Surface finishes for CNC car parts are more than just about looks - they're about performance, durability, and protection. Choosing the right finish can ensure your automotive components withstand harsh conditions, including Australia's UV exposure, coastal salt, and temperature extremes. Here's a quick breakdown:

Key Takeaway: The right surface finish depends on the material, application, and environment. For example, anodised aluminium resists corrosion in coastal areas, while hard coatings like PVD excel in high-friction parts like transmissions. By balancing durability, cost, and appearance, you can optimise your automotive parts for long-term performance.

Quick Tip: Always account for Australia’s unique conditions - UV exposure, salt, and temperature changes - when selecting finishes.

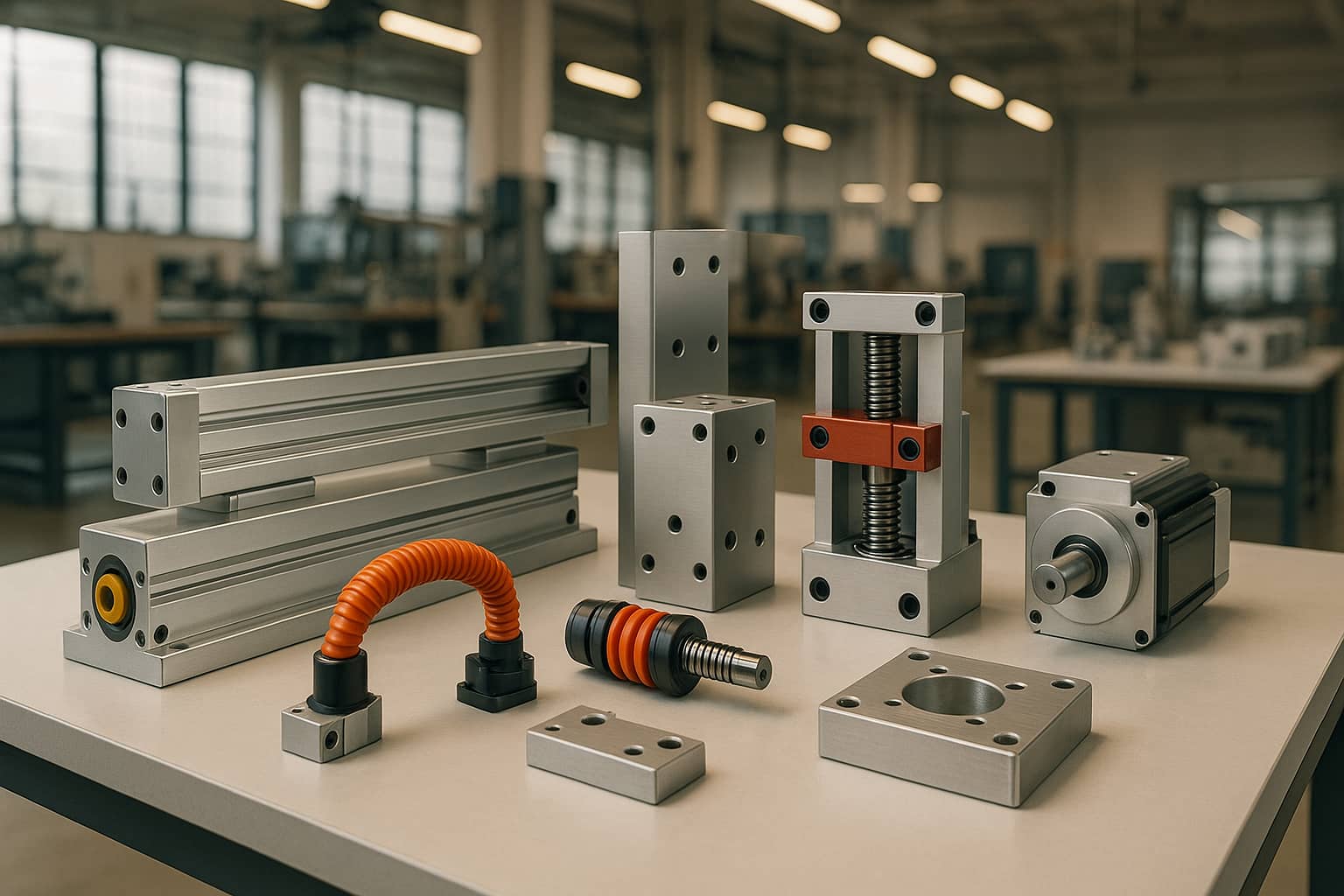

In the automotive industry, surface finishing is a crucial step in transforming raw CNC-machined components into high-quality, production-ready parts. These finishing techniques not only enhance durability but also improve the aesthetics of the components. Mastars specialises in a range of finishing methods, ensuring that automotive parts meet both functional and visual requirements.

Anodising is a process that enhances aluminium surfaces by creating a protective oxide layer through electrochemical oxidation. This layer is much harder than the base material, offering excellent protection against wear and corrosion. The process involves immersing aluminium parts in an electrolytic solution and applying an electrical current, which forms a porous oxide coating on the surface.

Type II anodising is particularly effective for automotive components, providing corrosion resistance while maintaining precise dimensions. The porous nature of the anodised layer also allows for the application of dyes, ensuring consistent colour matching across parts. For high-stress applications, such as engine brackets and suspension components, Type III (hard anodising) is used. This creates a thicker, denser oxide layer that withstands harsh conditions.

Mastars further enhances anodised parts by sealing the oxide layer with a hot water treatment. This not only locks in colours but also boosts corrosion resistance, making it ideal for exterior trims and decorative elements. For those looking for a different approach, powder coating offers another durable and visually appealing option.

Powder coating involves applying dry polymer powder to metal surfaces using an electrostatic process, followed by curing in an oven at temperatures between 160-210°C. Unlike traditional liquid paints, powder coatings are solvent-free, making them environmentally friendly and highly durable.

