Commonly Used Injection Molding Materials You Can Choose

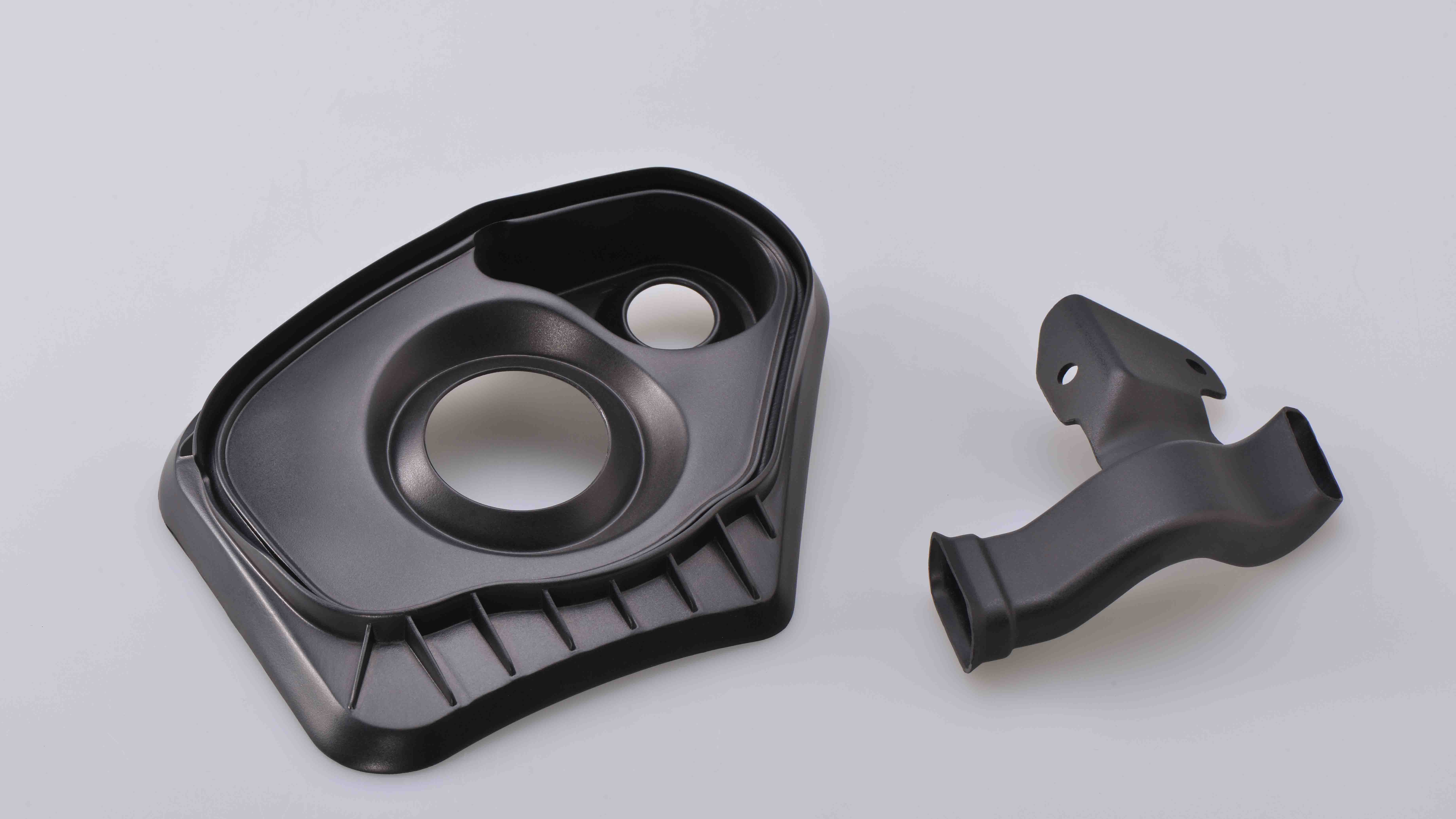

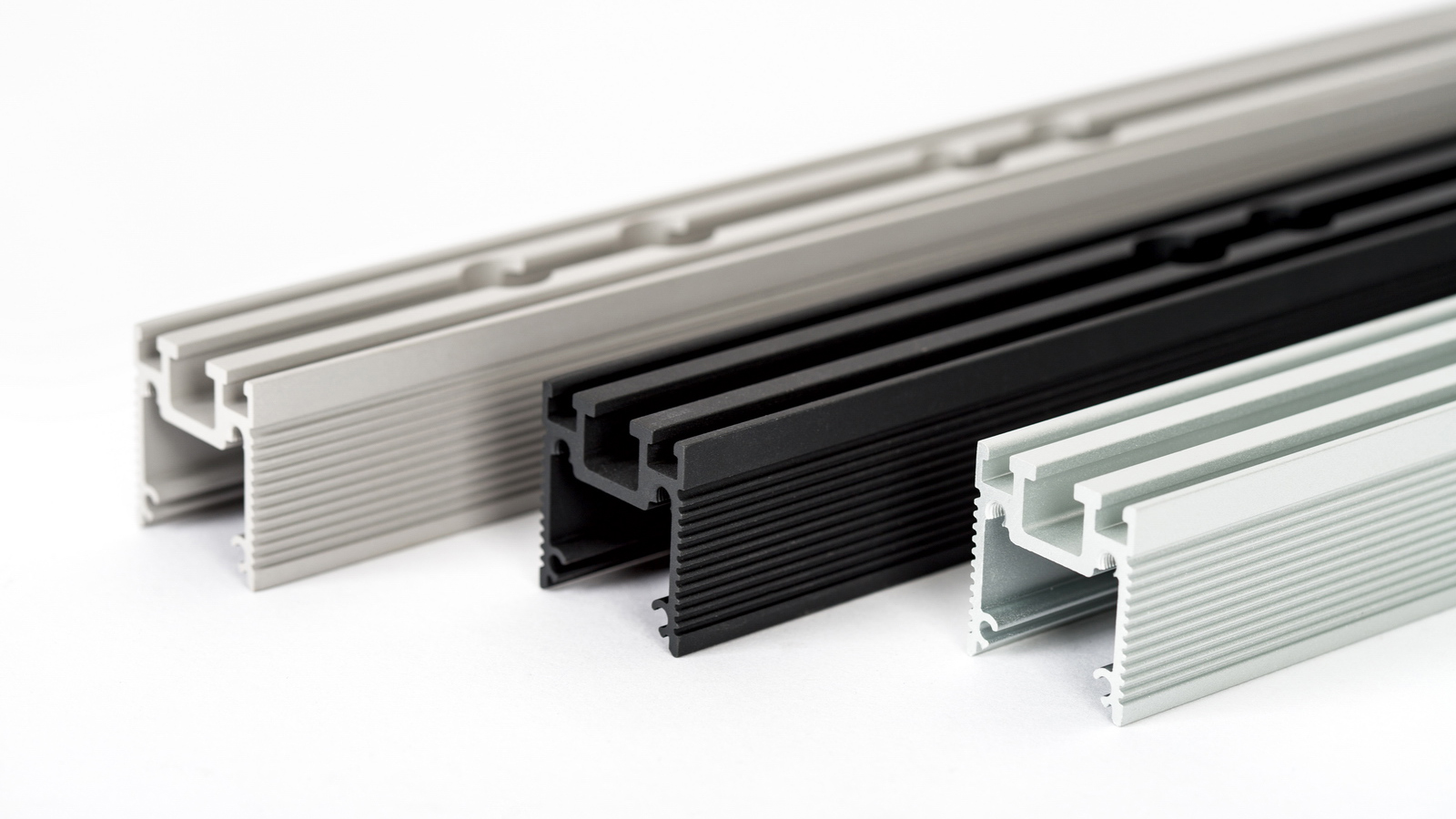

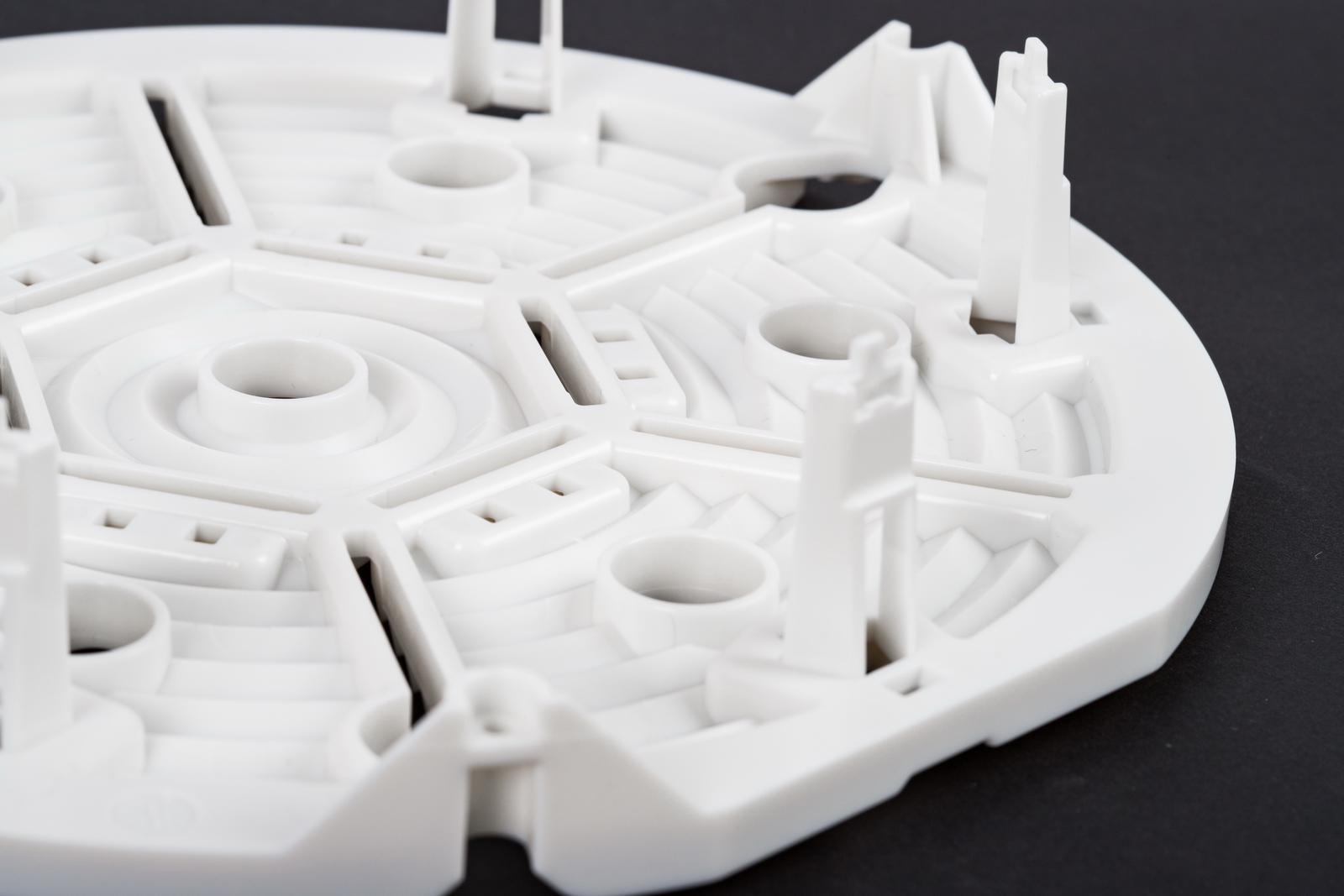

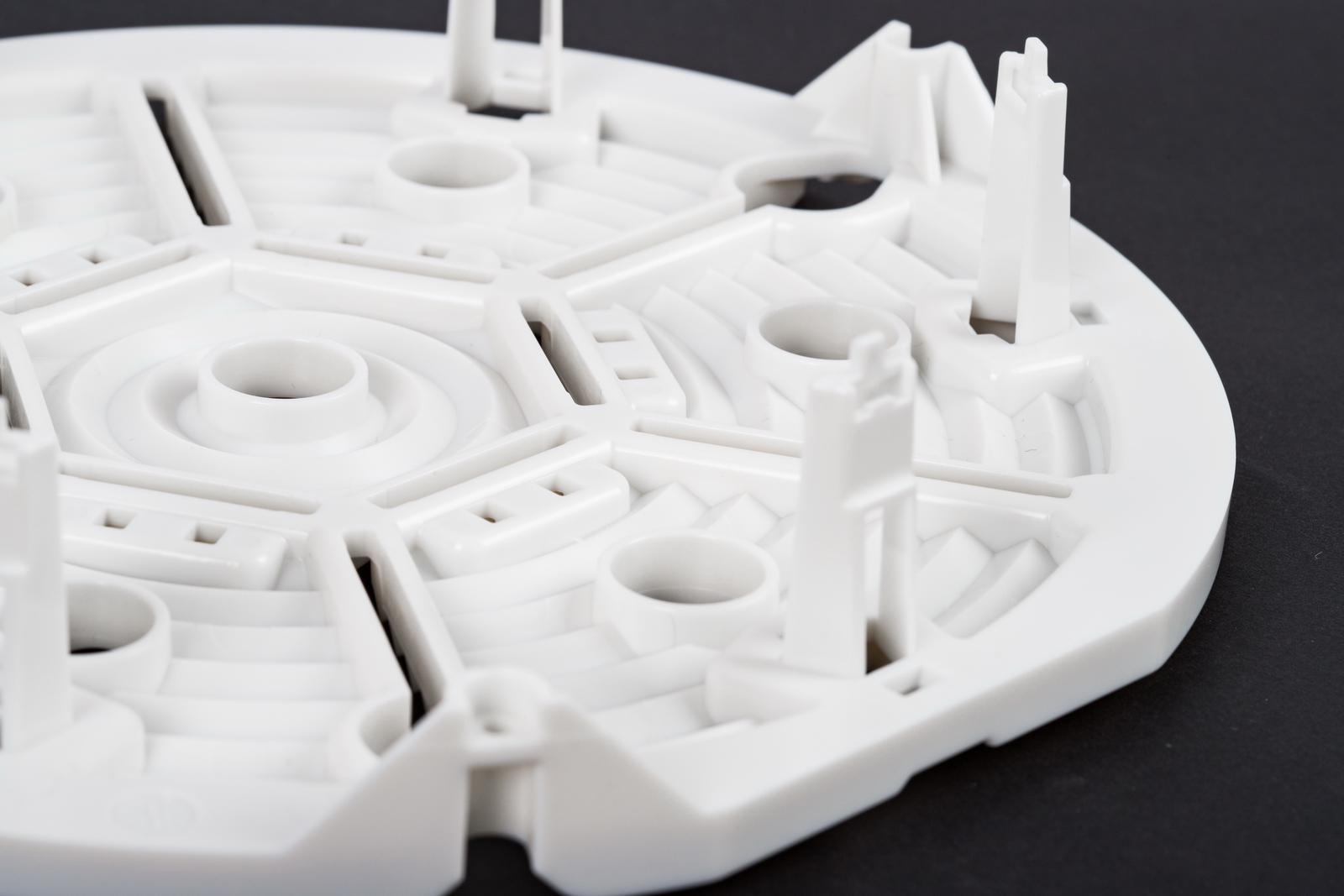

Mastars can offer a complete service for components and sub-assemblies manufactured in engineering polymers, all on one site. Secondary operations include inserting, painting, printing, hot staking, ultra sonic welding, chrome plating and Vacuum metallization. We have many years of experience in producing top-quality parts in all general and most engineering thermoplastic polymers including Ultem, PEEK and specially compounded polymers for conductivity and RF screening and other specialized requirements.

we provide rapid prototyping services and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.Our range of equipment includes 40 injection molding machines ranging from 50T to 650T clamping force and 20 machines with full robotics. This allows us the flexibility to manage both small volume and high-volume production batch sizes in the most efficient manner.

