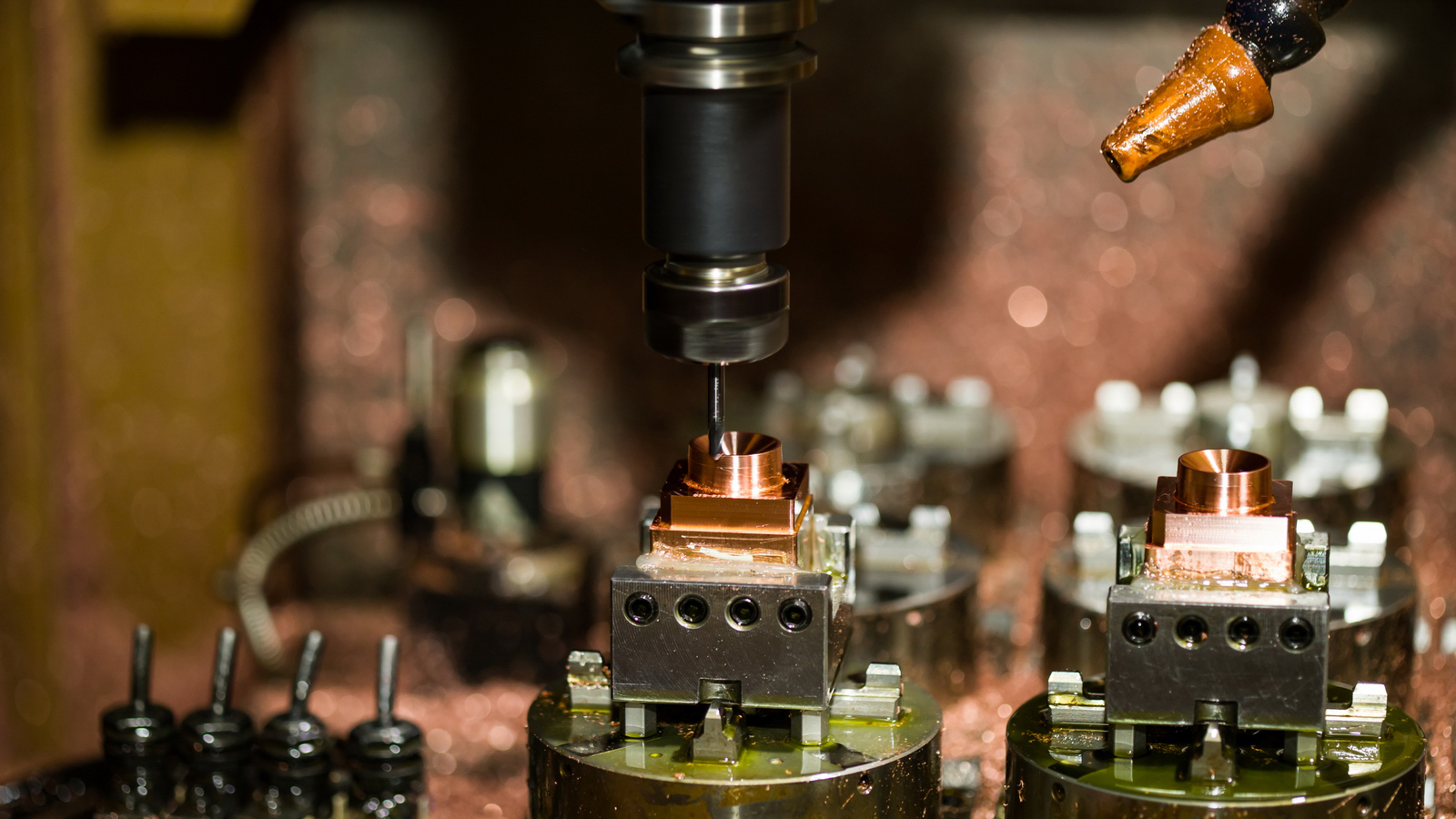

As a manufacturer of modern precision mechanical parts, mastars takes CNC processing as the core process, has physical factories and testing equipment, and integrates supporting manufacturing resources such as rapid prototyping, mold and post-treatment to provide customers with rapid proofing, mass production, manufacturing and trial assembly, so as to truly achieve a one-stop service that saves worry and effort; The enterprise has imported precision machining equipment such as computer gongs, milling machines, lathes and grinders, as well as a technical team with rich experience in non-standard production.

The burr produced in the process of machining and manufacturing of mechanical parts may have an adverse impact on the accuracy, performance and even the whole assembly system, and then affect the overall quality of the product; Therefore, in recent years, various industries pay more and more attention to burr removal. In this issue, mastars tells you in detail the importance of deburring hardware parts

Influence of burr on products

Due to the existence of burrs, the parts may not reach the fitting position. If the fitting position is reached, the coarser the fitting position is, the greater the pressure per unit area and the easier the surface is to wear;

Impact on the corrosion resistance of parts and the whole machine: after the surface treatment of parts, the burr will be knocked off during assembly, which will scratch the surface of other parts. At the same time, the exposed surface without surface protection will be formed on the surface where the burr falls off. Under humid climate conditions, these surfaces are most prone to rust and mildew, which will affect the corrosion resistance of the whole machine and leave potential quality hazards to the products.

Influence of burr on subsequent process and other processes

(1) If the burr is too large, the machining allowance will be uneven during finishing, resulting in scrap;

(2) If there are burrs on the finish datum, the datum is not easy to coincide with the positioning datum, resulting in unqualified machining dimensions;

(3) In the surface treatment process, the coating metal will first gather at the tip of the burr to produce unqualified products;

(4) Burr is the main factor that is most likely to cause bonding in the process of heat treatment. Burr is often the main reason for damaging interlayer insulation, which will lead to the significant decrease of AC magnetism of alloy. Therefore, burr must be removed before heat treatment of some special materials.

