-

-

Tips for reducing the cost of CNC prototypingMastars will use rapid prototyping mold and other techniques in the production of rapid prototyping. CNC is a commonly u...

-

-

2022-2028 Injection Molding Machine MarketThe global injection molding machine market reached USD 10.79 billion in sales in 2021 and is expected to reach USD 12.6...

-

-

BENTLEY

-

-

3D printing materials|3d printing manufacturing company|MastarsWe all know that 3D printing technology consists of three parts: molding process, 3D printing materials, high-precision ...

-

-

learn more about mastars sheet metal processingMastars employs proven prototype technologies(CNC machining, Sheet metal, Vacuum casting, 3D printing etc.), to take new...

-

-

How to select 10 Metal 3D printing technologies?|rapid prototyping servicesA few years ago, 3D printing with metal was only used in industry. Now all this has changed. Metal 3D printing can be re...

-

-

5 Key Points for Controlling CNC Machining AccuracyExplore five essential factors for achieving precision in CNC machining, from tool selection to workpiece setup, to enha...

-

-

Why Mastars is TrustworthyWhy do so many global automotive and medical device clients choose Mastars for long-term partnerships? It's not just bec...

-

-

Bentley limousine and hearseRemanufacturing Bentley Flying Spur vehicles into limousines and Hearse’s for the funeral market by Wilcox Limousines ,...

Contact us

- Building 6 , Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,Guangdong, China (518104)

- marketing@mastars.com

A Beginner's Guide to Injection Molding

Injection Molding: A Detailed Overview

1. Executive Summary

Injection Molding is a high-volume manufacturing

process for producing identical plastic parts with excellent dimensional

accuracy and repeatability. It involves injecting molten thermoplastic material

under high pressure into a precision-machined metal mold cavity, where it cools

and solidifies into the final shape. It is the most common method for

mass-producing plastic components, from tiny medical device parts to entire

automotive body panels.

2. Core Principle & Key Characteristics

The principle is

analogous to making Jell-O in a mold. A liquid material is poured into a shaped

cavity and allowed to set. In injection molding, the "liquid" is

molten plastic, and the "setting" is rapid cooling.

Key Characteristics:

-

High Production

Rate: Once the mold is built and the process

is optimized, cycle times (the time from injection to part ejection) can

be as short as 10-30 seconds, enabling immense volumes.

-

Low Per-Part Cost: Despite high initial tooling costs, the per-part cost becomes extremely

low at high volumes, making it economically unbeatable for mass

production.

-

High Repeatability

and Precision: The mold ensures that every part is

virtually identical, with tight tolerances and complex features replicated

perfectly.

-

Wide Material

Selection: A vast range of thermoplastic polymers

with specific properties (strength, flexibility, heat resistance, color)

can be used.

-

Minimal

Post-Processing: Parts often require little to no

finishing after ejection, as gates and ejector pin marks are designed to

be minimal.

3. The Injection Molding Process Cycle

The cycle is a

continuous, automated loop with four main stages:

1. Clamping

The two halves of

the mold are securely closed and held together by a clamping unit. The force

must be high enough to withstand the immense pressure of injection (often

hundreds of tons).

2. Injection

Plastic material

in granular form (pellets) is fed from a hopper into a heated barrel. A

reciprocating screw transports the pellets forward. The heat from the barrel

and the shear friction from the screw's rotation melt the plastic. The screw

then moves forward like a plunger, injecting the molten plastic under high

pressure into the mold cavity.

3. Cooling

The molten plastic

inside the mold begins to cool and solidify upon contact with the cold mold

walls. It takes the shape of the cavity. Cooling time is a significant portion

of the total cycle time. The design of cooling channels within the mold is

critical for efficiency.

4. Ejection

After sufficient

cooling, the clamping unit opens the mold. An ejection system,

typically consisting of pins, pushes the solidified part out of the mold. The

mold then closes, and the cycle repeats.