The electrostatic application ensures even coverage, eliminating common issues like runs or thin spots. Polyester powder coatings are particularly suited for exterior automotive parts, as they resist UV rays and maintain their colour even under Australia's intense sunlight and temperature fluctuations. Epoxy-polyester hybrids combine epoxy's chemical resistance with polyester's weatherability, making them versatile for both interior and exterior applications.

Mastars employs infrared curing technology alongside traditional convection ovens to speed up the curing process without compromising the quality of the coating. This ensures a durable, cross-linked polymer structure while allowing for quicker turnaround times.

Mechanical treatments refine the surface texture of components by removing or deforming material in a controlled manner. These methods improve both functionality and appearance without adding additional layers.

For applications requiring extreme durability, advanced coating techniques such as PVD and CVD provide cutting-edge solutions.

Advanced coating methods like Physical Vapour Deposition (PVD) and Chemical Vapour Deposition (CVD) take surface finishing to the next level by applying thin films at an atomic scale. These techniques are ideal for high-performance automotive parts that demand superior wear resistance and durability.

Mastars also offers plasma-enhanced CVD technology, which lowers processing temperatures without sacrificing coating quality. This makes it possible to treat temperature-sensitive materials and intricate geometries that traditional CVD methods cannot handle.

Picking the best surface finish for CNC machined automotive parts involves balancing functionality, aesthetics, costs, and production timelines. Engineers need to consider performance requirements alongside design goals while factoring in Australia's distinct environmental conditions, which can significantly impact the durability and effectiveness of surface treatments.

Building on the techniques discussed earlier, here are key factors to guide the selection process.

The choice of surface finish often depends on the material. For instance, anodising works well for aluminium, black oxide is ideal for steel and iron, while passivation enhances the corrosion resistance of stainless steel. Each process is tailored to ensure durability and performance.

For stainless steel, passivation is a critical step. This nitric acid treatment removes free iron from the surface, creating a stable chromium oxide layer that boosts corrosion resistance. This is particularly important for components like fuel systems or brake assemblies.

Functionality also plays a big role. Components exposed to high friction, such as those in transmissions, benefit from low-friction coatings like diamond-like carbon (DLC). On the other hand, parts requiring better grip, such as pedal surfaces, may use textured finishes achieved through bead blasting or chemical etching. For load-bearing parts, finishes like hard anodising or PVD coatings ensure strength without compromising durability.