Acrylic (PMMA)

PMMA is also known by trade names such as Lucite, Perspex and Plexiglas. It serves as a sturdy substitute for glass for items such as aquariums, buttons, motorcycle helmet visors, aircraft windows, viewing ports of submersibles, and lenses of exterior lights of automobiles. It is extensively used to make signs, including lettering and logos.

ABS

Acrylonitrile butadiene styrene (ABS) is a terpolymer synthesized from styrene and acrylonitrile in the presence of polybutadiene. ABS is a light-weight material that exhibits high impact resistance and mechanical toughness. It poses few risks to human health under normal handling. It is used in many consumer products, such as toys, appliances, and telephones.

Nylon

Nylon (PA6/PA66) belongs to a class of polymers called polyamides. Nylon is used for mechanical parts including machine screws, gears, and power tool casings. In addition, it is used in the manufacture of heat-resistant composite materials.

Polycarbonate

Polycarbonate (PC) thermoplastics are known under trademarks such as Lexan, Makrolon, Makroclear, and arcoPlus. They are easily worked, molded, and thermoformed for many applications, such as electronic components, construction materials, data storage devices, automotive and aircraft parts, check sockets in prosthetics, and security glazing. Polycarbonates do not have a unique resin identification code. Items made from polycarbonate can contain the precursor monomer bisphenol A (BPA). Susceptible to UV light, exposure results in yellowing (degradation is especially visible in headlamps that lost or didn’t have a proper protective coating).

Polyether Sulfone

Polyether Sulfone (PES) or polysulfone is a class of specially engineered thermoplastics] with high thermal, oxidative, and hydrolytic stability, and good resistance to aqueous mineral acids, alkalis, salt solutions, oils, and greases.

Polyoxymethylene

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Celcon, Ramtal, Duracon, Kepital, and Hostaform.

Polyether Ether Ketone

Polyether ether ketone(PEEK) is a colorless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. It was originally introduced by Victrex PLC, then ICI (Imperial Chemical Industries) in the early 1980s. It has attractive properties like good abrasion resistance, low flammability and emission of smoke and toxic gases.

Polyetherimide

Polyetherimide (PEI), produced by a novel nitro displacement reaction involving bisphenol A, 4, 4’-methylenedianiline and 3-nitrophthalic anhydride, has high heat distortion temperature, tensile strength and modulus. They are generally used in high-performance electrical and electronic parts, microwave appliances, and under-the-hood automotive parts.

Polyethylene

Polyethylene (polyethene, polythene, PE) is a family of similar materials categorized according to their density and molecular structure. It is also known as poly and is obtained by the addition polymerization of ethylene. It may be of low density or high density depending upon the process used in its manufacturing. It is resistant to moisture and most of chemicals. It is flexible at room temperature (and low temperature) and can be heat sealed. Since it is an inexpensive plastic it is made in large amounts to cater to the demand. For example:

ultra-high-molecular-weight polyethylene (UHMWPE) is tough and resistant to chemicals. It is used to manufacture moving machine parts, bearings, gears, artificial joints and some bulletproof vests.

High-density polyethylene (HDPE), recyclable plastic no. 2, is commonly used as milk jugs, liquid laundry detergent bottles, outdoor furniture, margarine tubs, portable gasoline cans, drinking water distribution systems, water drainage pipes, and grocery bags.

Medium-density polyethylene (MDPE) is used for packaging film, sacks and gas pipes and fittings.

Low-density polyethylene (LDPE) is flexible and is used in the manufacture of squeeze bottles, milk jug caps, retail store bags and linear low-density polyethylene (LLDPE) as a stretch wrap in transporting and handling boxes of durable goods, and as the common household food covering.

Polyphenylene Oxide

Polyphenylene oxide (PPO), which is obtained from the free-radical, step-growth oxidative coupling polymerization of 2,6-xylenol, has many attractive properties such as high heat distortion and impact strength, chemical stability to mineral and organic acids, and low water absorption. PPO is difficult to process, and hence the commercial resin (Noryl) is made by blending PPO with high-impact polystyrene (HIPS), which serves to reduce the processing temperature.

