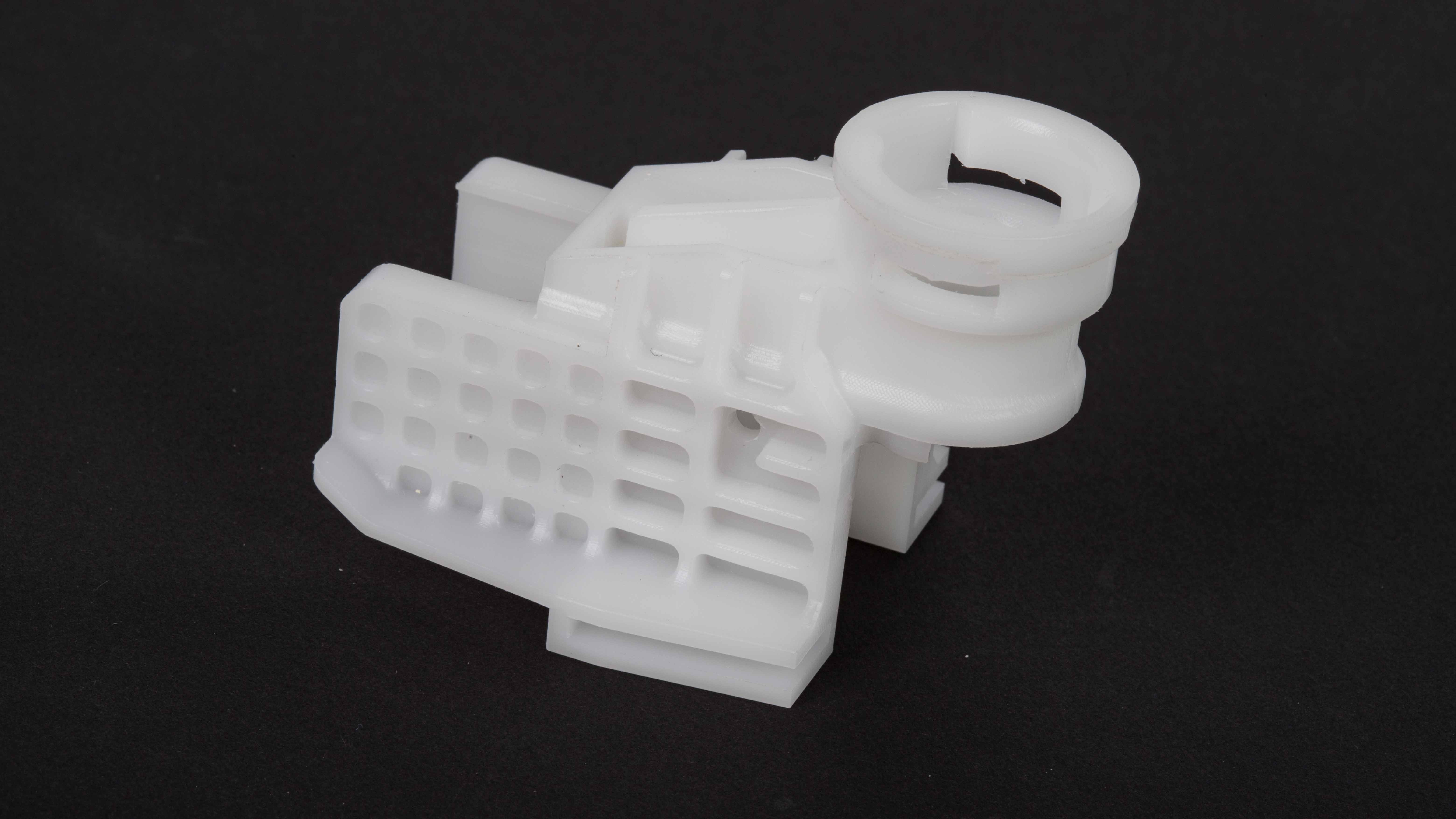

Precision plastic gear

Mastars is a large plastic mold manufacturer specializing in the production and processing of plastic molds and plastic products. It is committed to providing professional injection molding and plastic mold manufacturing,custom metal stamping, rapid cnc services.

1、 Concept and application of precision gear die

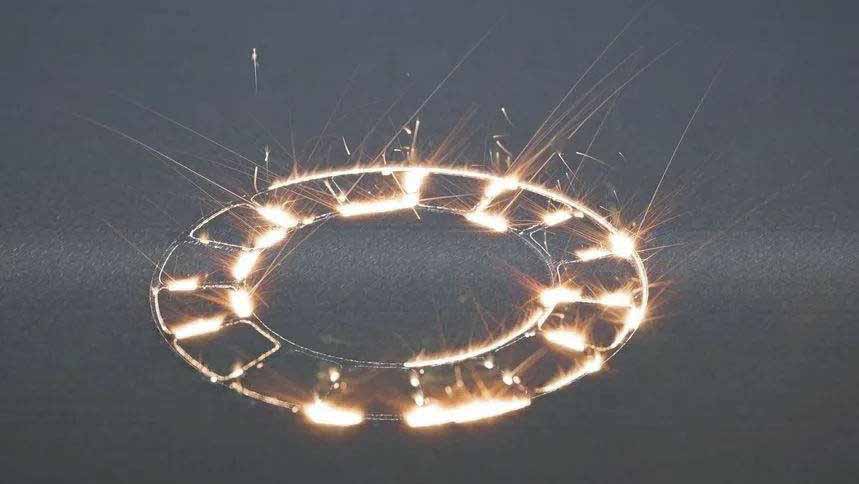

1) Precision gears have very high requirements for parameters, dimensions and performance. The parameters include the outer diameter of the addendum circle, the outer diameter of the tooth root circle, the module, the diameter of the dividing circle (also known as the common normal), the tooth thickness of the dividing circle, the pressure angle, the inclination angle of the helical teeth, and the runout tolerance of the ring gear; The performance includes the selection of materials and the accuracy requirements of other assembly dimensions.