Importance of deburring

1. Prevent and avoid the existence of burrs from affecting the positioning and tightening of mechanical parts and reducing the machining accuracy;

2. Prevent and avoid the deviation of monitoring data due to the existence of burrs, increase the scrap rate of workpieces, and endanger the safety of operators;

3. Eliminate wear and failure caused by burr or falling off of mechanical parts during use;

4. When mechanical parts without burrs are coated and painted, the adhesion will increase, which can make the coating have uniform texture, good appearance quality, smooth and tidy, and the coating is firm and durable;

5. Mechanical parts with burrs are easy to produce cracks and reduce the fatigue strength of parts. Deburring of parts under load or parts running at high speed can not be ignored.

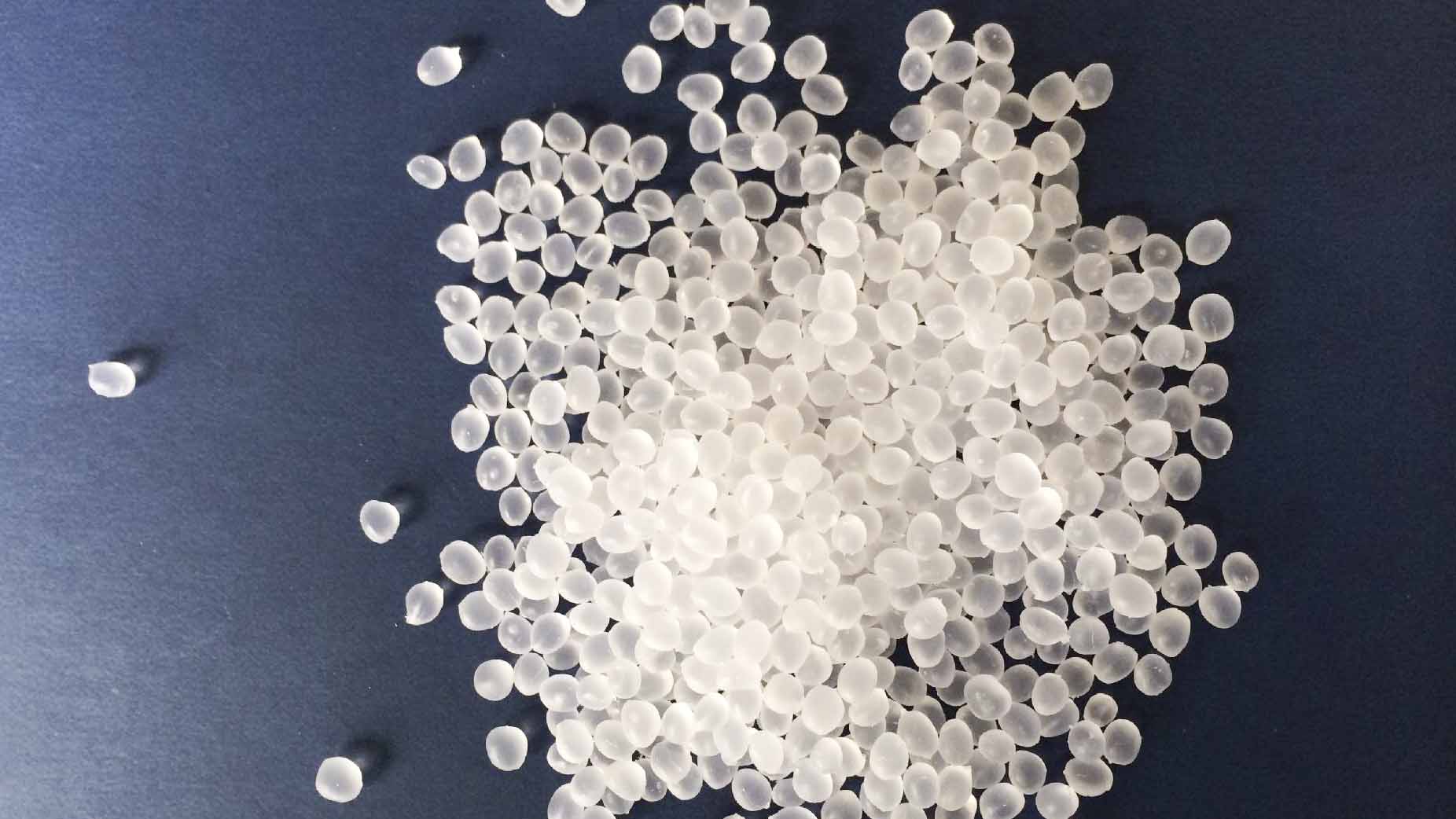

Deburring method

1. Electrolytic deburring

An electrochemical machining method for removing burrs of metal parts by electrolysis; Electrolytic deburring is suitable for deburring hidden parts, cross holes or parts with complex shapes. It has high production efficiency, and the deburring time generally takes only a few seconds to tens of seconds;

2. Ultrasonic deburring

Ultrasonic deburring is to use the instantaneous impact force of hundreds of atmospheres produced by "cavitation phenomenon" to remove the burrs attached to the parts; Ultrasonic deburring is not used for all burrs. It is mainly aimed at some micro burrs. Generally, if the burrs need to be observed with a microscope, you can try the ultrasonic method to remove them

3. Chemical deburring

Using the principle of chemical reaction, the deburring operation of parts made of metal materials can be completed automatically and selectively; It can be widely used for deburring the pump body, valve body, connecting rod, plunger needle valve and other parts made of different metal materials, such as pneumatic hydraulic pressure, engineering machinery, oil nozzle oil pump, automobile, engine and so on; It is applicable to parts that are difficult to remove burr and after heat treatment.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China