Mastars employs these material-specific techniques to meet both technical and visual demands.

The appearance of automotive parts matters, especially for visible components. Mechanical finishing can control texture and achieve specific visual effects without sacrificing functionality. For example, a brushed finish gives a satin-like look that not only looks appealing but also hides minor scratches and wear.

Maintaining consistent colour across multiple components is another challenge. Anodised aluminium, when processed in the same batch, can achieve good colour matching, though slight variations may occur due to differences in alloy composition or machining settings. Mastars addresses this by carefully selecting materials and managing batch processes to ensure uniform results.

Gloss levels also impact the perceived quality. High-gloss finishes, achieved through polishing and clear coating, give a premium appearance but show fingerprints and scratches more easily. Satin or matte finishes, while less striking, tend to be more durable in harsh environments.

The design itself must align with the finishing process. Complex shapes with deep recesses or internal channels can pose challenges for certain coatings. For example, PVD coatings require direct exposure to the vapour source, making them less effective for intricate parts. Addressing these limitations during the design phase can save time and costs down the line.

While some finishes may seem cost-effective upfront, they can lead to higher expenses over time. For example, powder coating might cost more initially than liquid paint, but its durability can reduce warranty claims and replacement costs in the long run. Total costs should account for material and processing expenses, quality control, and potential field failures.

Production timelines vary depending on the finish. Simple processes like bead blasting are quick, while more complex techniques like PVD coatings can take several days due to preparation and processing requirements. Mastars uses detailed scheduling to help engineers plan production timelines, including allowances for rework if needed.

Environmental regulations in Australia also influence the choice of finishes. For example, powder coating produces fewer volatile organic compound (VOC) emissions compared to liquid paint, making it a better option for facilities in urban areas with strict air quality standards. Additionally, powder coating overspray can often be reclaimed, reducing material waste and disposal costs.

Australia's climate presents unique challenges. Daily temperature fluctuations can cause coatings to expand or contract, potentially leading to failure. Choosing finishes with thermal expansion properties that match their substrates - like anodised aluminium - can improve durability. Intense UV exposure can also degrade organic coatings over time, making UV-stable powder coatings a popular choice for exterior components.

Mastars' process planning balances cost, environmental compliance, and production speed to ensure reliable results tailored to Australian conditions.

| Finish Type | Best Materials | Durability | Cost Range (AUD) | Lead Time | Key Benefits | Limitations |

|---|---|---|---|---|---|---|

| Type II Anodising | Aluminium alloys | High | A$15–25/m² | 3–5 days | Corrosion resistance, colour options | Limited to aluminium; minor dimensional changes |

| Type III Hard Anodising | Aluminium alloys | Very High | A$25–40/m² | 5–7 days | Wear resistance, surface hardness | Higher cost; potential brittleness |

| Powder Coating | Steel, aluminium | High | A$20–35/m² | 2–4 days | Durable, eco-friendly | Thickness limits; colour matching issues |

| PVD Coating | Most metals | Very High | A$50–100/m² | 7–10 days | Exceptional hardness, thin layers | High cost; requires line-of-sight |

| Black Oxide | Steel, iron | Moderate | A$8–15/m² | 1–2 days | Cost-effective, minimal dimensional impact | Limited corrosion protection |

| Passivation | Stainless steel | High | A$10–20/m² | 1–3 days | Boosts corrosion resistance | No aesthetic improvement |

| Bead Blasting | Most metals | Moderate | A$5–12/m² | 1 day | Prepares surfaces, provides uniform texture | No corrosion protection |

This table highlights the trade-offs between cost, durability, and lead times. For example, black oxide offers good value for internal parts with moderate corrosion resistance needs, while PVD coatings are ideal for high-performance applications where failure is not an option. Quick processes like bead blasting are great for fast turnarounds but may need additional coatings for long-term protection. Mastars' expertise ensures that the right combination of treatments is chosen to meet both production and performance goals.

Mastars employs a meticulous five-step process to deliver precision and durability in automotive CNC parts. By combining advanced technology with rigorous quality checks, the company ensures its methods align with Australia's automotive standards and environmental conditions. From the initial consultation to the final delivery, every step is carefully managed to achieve optimal results. Here’s a closer look at their approach.

