As a leading provider of one-stop OEM manufacturing and product development solutions, Mastars recognizes that the principles outlined in "SNAP-FITS FOR ASSEMBLY AND DISASSEMBLY" serve not merely as technical guidelines but as a blueprint for enhancing product performance, reducing costs, and accelerating time-to-market for our clients. Serving industries from automotive to medical devices and household appliances, snap-fit joints perfectly align with our commitment to high quality, cost-effectiveness, and flexible production. Below is a detailed analysis of the document's core points and their practical implications for our manufacturing processes.

The document emphasizes that snap-fit joints represent an "economical and rapid method for joining plastic components," configurable for either easy disassembly or permanent assembly. For Mastars, this versatility directly addresses two critical client needs: cost reduction and design flexibility.

The document identifies "reduced assembly costs" and elimination of "screws, nuts, and washers" as core advantages of snap-fit joints. Within our CNC machining, injection molding, and assembly services, eliminating fasteners reduces material procurement costs and streamlines production workflows. For instance, a household appliance client recently transitioned from screw-fastened plastic components to snap-fit joints, reducing assembly time by 30% and unit costs by 12%—differences that become increasingly significant in high-volume production runs.

Since snap-fit features are "molded as integral components of plastic parts," they integrate seamlessly with our injection molding and 3D printing services. During prototyping phases, 3D-printed snap-fit features enable clients to test assembly mechanisms early, while our injection molding capabilities ensure consistent, high-precision snap-fit production during mass manufacturing.

The document stresses that successful snap-fit design depends on understanding "mechanical stresses, material limitations, and cycle counts." At Mastars, we translate these requirements into actionable steps to prevent common issues like fracture or creep, ensuring long-term performance.

A crucial insight from the document is that strain tolerance varies by material: "unfilled materials can withstand approximately 6% strain, while filled materials can withstand about 1.5%." For our clients, this means:

We also utilize the document's guidance on dynamic strain—using "70% of yield point strain for materials with a defined yield point" and "50% of fracture strain for brittle materials"—to validate designs through finite element analysis (FEA) prior to production.

The document emphasizes that tapered cantilever beams outperform straight beams by "distributing stress more uniformly" and allowing greater deflection. For Mastars, this represents a transformative solution for clients requiring robust, space-efficient designs.

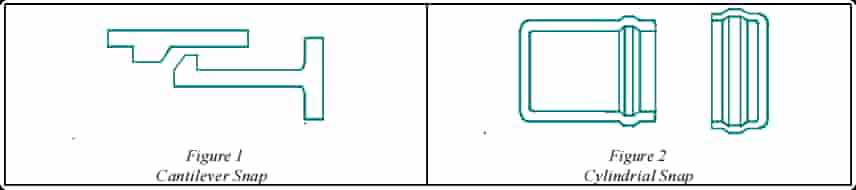

The document identifies two core snap-fit types—cantilever (Figure 1) and cylindrical (Figure 2)—each suited to specific applications. At Mastars, we match these designs to the needs of clients across various industries.

Cantilever beams (such as snap legs) are our preferred solution for components requiring linear assembly, like household appliance panels. We follow the document's assembly force guidelines, using Equation 14 to calculate forces based on friction and assembly angle. For example: For a client's refrigerator door panel, we specified a 30° assembly angle (as recommended in the document) and a friction coefficient of 0.17, resulting in a 7.4-pound assembly force—low enough for manual assembly yet high enough to prevent accidental disengagement.

Cylindrical snap-fits (used in bushings or housings) are critical for our automotive and medical clients. The document notes that cylindrical designs rely on "diametral interference" and while assembly forces are "rough estimates," Equation 32 helps us predict pull-out strength.

The document's user notes emphasize the necessity of "rigorous analysis and prototype testing"—a principle embedded in our workflow. For every snap-fit design:

For Mastars, "SNAP-FITS FOR ASSEMBLY AND DISASSEMBLY" reinforces that snap-fit joints represent more than just fastening methods—they are strategic tools for fulfilling our commitment to "high quality, cost-effectiveness, and timely production." By combining the document's technical guidelines with our manufacturing expertise, we help clients in automotive, medical, and household appliance industries reduce costs, enhance design flexibility, and ensure long-term product reliability.

As OEM requirements evolve, we will continue leveraging insights from such documents to innovate—whether optimizing tapered beam designs for 3D printing or improving cylindrical snap-fits for next-generation medical devices. For Mastars, the future of manufacturing lies in snap-fit joints: efficient, adaptable, and engineered for success.