeatability of the mold opening action of the injection molding machine is very important here. After the insert is closed into the mold, it is fixed in a vacuum state or mechanically (e.g. with a slider). While the insert is inserted, the last finished part is ejected.

Technical features:

1. The pre forming combination of multiple inserts makes the post engineering of product unit combination more reasonable.

2. The combination of resin's formability, flexibility and metal's rigidity, strength and heat resistance can be used to make complex and exquisite metal plastic integrated products.

3. In particular, the combination of resin insulation and metal conductivity is used to make the molded products meet the basic functions of electrical products.

4. For the rigid molded products and the bending elastic molded products on the rubber sealing base plate, after the integrated products are made by injection molding on the substrate, the complex operation of arranging the sealing rings can be omitted, making the automatic combination of subsequent processes easier.

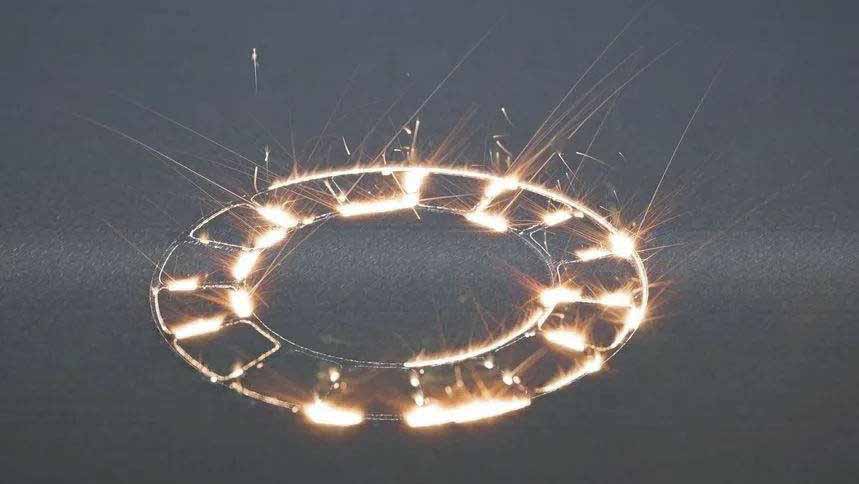

Nano injection molding

It is a method of combining metal and plastic with nanotechnology. First, the metal surface is nano treated, and then the plastic is directly injected into the metal surface, so that the metal and plastic can be formed as a whole.

Nano molding technology can be divided into two types of processes according to the location of Plastics:

1. Plastic is one-piece molding of non appearance surface

2. Plastic as an integral part of the appearance

Process characteristics:

1. The products have metal appearance and texture,

2. The simplified design of product mechanism makes the product lighter, thinner, shorter and smaller, and more cost-effective than CNC processing.

3. Reduce production cost and high bonding strength, and significantly reduce the utilization rate of relevant consumables

Applicable metal and resin materials:

1. Aluminum, magnesium, copper, stainless steel, titanium, iron, galvanized sheet, brass;

2. Aluminum alloy has strong adaptability, including 1000 to 7000 series;

3. Resins include PPS, PBT, PA6, PA66 and PPA;

4. PPS has a particularly strong adhesive strength (3000n/c ㎡).

Application:

Mobile phone shell, laptop shell, etc

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China