Injection moulding is a critical process in Australian industries like automotive and medical devices. It turns raw plastic into precise components but comes with challenges. Defects like warping, sink marks, flash, flow lines, and short shots can disrupt production, increase costs, and compromise safety. Fixing these issues requires optimising machine settings, improving material handling, and using quality control tools like sensors and thermal imaging.

By focusing on prevention and fine-tuning processes, Australian manufacturers can maintain high-quality standards and avoid costly disruptions.

Defects in injection moulding can compromise the quality of products and drive up production costs for Australian manufacturers. To tackle these issues, it's essential to understand the common defects and what causes them. Here's a closer look at some key problems and their origins.

Warping happens when a plastic part twists or bends out of shape instead of staying true to its intended design. This is usually caused by uneven cooling rates across the part. For instance, thicker areas cool slower than thinner ones, and variations in mould temperature can create internal stresses that lead to warping. Other factors include uneven wall thickness and ejecting the part too early.

Sink marks are small dents or depressions that often show up in thicker sections, ribs, or bosses of a part. These occur when the outer layer of plastic hardens before the inner material has fully cooled and contracted.

Flash refers to thin, excess plastic that leaks out along the mould's parting lines or around ejector pins. It's not just a cosmetic issue - it can indicate problems like misaligned moulds, excessive injection pressure, or insufficient clamping force. Worn mould surfaces can also allow plastic to escape into areas that should remain sealed.

Flow lines appear as streaks or wavy patterns on the surface of a part, marking the path of molten plastic as it fills the mould. These lines are most noticeable when the plastic cools too quickly at the flow front, preventing proper bonding with the material that follows. Common causes include lower melt temperatures, slower injection speeds, or gates positioned too far from the mould's extremities, allowing the plastic to lose heat along the way.

Burn marks show up as dark streaks or spots, often caused by trapped air or excessive friction and compression during moulding. High injection speeds, abrupt changes in the flow path, or overly high melt temperatures can lead to thermal degradation, resulting in these unsightly marks.

Air traps form when air gets caught in the mould cavity and can't escape through venting channels. This trapped air heats up under compression, potentially burning the plastic or preventing the cavity from filling completely. Poorly designed or positioned vents are often to blame.

Brittleness in moulded parts is usually linked to material degradation or unsuitable material choices. Overheating during processing can break down the polymer chains, making the plastic brittle and prone to cracking. For moisture-sensitive plastics like nylon or polycarbonate, inadequate drying can weaken the material. Contaminants from previous runs or degraded material in the barrel can also cause brittleness.

Weld lines form where two molten plastic flow fronts meet during cavity filling. These lines not only appear as visible seams but can also create weak spots, especially around features like holes or ribs. Low melt temperatures, insufficient injection pressure, or poor gate placement can prevent proper fusion at these junctions, reducing the part's strength.

Short shots occur when the mould cavity isn't completely filled, leaving parts with missing features or incomplete sections. This defect is often caused by insufficient injection pressure, too small a shot size, or overly viscous material. Cooler mould temperatures or narrow gates can make it harder for the plastic to flow into thin or detailed areas, resulting in incomplete filling.

Once you've identified the defects in your injection moulding process, the next step is to tackle them through precise adjustments to your machine settings. It's important to approach this systematically, as tweaking one parameter often affects others.