Polyphenylene Sulfide

Polyphenylene sulfide (PPS) obtained by the condensation polymerization of p-dichlorobenzene and sodium sulfide, has outstanding chemical resistance, good electrical properties, excellent flame retardance, low coefficient of friction and high transparency to microwave radiation. PPS is principally used in coating applications. This is done by spraying an aqueous slurry of PPS particles and heating to temperatures above 370 °C. Particular grades of PPS can be used in injection and compression molding at temperatures (300 to 370 °C) at which PPS particles soften and undergo apparent crosslinking. Principal applications of injection and compression molded PPS include cookware, bearings, and pump parts for service in various corrosive environments.

Polypropylene

Polypropylene (PP) is useful for such diverse products as reusable plastic food containers, microwave- and dishwasher-safe plastic containers, diaper lining, sanitary pad lining and casing, ropes, carpets, plastic moldings, piping systems, car batteries, insulation for electrical cables and filters for gases and liquids. In medicine, it is used in hernia treatment and to make heat-resistant medical equipment. Polypropylene sheets are used for stationery folders and packaging and clear storage bins. Polypropylene is defined by the recyclable plastic number 5. Although relatively inert, it is vulnerable to ultraviolet radiation and can degrade considerably in direct sunlight. Polypropylene is not as impact-resistant as polyethylenes (HDPE, LDPE). It is also somewhat permeable to highly volatile gases and liquids.

Polystyrene

Polystyrene is manufactured in various forms that have different applications. Extruded polystyrene (PS) is used in the manufacture of disposable cutlery, CD and DVD cases, plastic models of cars and boats, and smoke detector housings. Expanded polystyrene foam (EPS) is used in making insulation and packaging materials, such as the “peanuts” and molded foam used to cushion fragile products. Polystyrene copolymers are used in the manufacture of toys and product casings.

Polyvinyl chloride

Polyvinyl chloride (PVC) is a tough, lightweight material that is durable, fairly rigid and versatile, and is resistant to acids and bases. Much of it is used by the construction industry, such as for vinyl siding, drainpipes, gutters and roofing sheets. It is also converted to flexible forms with the addition of plasticizers, thereby making it useful for items such as hoses, tubing, electrical insulation, coats, jackets and upholstery. Flexible PVC is also used in inflatable products, such as water beds and pool toys. PVC is also a common material in vinyl action figures, especially in countries such as Japan, where the material is used extensively in so-called Sofubi figures. As PVC bends easily and has a tendency to be bent during transit, a method to mitigate this deformation is to heat the plastic until it becomes mobile, then reform the material into the desired shape.

PVC is produced in many specific modifications to affect its chemical and physical properties. In plasticized polyvinyl chloride (pPVC), plasticizers are added to the raw material before molding to make it more flexible or pliable. Early on, the health and environmental aspects of this were poorly understood and replacements and product bans resulted after studies. The original form is often referred to as unplasticized polyvinyl chloride (uPVC), which is the more commonly used type for installations such as water, waste, and sewer conveyance plumbing.

Chemical modification often produces more drastic changes in properties. Chlorinated polyvinyl chloride (CPVC) is produced through exposing PVC to the continued free-radical chlorination reaction that originally formulates the PVC polymer. The chlorination reaction continues to add chlorine atoms to the polymer hydrocarbon backbone until most commercial applications reach a percent range between 56 and 74% total chlorine. This increase in elemental chlorine content contributes to CPVC’s increased expression of chlorine-based characteristics, such as chemical durability, resistance to acids, bases, and salts; susceptibility to ammonia-based compounds, aromatics, esters, ketones; chemical stability; heat energy transfer resistance. CPVC is commonly used in water, chemical, hot and cold, delivery systems for residential, commercial, and industrial applications.

Mastars has over 18 years of experience in injection molding, finishing and assembly work in every conceivable product category including industrial, automotive, medical, sports, automation& Robert, scientific, lighting, electronic product, aerospace, telecommunications. etc applications.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China