For Australian design engineers and manufacturing companies committed to competing globally, Rapid Prototyping has long transcended its initial phase of merely "creating a model quickly." It has evolved into a strategic tool integral to the entire product development cycle, directly impacting innovation costs, time-to-market windows, and ultimate success rates.

As a China-based one-stop manufacturing service provider with years of deep industry experience, we understand that high-quality rapid prototyping is the first critical key to unlocking successful mass production.

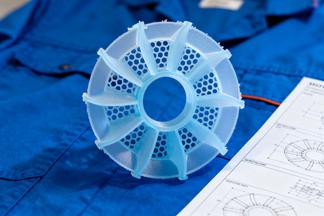

Initial rapid prototyping technologies primarily addressed the need for design "tangibility," aiding teams in visualization and basic verification. However, with the rapid advancement of additive manufacturing and CNC machining technologies, its value has deeply permeated stages such as functional testing, user feedback collection, and even small-batch trial production.

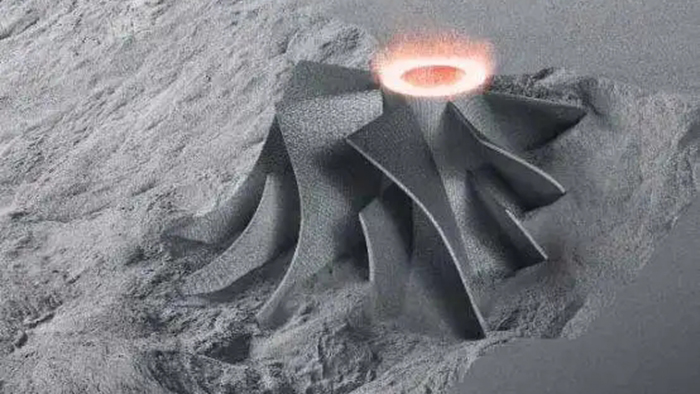

For instance, components produced using Selective Laser Sintering (SLS) technology now possess excellent mechanical properties, allowing them to be used directly for rigorous functional testing. Meanwhile, prototypes created through multi-material 3D printing or high-precision CNC machining can closely mimic the final product in terms of material feel, assembly accuracy, and even optical properties.

This High-Fidelity Prototyping significantly reduces the exorbitant costs associated with late-stage design modifications. As highlighted by Australia's renowned CSIRO in its Industry 4.0 report, "The fidelity of early-stage prototypes is inversely proportional to overall project risk."

For Australian innovators, harnessing the power of rapid prototyping involves not just technological choices but also strategic decisions regarding supply chain partners. While local service providers offer convenience, they often have limitations in technological breadth, cost advantages, and production capacity flexibility. This is precisely where the strategic value of partnering with a leading Chinese manufacturing service provider comes into play.

A Chinese manufacturing partner certified with international quality systems like ISO 9001/AS9100 can offer unparalleled advantages:

Seamless transition from prototyping stages (3D Printing, Vacuum Casting) to subsequent Tooling and Mass Production ensures data consistency and process continuity, drastically shortening the overall time from prototype to market.

Leveraging a mature manufacturing ecosystem, we can provide services ranging from a single proof-of-concept prototype to low-volume production runs of hundreds of units at a more competitive cost, offering robust support for your market testing.

An excellent Chinese manufacturing service provider is not just an order fulfiller but also an expert in Manufacturing Processes. We can offer professional advice on material selection, Design for Manufacturability (DFM) optimization, and post-processing techniques, enhancing the success rate and value of your prototypes.

In the digital age, geographical distance is no longer a barrier to innovation. Equipped with advanced digital manufacturing equipment, stringent quality control processes, and profound project experience, we provide high-quality, high-precision, and highly responsive rapid prototyping services to our Australian clients.

Our goal is not merely to manufacture a part for you but to act as your extended R&D team and reliable manufacturing capacity backup, working together to accelerate the transformation of innovative ideas into successful products.

If you are seeking a comprehensive, reliable, and highly competitive rapid prototyping and manufacturing partner for your next project, please contact us immediately. Our expert team will provide tailored solutions and detailed DFM analysis to help your product win from the very start.