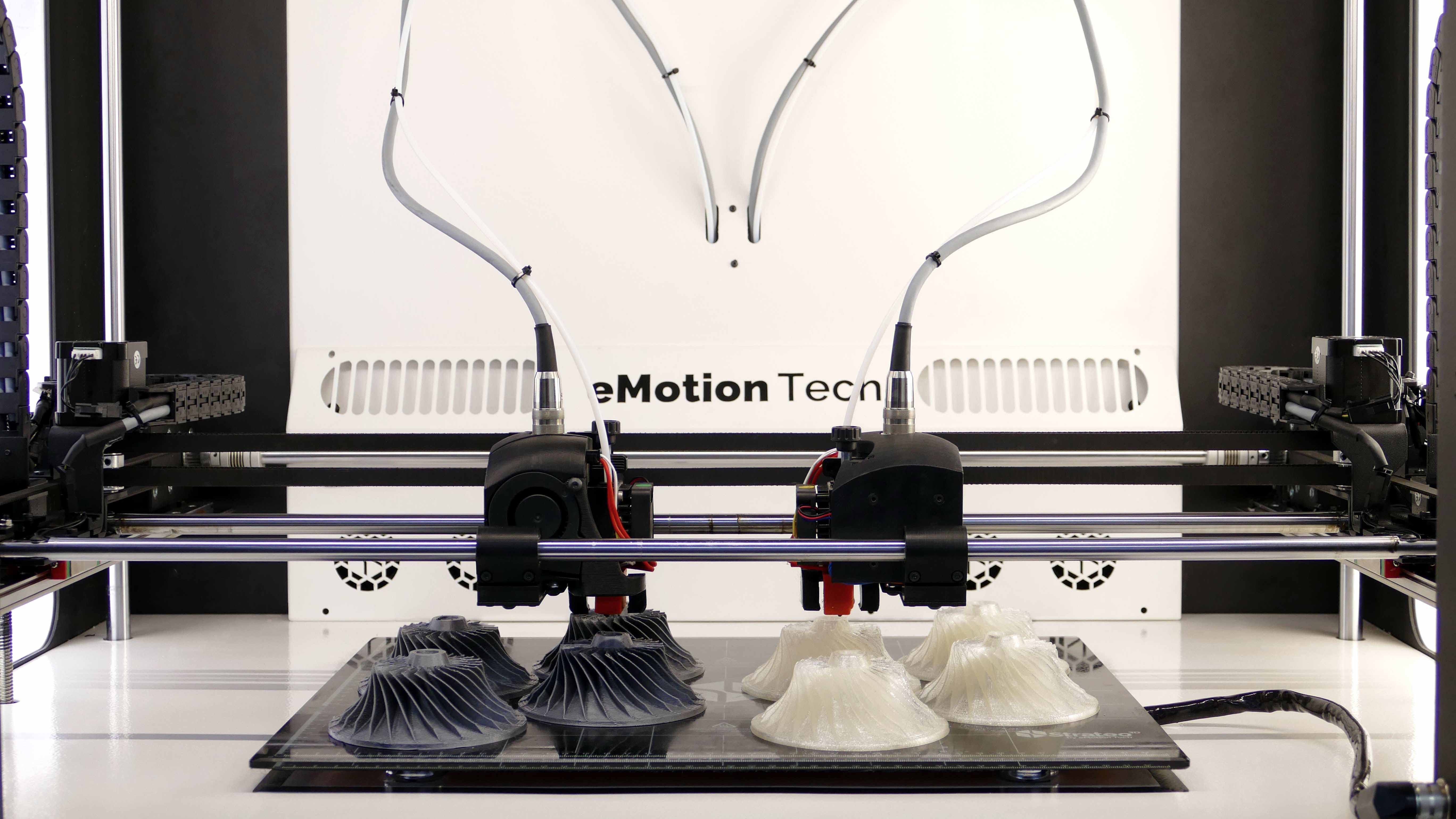

There are currently six factories worldwide, with a layout of three in the U.S., one in China, two in Europe, and two more to be built. The European plant in Berlin, Germany will start production of the new version of ModelY at the end of Q1 21 at the earliest, with the progress of the in-house battery plant lagging behind that of the full vehicle plant. Tesla's Austin, Texas plant has started construction and will start production as soon as June-July 21, mainly producing electric pickup trucks and truck Semi.

