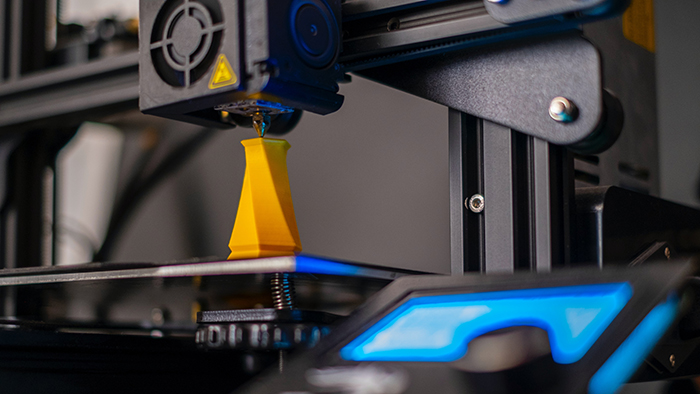

Aluminum alloy is considered as an ideal material for automobile lightweight because of its high specific strength, corrosion resistance and recyclability. 3D printing+aluminum alloy has been used by manufacturers to develop special parts including complex geometry and conformal cooling channels.|rapid prototyping services

However, due to low economic benefits, this technology has not been widely used in automobile production, and casting and mold opening are still the mainstream production methods. How to solve the high cost of 3D printing and really promote its mass production is the opportunity and challenge for 3D printing enterprises.

In order to change this situation, Alloy Enterprises came into being. This 3D printing startup was founded in early 2020, headquartered in Massachusetts, and has received more than 10 million dollars in financing in the past two years. It has developed a new 3D printing process aimed at providing high production of fully dense aluminum components, enabling manufacturers to expand from prototype design to mass production.

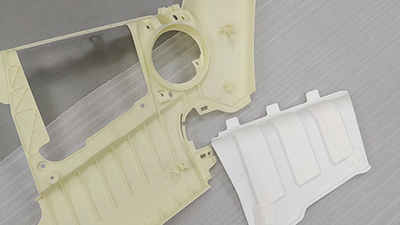

In the opinion of Alloy, there was no real 3D printing process specially designed for aluminum before, so they developed a selective diffusion bonding process specially designed for aluminum in this direction, using proprietary sheet aluminum as raw material instead of powder.

According to the company, this new process will be able to expand production scale, reduce costs and improve safety and ease of use. At the same time, it will help 3D printing get more extensive application in vertical fields such as automobile and industry, and eventually replace traditional processes such as casting.

Selective diffusion bonding is a sheet based process, which belongs to layered solid manufacturing. In terms of materials, the company did not invent a new manufacturing method to produce their new aluminum raw materials, but obtained them by using the same aluminum rolling process as aluminum foil and soda cans. According to Forsyth, founder of Alloy Enterprises, "It is very difficult to start from powder if you want to be truly competitive in mass production. However, it is very critical to adopt aluminum rolling process without reconsidering how to obtain high output and low-cost raw materials."