The process kicks off with an in-depth consultation where Mastars' engineers collaborate with clients to fully understand their needs. This involves analysing technical drawings and material specifications to determine the best finishing techniques.

Key factors considered during this phase include the operating environment, load requirements, and aesthetic goals. Australia's unique climate challenges, such as UV exposure, extreme temperature shifts, and salty coastal air, are also taken into account.

Material compatibility is a critical focus. Engineers assess whether the chosen base material can support the desired finish, identifying any potential issues early. For example, aluminium alloys are closely examined since different alloys react differently to anodising treatments.

Regulatory compliance is another priority. The team ensures all treatments adhere to Australian Design Rules (ADR) and relevant industry standards. Cost considerations and production timelines are also discussed to align expectations and project goals.

Before surface treatments can begin, parts go through a multi-step cleaning process to remove machining oils, cutting fluids, and other contaminants that might interfere with the finish.

The preparation typically starts with degreasing, using either alkaline cleaners or solvent-based systems, depending on the material and type of contamination. For aluminium parts, an etching process follows, creating a consistent surface texture and removing the natural oxide layer.

At this stage, surface inspection identifies any defects, such as scratches or tool marks, that could impact the final finish. Minor flaws can often be resolved with mechanical polishing or chemical treatments, while more severe issues may require reworking the part.

Quality checks during preparation include surface roughness measurements and cleanliness tests, such as water break or contact angle assessments. These steps ensure a uniform foundation for the next phase.

The surface treatment process varies depending on the chosen technique, but all methods follow tightly controlled parameters to ensure consistent results. Key factors like temperature, timing, and chemical concentrations are carefully monitored.

For anodising, parts are mounted on fixtures to ensure even current distribution and avoid marking. The electrolytic process is automated to maintain precise voltage and current density.

Powder coating involves applying an electrostatic charge in controlled spray booths, followed by curing in convection ovens. Coating thickness is measured with non-destructive techniques to guarantee uniform coverage.

In PVD coating, parts are placed in vacuum chambers with precise temperature control. Ion bombardment cleans the surface before the coating is applied.

Throughout the process, automated monitoring systems track critical variables. Any deviations trigger immediate corrective actions, ensuring the final finish meets strict specifications. Once the treatment is complete, thorough quality checks validate the results.

Every treated part undergoes rigorous inspection to ensure it meets all specifications. This includes both visual checks and detailed testing with calibrated equipment.

Coating thickness is measured using methods like magnetic induction or eddy current techniques, depending on the material. For anodised parts, measurements are taken at multiple points to confirm uniformity, with tolerances typically within ±2 micrometres for decorative finishes and ±5 micrometres for hard anodising.

Adhesion testing is performed using techniques such as cross-hatch or thermal shock tests, while corrosion resistance is evaluated through salt spray testing. Exposure times range from 24 hours for decorative finishes to over 1000 hours for critical components.

For parts requiring specific colours, colour matching is verified with spectrophotometry to ensure consistency across batches. All test results, batch parameters, and any corrective actions are documented to maintain traceability and support continuous improvement.

After inspection, parts are carefully packaged to protect their surfaces during transit and storage. Packaging adheres to Australian transport regulations and is tailored to customer needs.

Protective measures include individual wrapping for delicate finishes, foam padding for complex shapes, and moisture barriers for humidity-sensitive parts. For example, anodised aluminium is wrapped in acid-free tissue paper, while powder-coated parts may use protective films.

Packaging materials are chosen based on the transport method and destination climate. Parts heading to tropical areas get extra moisture protection, while those for mining applications receive additional impact shielding.

Each shipment includes detailed documentation, such as compliance certificates, test reports, and handling instructions. Mastars works with trusted transport providers experienced in handling precision components to minimise damage risks.

The entire process typically takes 5-14 days, depending on the complexity of the treatments, with expedited options available for urgent projects. Regular updates keep customers informed, ensuring seamless integration with their schedules.

Surface finishes play a crucial role in determining how long automotive components last, especially under the tough conditions often seen in Australia. The right surface treatment can mean the difference between a part that performs reliably for years and one that fails prematurely, requiring costly replacements.