2) In terms of application, representative products, such as the internal transmission parts of printers and copiers, commonly have VCD disc drive brackets. If the gears fail to meet the precision requirements, the movement of the brackets in and out will be unstable, accompanied by vibration or rocking, and the voice will be very loud. Through this, we can have a perceptual understanding of the concept of precision and its necessity.

3) Precision gears are graded in accuracy. The national standard says that the higher the grade, the more precision. The Japanese standard says that the smaller the grade, the more precision.

2、 Precision plastic gear type:

1) From the axial inclination angle of teeth, it is divided into spur gear, helical gear, combined spur gear, combined helical gear and combined spur and helical gear. The concept of combination is that spur or helical gears are distributed step by step in the axial direction, and one-time injection molding is performed.

2) There are mainly two kinds of transmission: meshing transmission gear and belt transmission gear.

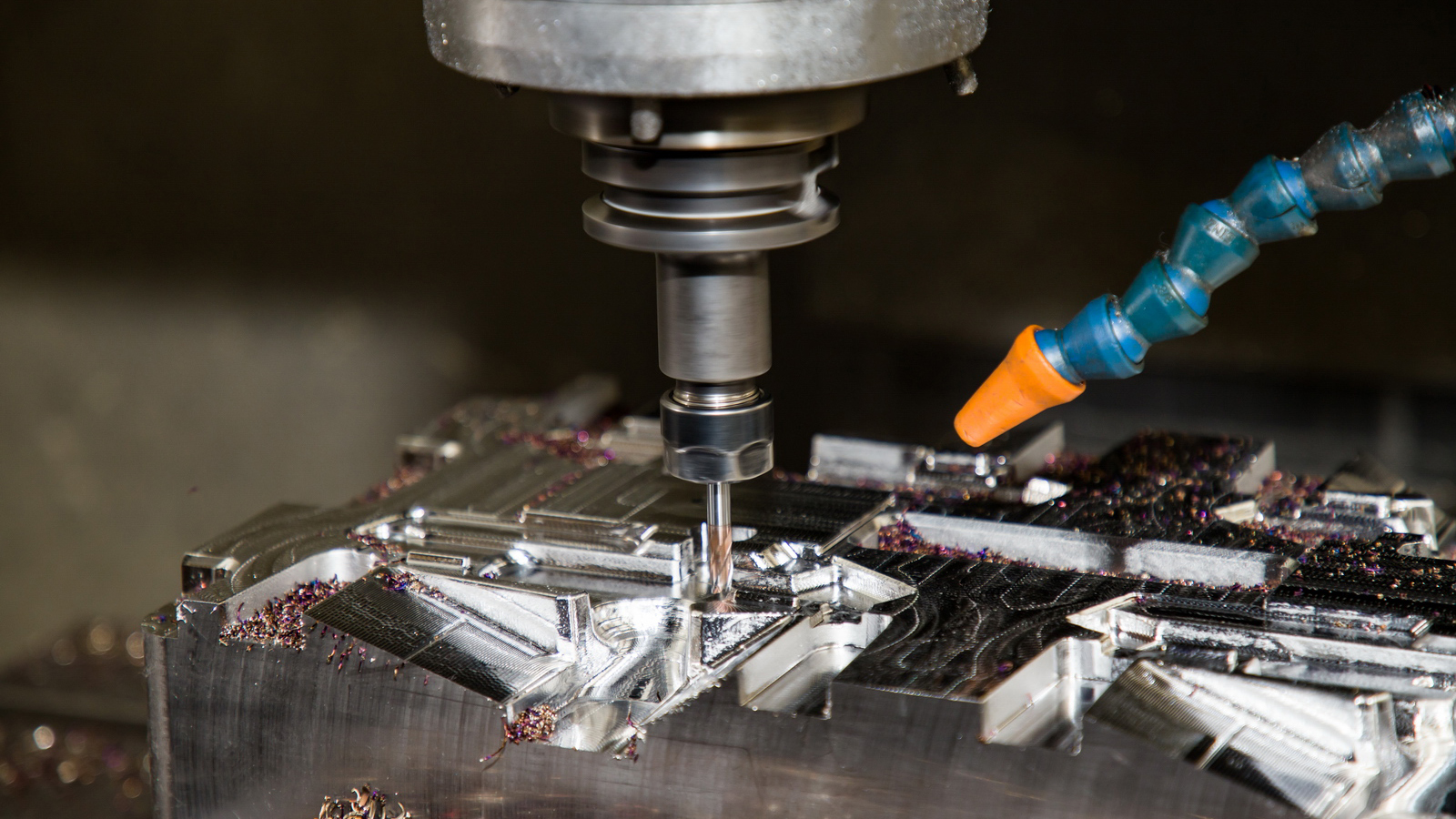

3、 Selection of mold embryo:

The precision of the mold embryo will directly affect the manufacturing and injection precision of the mold, and also affect the service life of the mold. Experience shows that it is difficult to meet the requirements of precision gear die with general die accuracy.

4、 Selection of plastic raw materials:

There are two main types: POM and PA (pa+gf%). Other raw materials, such as polysulfone, are not excluded. The most fundamental reason why POM and PA raw materials are preferred: the surfaces of POM and PA products have good self lubrication.

Other common reasons: good wear resistance, impact resistance and fatigue resistance; Secondly, POM products have high rigidity and excellent creep resistance; PA products have good toughness. If necessary, gf% can be added to enhance their rigidity. Generally, POM gears can be used for meshing transmission, and PA gears can be used for meshing transmission with POM gears

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China