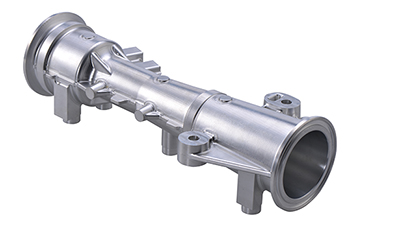

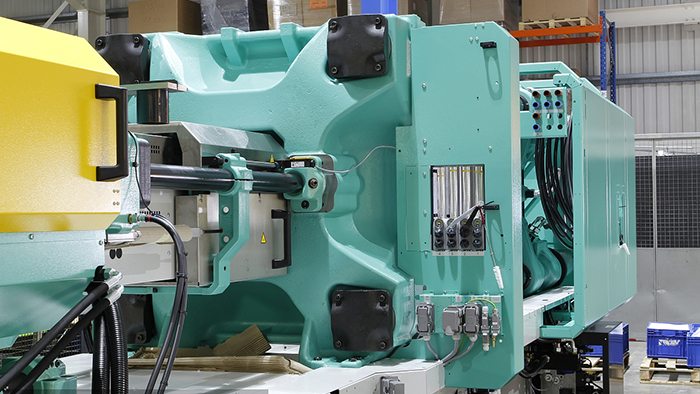

4. Key Components of the System

A. The Injection Molding

Machine (Press)

-

Clamping Unit: The

mechanism that opens, closes, and holds the mold with immense force

(measured in Clamp Tonnage).

-

Injection Unit: Comprises the hopper (feeds material), barrel (heats and melts material), and reciprocating screw (conveys, melts, and injects the material).

-

Control System: The

computer that precisely controls temperatures, pressures, speeds, and

timings.

B. The Mold (Tool or Tooling)

This is the most critical and expensive

element. It is typically made from hardened or pre-hardened steel or aluminum.

-

Core & Cavity: The

two halves that form the external and internal shapes of the part.

-

Sprue, Runners, and

Gates: The channel system that delivers the

molten plastic from the machine nozzle to the part cavity.

-

Sprue: The main channel from the nozzle.

-

Runners: The pathways that lead to the part cavities.

-

Gate: The small, controlled entrance to the part cavity.

-

Cooling Channels: Channels drilled throughout the mold through which a coolant (water or

oil) circulates to control the mold temperature.

-

Ejection System: Pins, sleeves, or blades that push the finished part out of the mold.

-

Vents: Small shallow channels or gaps that allow trapped air to escape as the

mold fills.

-

Draft: A

slight taper applied to vertical walls to allow the part to be ejected

easily.

5. Common Injection Molding Variations

-

Insert Molding: A metal

or ceramic component (an "insert") is placed into the mold, and

plastic is injected around it, creating a single, integrated part (e.g., a

threaded brass insert in a plastic housing).

-

Overmolding

(Two-Shot Molding): A process where a part is created with

two different materials. A substrate is first molded, then placed into a

second mold where a different material (often a soft-touch elastomer) is

overmolded onto it.

-

Gas-Assisted

Injection Molding: Inert gas (usually nitrogen) is

injected into the molten plastic. It creates hollow sections within thick

parts, reducing weight and sink marks while improving surface finish.

6. Design for Manufacturing (DFM) Considerations

Successful injection molding requires

adhering to specific design rules:

-

Uniform Wall

Thickness: This is the most critical rule.

Variations cause uneven cooling, leading to warping, sink marks, and

internal stresses.

-

Draft Angles: All

walls parallel to the mold opening direction must have a draft angle

(typically 1°-3°) to facilitate ejection.

-

Ribs: Used to add stiffness without increasing wall thickness. They should be

50-60% of the main wall's thickness.

-

Fillets and Rounds: Rounded corners (fillets) reduce stress concentration and improve material

flow.

-

Parting Line: The

line where the two mold halves meet. It must be considered for both

aesthetics and functionality.

7. Advantages and Limitations

|

Advantages |

Limitations |

|

Very low cost per part at high volumes. |

Extremely high initial cost for mold

tooling. |

|

Excellent repeatability and high

tolerances. |

Long lead times for mold design and

fabrication (weeks to months). |

|

Minimal waste; scrap can often be reground

and reused. |

Not economical for low volumes

(prototyping). |

|

Ability to produce complex geometries in a

single step. |

Part design is constrained by DFM rules

(e.g., draft angles, uniform walls). |

|

Wide selection of materials and colors. |

Significant startup time is required to

fine-tune the process for a new part. |

Conclusion

Injection Molding is the backbone of modern

mass production for plastic parts. While the initial investment in tooling is

substantial, its unparalleled efficiency, low per-part cost, and high-quality

output make it the undisputed choice for manufacturing millions of identical

plastic components across virtually every industry.

【Editor】:Mastarsall rights reserved:https://www.mastars.comPlease indicate the source