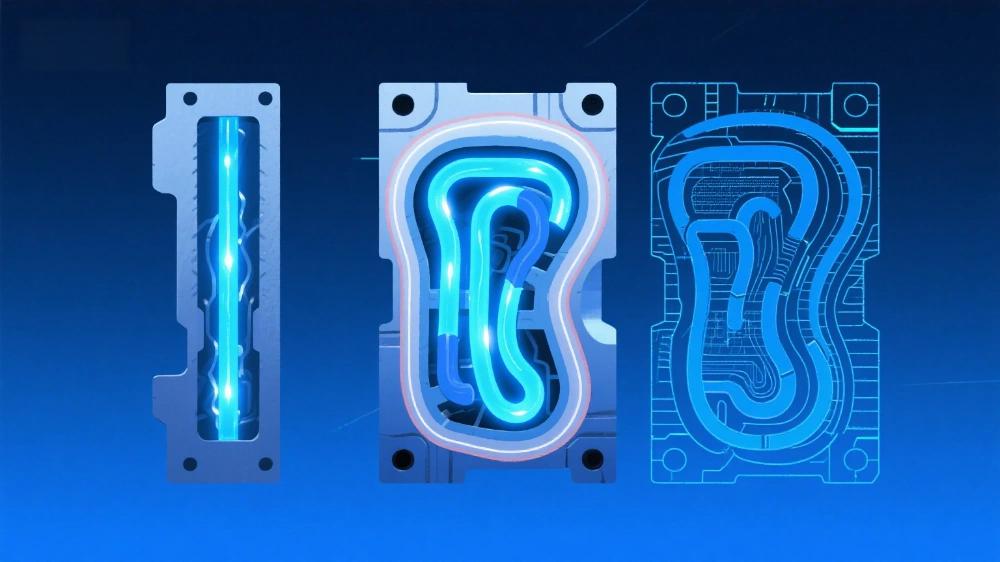

Fine-tuning machine parameters is your first line of action when addressing defects. The key settings to focus on include melt temperature, mould temperature, injection pressure and speed, packing/holding pressure, and cooling time.

Temperature control plays a major role in reducing defects. For instance, adjusting the mould temperature can help achieve more uniform cooling, which reduces internal stresses and prevents warping. Similarly, tweaking the melt temperature can improve material flow and minimise surface imperfections. Keep in mind that temperature changes can also affect cycle times and material behaviour, so proceed carefully.

Injection pressure and speed, along with clamping force, are equally important. Gradually increasing the injection pressure ensures the cavity fills completely, while proper clamping force helps prevent issues like flash.

Packing and holding pressure adjustments can address sink marks. By incrementally increasing these pressures, thicker sections of the moulded part can solidify more evenly. However, it's essential to make these changes step-by-step to avoid over-packing, which can lead to other problems.

Lastly, cooling time is critical for maintaining dimensional stability. Optimising the cooling duration can help reduce defects without unnecessarily lengthening the production cycle. These adjustments form the foundation for resolving defects before exploring other quality control strategies.

Once machine settings and mould designs are fine-tuned, maintaining defect-free production relies heavily on effective quality control tools. Successful injection moulding quality control blends traditional inspection methods with modern sensor technology to catch issues early and ensure production stays consistent. These tools not only support defect prevention but also help manufacturers uphold high standards of quality.

Modern quality control goes beyond basic inspections by integrating advanced monitoring systems that detect deviations from ideal conditions and enable immediate corrective actions.

At Mastars, the adoption of Industry 4.0 technologies has replaced subjective inspections with real-time, data-driven analysis. This shift not only improves defect detection but also ensures reliability and consistency. Additionally, data management software archives critical measurement data, creating a detailed quality record for every production run.

Preventing defects isn't just about maintaining high standards - it's also a smart financial and operational move. In injection moulding, defects can lead to much more than just wasted parts. Australian manufacturers who prioritise defect prevention often enjoy higher profit margins, smoother operations, and happier customers. By understanding the cost implications, businesses can make better decisions about investing in quality improvements.

Catching defects early can significantly cut costs. It reduces material waste, the need for rework, and the associated expenses of labour, machine time, and raw materials. This is especially important in high-volume production, where even a small defect rate can quickly add up to major expenses.

Early detection also keeps production schedules on track, helping manufacturers avoid delays and potential penalties. A smooth production process means fewer disruptions, less mould wear, and extended tool life - all of which help minimise downtime.

The financial benefits don't stop there. A stable, defect-free production environment not only reduces costs but also lays the foundation for more reliable products and better compliance with industry standards.

Preventing defects isn't just about saving money - it's about building trust and meeting essential standards. By implementing strong defect prevention systems, manufacturers can align with Australian Standards, such as AS/NZS ISO 9001. These standards emphasise the importance of documented processes and continuous quality improvement, making compliance audits much easier to navigate and certifications simpler to maintain.