Automotive components face unique challenges depending on their function, and selecting the right surface treatment is crucial for durability and performance.

Mastars' extensive experience highlights the importance of selecting the right materials and finishes. For example, different aluminium alloys may require specific adjustments during anodising to achieve a consistent look, while steel components often benefit from phosphate treatments to improve powder coating adhesion. These tailored approaches are critical for ensuring that finishes perform reliably in Australia's demanding conditions.

Australia’s environment, with its coastal salt exposure, extreme temperatures, and intense UV radiation, puts surface finishes to the test. Field reviews have shown that well-chosen treatments significantly enhance component performance under these conditions.

Mastars' internal testing consistently shows that selecting the right surface treatment enhances component longevity and performance. For example, treated parts used in coastal and mining environments have demonstrated better resistance to wear and maintained their appearance longer than untreated ones. Rigorous quality checks ensure that every finish meets the demands of real-world applications.

Tailoring finishes to the specific environmental challenges of each application is essential. Components in tropical regions may require additional moisture protection, while those in arid zones benefit from UV-stable finishes. This customised approach ensures optimal performance while keeping treatment costs in check.

Selecting the right surface finish is essential for ensuring performance, durability, and reliability, especially in the challenging Australian environment. With factors like coastal salt exposure, extreme heat, and intense UV radiation, choosing the right surface treatment becomes even more critical for automotive applications.

Every automotive component requires a customised approach, taking into account material compatibility, environmental challenges, and performance goals. Success lies in understanding these specific needs and pairing them with the most suitable treatment methods.

While some advanced treatments, such as PVD coatings, may involve higher initial costs, they often pay off in the long run by enhancing performance and reducing maintenance expenses. Making informed decisions about surface treatments can help achieve durable and cost-effective results.

Mastars leverages its extensive expertise in surface treatments to deliver solutions tailored to specific automotive needs. By addressing the increasing demands for performance and adhering to stricter environmental standards, Mastars provides strategies that meet industry expectations. Through careful evaluation of materials, functionality, and environmental factors, engineers and designers can confidently choose treatments that ensure reliable, long-lasting outcomes for CNC automotive components.

When choosing a surface finish for CNC car parts in Australia, you need to factor in the country's distinct environmental conditions. With intense UV exposure, temperature swings, and high humidity, the wrong finish could lead to issues like corrosion, fading, or premature wear.

To ensure durability and long-lasting performance, finishes like anodising, powder coating, or specialised automotive coatings are excellent choices. These finishes not only offer strong protection against UV rays and corrosion but also maintain a tough, attractive surface. Make sure the finish suits the part’s purpose and the specific challenges it will encounter on Australian roads.

PVD (Physical Vapour Deposition) and CVD (Chemical Vapour Deposition) are two popular coating methods in automotive manufacturing, each with its own strengths.

PVD coatings stand out for their durability and excellent adhesion, making them a go-to choice for components exposed to significant wear and tear. That said, the process requires intricate equipment, which can lead to higher initial costs. On the flip side, CVD coatings tend to be more budget-friendly and perform reliably in demanding environments, although they may fall short of PVD coatings in terms of wear resistance and adhesion.

Choosing between these two depends on what your automotive part needs. If durability is the top priority, PVD coatings are the better fit. For those seeking a more economical solution that still holds up in tough conditions, CVD coatings are worth considering. Factors like wear resistance, operating environment, and budget should guide your decision.

When selecting surface finishes for automotive components in Australia, it's crucial to adhere to the country's strict environmental regulations. These rules include mandates for low-VOC (volatile organic compound) and environmentally friendly coatings, designed to support Australia's emissions reduction targets and broader sustainability efforts. From 2025, these standards are set to become even tougher, reinforcing the nation’s environmental commitments.

Australian regulations also prioritise surface treatments that limit the use of hazardous materials. This approach not only simplifies recycling and disposal at the end of a vehicle's life but also aligns with the nation's push towards a circular economy. By promoting sustainable manufacturing methods, these measures aim to lower the overall environmental impact. Make sure the finishes you choose satisfy both functional requirements and these regulatory standards.