- [Art lighting solutions]Art lighting solutions01 Apr,2022

- Mastars has been immersed in the field of art lighting for more than ten years and has rich industry experience. Mastars has cooperated with Harman Martin, a global well-known enterprise, to develop and produce a series of art lighting since 2010.

-

- [FAQ]Rapid Prototyping Tooling Definition, methods,technologies31 Oct,2025

- Rapid Tooling (RT) is a broad term for a set of techniques that use additive manufacturing (3D printing) or other rapid processes to create molds, patterns, or dies—collectively known as "tooling"—much faster and at a lower cost than conventional methods.

-

- [FAQ]Metal Stamping: Professional Terminology31 Oct,2025

- This vocabulary provides a comprehensive foundation for communicating effectively with tool and die engineers, stamping press operators, and quality control personnel in the metal stamping industry.

-

- [FAQ]Metal Stamping: A Detailed Overview31 Oct,2025

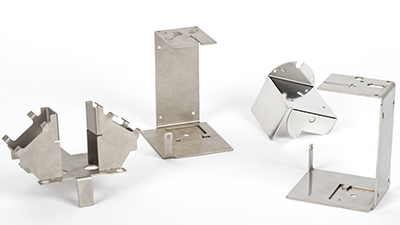

- Metal Stamping? is a high-volume, cold-forming manufacturing process that uses specialized presses and tooling (dies) to transform flat sheet metal (in coil or blank form) into a desired shape. It is a highly efficient and rapid process ideal for producing a vast range of parts, from simple brackets to complex, multi-component assemblies, with excellent repeatability and low per-part cost.

-

- [FAQ]Forging: Definition,Process and Advantage31 Oct,2025

- Forging is a foundational manufacturing process that involves shaping metal using localized compressive forces. These forces are delivered by a hammer, die, or press. Unlike casting, where metal is melted, forging plastically deforms the solid metal, typically at elevated temperatures, to achieve the desired shape.

-

- [FAQ]What Is Aluminum Extrusion? Definition, Types, & Benefits31 Oct,2025

- Aluminum Extrusion: A Detailed Overview 1. Executive Summary Aluminum Extrusion is a manufacturing process thattransforms aluminum alloy logs (billets) intoobjects with a specific cross-sectional profile. A preheated billet is forcedthrough...

-

- [Blog]Simulation Tools for Pressure Die Casting Molds30 Sep,2025

- Pressure die casting is a metal manufacturing process that involves injecting molten metal into steel moulds under high pressure. It’s widely used in industries like automotive, medical, and electronics to create complex, precise part...

-

- [FAQ]Mastars: Detail Guide About Aluminum Injection Molding16 Mar,2022

- Prototypes or real products are produced by the aluminum injection molding technique. The aluminum tooling technique is used for the process of aluminum injection molding. It is the process based on the injection molding technique. Mastars is also a metal prototype maker.

-

- [Blog]Why Use Copper Alloys in Pressure Die Casting?31 Aug,2025

- Copper alloys are a standout choice for pressure die casting, especially in Australia's demanding industries like automotive, mining, and electronics. Their combination of strength, thermal and electrical conductivity, and corrosion resista...

-

- [Blog]Top 5 Die Casting Alloys for Corrosion Resistance27 Aug,2025

- This article spotlights the top 5 corrosion-resistant die casting alloys for Australia’s climates (coastal salt, inland temperature swings). It details each on corrosion resistance, mechanics, climate fit, and OEM uses, plus compares them, covers Aussie OEM adaptation, testing, cost vs longevity, and answers FAQs.

-

- [News]Honda Introduces One-piece Molding Equipment for EV Parts12 Nov,2024

- Mastars die castings have been developing zinc and aluminum cast components for over 20 years. Refinements in the alloys and the process have expanded our applications to most market sectors. Size, shape, thickness, strength, and precision ...

-