Tesla plans to build a total of 10-12 super factories worldwide.

Deutsche Bank believes that 2025 may be a "breakthrough year" for Tesla, which is expected to reach $94 billion in revenue and over 2 million vehicles delivered in 2025. However, short-term forecasts still depend on Tesla production and demand growth, especially on the progress of Tesla's superfactory construction in Texas and Germany.

Tesla's supply chain is divided into three categories: mass-produced traditional parts, mass-produced innovative parts, and North American innovative parts.

Among them, due to the rich experience in the field of traditional fuel vehicles, independent brands in the traditional parts of the chassis, suspension systems, glass, interior and exterior assemblies and other areas have a good supporting capacity and foundation. Mature supporting experience, adequate production capacity supply, competitive product prices have become the core capabilities of such companies to break through Tesla.

The high rate of localization is mainly concentrated in the

body chassis,

interior and exterior trim and other traditional components and automotive electronics in the hardware part, in the motor electric control, control chips and system software and other key components of the electric vehicle localization progress is temporarily slow.

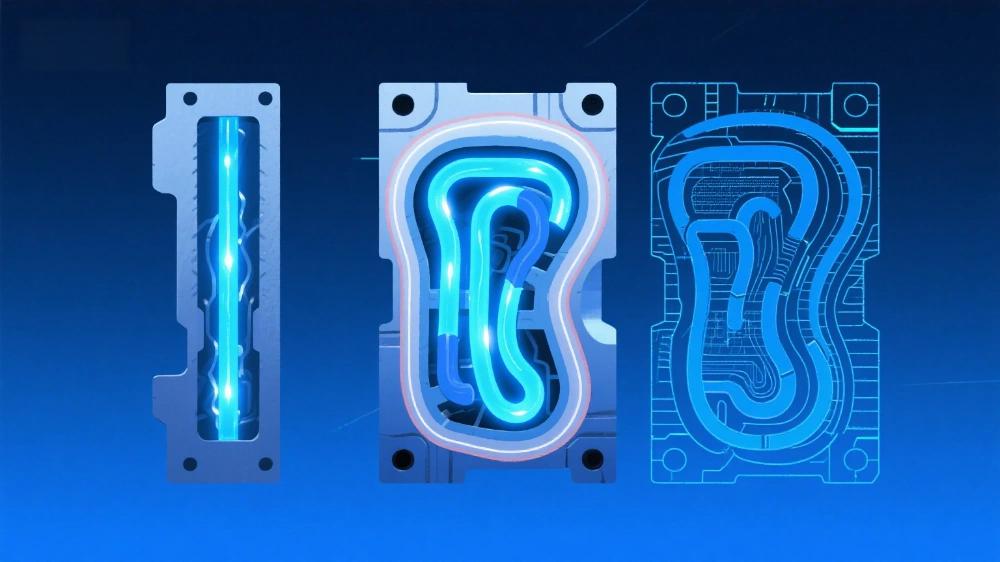

As most parts of the automotive industry chain have higher transportation costs, domestic procurement is more advantageous, therefore, Tesla's best-selling in the country will also drive the sales of the related industry chain to improve. Strong research and development, scale advantage of the battery, battery materials, thermal management system, electric drive system leading enterprises will enter the Tesla supply chain one after another, access to a larger growth space and product premium.

Tesla has "innovation gene", taking electric car as the starting point, three electric technology to ensure the performance of the vehicle, equipped with centralized electronic and electrical architecture, further realize the whole vehicle OTA, and through OTA gradually realize the fully automatic driving function; in this process, Tesla not only sells cars, but also realize business model transformation, providing FSD In this process, Tesla not only sells cars, but also transforms its business model to provide FSD and other services, and the scale effect is obvious.

Compared with traditional cars, Tesla lags behind in manufacturing and scale, and this is the next step in Tesla's growth to be solved, including accelerating production capacity and new model launch to open up a larger market.

Morgan Stanley analyst Adam Jonas wrote in the report, "Tesla remains the best positioned company in our research universe for

electric and self-driving cars due to its people, technology, business model and funding sources."

"In addition, it is worth noting that Tesla does not need to dwell on too much environmental responsibility at a time when its traditional competitors are under pressure to do so. All things considered, we believe Tesla's business model can unlock recurring mobile service revenues faster and more profitably than its competitors."