Forging: A Detailed Overview

1. Executive Summary

Forging is a foundational manufacturing process that

involves shaping metal using localized compressive forces. These forces are

delivered by a hammer, die, or press. Unlike casting, where metal is melted,

forging plastically deforms the solid metal, typically at elevated

temperatures, to achieve the desired shape. This process is renowned for

producing parts with superior strength, toughness, and structural integrity,

making it critical for high-stress applications in aerospace, automotive, and

heavy machinery.

2. Core Principle & Key Characteristics

The fundamental

principle of forging is the plastic deformation of metal grains. The application of force causes the internal grain structure

of the metal to recrystallize and flow, following the general shape of the

part.

Key Characteristics:

3. Primary Forging Methods

Forging processes

are categorized by the equipment used and the temperature at which the metal is

worked.

1. By Temperature:

|

Method |

Temperature Range |

Characteristics |

Common Applications |

|

Hot Forging |

Above the metal's recrystallization

temperature (e.g., >1000°C for steel). |

Metal is very ductile, allowing for

significant shape change. No strain hardening. Most common method. |

Engine crankshafts, connecting rods, gear

blanks. |

|

Cold Forging |

Room temperature. |

Excellent dimensional accuracy and surface

finish. Increases strength via strain hardening. Higher forces

required. |

Fasteners (bolts, screws), gears, shafts. |

|

Warm Forging |

Below recrystallization but above room

temperature (e.g., 500-900°C for steel). |

Balances the lower force of hot forging

with the precision of cold forging. Reduces strain hardening. |

Complex automotive components. |

2. By Equipment & Process:

|

Method |

Description |

Characteristics |

|

Open-Die Forging |

The workpiece is compressed between two

flat or simple-shaped dies while being manipulated by the operator. Also

called smith

forging. |

Produces large, simple shapes (blanks).

Excellent mechanical properties. Requires significant skill. |

|

Impression-Die Forging (Closed-Die

Forging) |

The workpiece is compressed between two

dies containing a precut impression of the desired part shape. Excess metal

forms flash, which is

trimmed off. |

The most common method for complex,

net-shape parts. High production rates. Excellent material utilization. |

|

Roll Forging |

Round or flat bars are passed through

opposing rolls with shaped grooves that reduce the cross-section and increase

the length. |

Used to produce parts with tapered

sections, like leaf springs and levers. |

|

Upset Forging |

The diameter of a bar or wire is increased

by compressing its length. This is done in a special upsetter or a

horizontal forging machine. |

Ideal for creating heads on fasteners like

bolts and nails. |

4. Forging Equipment

The machinery used defines the nature of the

forging process.

5. Key Terminology

|

Term |

Definition |

|

Billet / Bloom / Slab |

A semi-finished, rectangular or square form

that is the starting stock for many forging processes. |

|

Ingot |

A large, cast metal block that is the

initial product of a steel mill, often broken down into billets. |

|

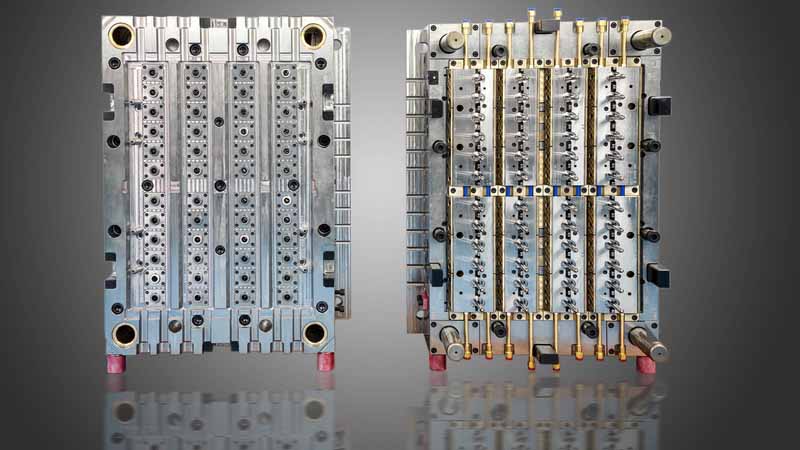

Die |

A hardened tool steel block containing the

impression of the part to be forged. |

|

Flash |

The thin layer of metal that squeezes out

into the gap between the dies during impression-die forging. It is later

trimmed off. |

|

Grain Flow (Fiber Flow) |

The directional pattern of the metal's

grain structure after forging, which follows the part's contour and is key to

its strength. |

|

Draft Angle |

A taper applied to the vertical walls of a

forging to facilitate its ejection from the die. |

|

Parting Line |

The plane where the two die halves meet. |

|

Trimming |

The secondary operation where the flash is

removed from the forged part. |

|

Heat Treatment |

A critical post-forging process (e.g.,

annealing, normalizing, quenching & tempering) used to achieve the final

mechanical properties. |

6. Advantages and Limitations

|

Advantages |

Limitations |

|

Superior Mechanical Properties: Unmatched

strength and toughness. |

High Tooling Cost: Dies,

especially for impression-die forging, are expensive. |

|

Reliability: The refined

grain structure provides consistent performance. |

Limited Complexity: Part geometry

is constrained; deep holes and undercuts are not possible. |

|

Material Efficiency: Near-net-shape

process reduces scrap. |

Size Limitations: Very large

forgings require immense, costly equipment. |

|

High Production Rate: Impression-die

forging is suitable for mass production. |

Secondary Operations: Often require

machining, drilling, and heat treatment. |

7. Common Applications

Conclusion

Forging remains an indispensable

manufacturing process where reliability and strength are

non-negotiable. By aligning the metal's grain structure with the

part's shape, forging creates components that can withstand extreme forces,

impacts, and fatigue, making it the process of choice for the most demanding

mechanical applications.