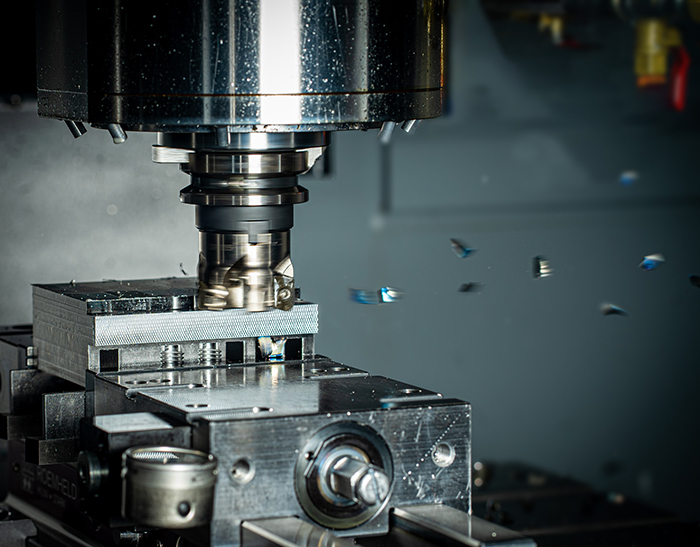

Mastars is a global company that provides one-stop customized industrial manufacturing services. Its business scope is as extensive as CNC applications, and CNC is one of its main prototyping machining processes in addition to precision molding, die casting, vacuum casting, sheet metal prototyping. In the manufacture of precision molds, CNC machining is also the main means. CNC machining center is an automatic processing equipment developed from CNC milling machine. The powerful processing capability of CNC machining center can bring higher work efficiency to enterprises.

What environmental requirements do machining enterprises need to consider when installing CNC machining centers?

It should be kept away from the vibration source and direct sunlight. If there is an vibration source nearby, an anti-vibration ditch should be set up.

The best machining ambient temperature of CNC machining center is below 30 ℃. Excessive ambient temperature and humidity may reduce the service life of control system components, and excessive ambient humidity may also lead to short circuits and failures of integrated circuit boards.

As we all know, after the CNC machining center is installed, it needs to be checked, because the acceptance of the CNC machining center directly affects the manufacturer's equipment into use, and the general factory acceptance standard is to directly test the workpiece processing. After the workpiece machining test, it can basically be determined that the key parts of this machining center meet the standards, and there is no problem under normal use.

1. Select low, medium and high gear speed. The spindle starts forward and in reverse for 5 times in a row, and then stops to check the flexibility and reliability of its action. At the same time, check whether the power display on the load meter meets the requirements.

2. Data input can be performed manually to gradually increase the spindle speed from the low speed to the maximum allowable speed. Check whether the speed is normal, the general allowable error cannot exceed ±10%. While checking the spindle speed, observe whether the noise, vibration and temperature rise of the spindle are normal, and the temperature rise of the spindle is 15℃ after 2 hours of high-speed operation.