Consistent quality enhances customer satisfaction and builds long-term trust. This is particularly crucial in industries like medical devices and automotive components, where reliability can make or break client relationships and market success.

Reducing defects also lowers warranty and liability risks. Defective products can lead to expensive recalls, warranty claims, and damage to a brand's reputation - not to mention the logistical headaches that come with them.

Low defect rates bring other advantages too. They allow manufacturers to better predict production capacity, plan resources effectively, and stick to delivery schedules. These factors contribute to smoother operations and stronger customer service.

Finally, having a proven track record of quality can be a game-changer when bidding for contracts. Australian companies that can showcase their defect prevention and quality control capabilities often stand out in competitive tendering processes, giving them an edge with major industry players.

To avoid warping and sink marks in injection moulding, it's crucial to maintain consistent wall thickness and carefully plan gate placement. These steps help ensure smooth material flow and even cooling, which can significantly cut down on defects.

When dealing with sink marks, placing gates near thicker sections and keeping draft angles uniform can make a big difference. To tackle warping, focus on achieving gradual, uniform cooling and ensure proper venting to prevent uneven shrinkage as the material sets.

By fine-tuning these aspects, you can boost the overall quality of your moulded products while cutting down on defects, ultimately saving both time and money.

The material you select is a cornerstone in reducing defects during injection moulding. Each material brings its own set of characteristics - like melting points, shrinkage rates, and flow behaviours - that directly influence issues such as warping, sink marks, and surface flaws.

When deciding on a material, keep these key aspects in mind:

By thoroughly assessing these aspects, you'll be better equipped to minimise defects and deliver reliable, high-quality products in your manufacturing process.

Maintaining consistent production quality in injection moulding requires advanced quality control tools. These tools enable real-time monitoring of crucial variables like pressure, temperature, and material flow, ensuring any deviations are quickly spotted and corrected.

Techniques like statistical process control (SPC) play a key role in this process. They help detect potential problems early, allowing manufacturers to take swift action. The result? Lower defect rates, reduced waste, and products that consistently meet high standards. By integrating these tools into their workflow, manufacturers can boost both efficiency and reliability in production.

Achieving success in injection moulding hinges on mastering the basics and applying them consistently. One guiding principle to always keep in mind: it's far more cost-effective to prevent defects than to fix them later. This mindset should shape every step of your manufacturing process.

Common defects like warping, sink marks, flash, flow lines, and short shots each have clear causes and proven fixes. Whether it's tweaking machine settings like temperature and pressure, selecting the right materials, or refining mould design, every defect has a specific solution. Addressing these issues proactively can save both time and money.

Machine settings are critical for high-quality outcomes. Factors such as temperature control, injection speed, and holding pressure need to be fine-tuned for each material and part design. Even small, well-documented adjustments can lead to noticeable improvements in quality.

Material selection and handling are equally important. Properly drying, storing, and managing materials can prevent a host of issues before they even arise. Knowing how different plastics behave during moulding allows you to anticipate challenges and make necessary adjustments. When combined with precise machine settings, good material management forms the backbone of a defect-free process.

Continuous quality control is essential to maintain these standards. Monitoring the process - not just the final product - ensures consistent results. Techniques like statistical process control, regular measurements, and thorough documentation establish a reliable production framework. This is especially crucial in high-volume manufacturing, where even minor defect rates can quickly snowball into significant costs.

Preventing defects not only cuts down on waste and delays but also boosts profitability. Less rework, fewer disruptions, and happier customers all contribute to a stronger bottom line. Many Australian manufacturers who prioritise robust quality systems find themselves better positioned to command premium pricing and secure long-term contracts.

For Australian businesses aiming to achieve consistent, high-quality injection moulding results, Mastars offers a comprehensive solution. Their expertise spans rapid prototyping to full-scale production, backed by strict quality control processes and Industry 4.0 technologies. With applications across automotive, medical devices, and consumer electronics, Mastars helps Australian manufacturers deliver reliable, high-quality outcomes.