Mastars is a plastic and metal parts manufacturer offering 3d printing services (SLS, SLA and SLM), rapid CNC machining, plastic tooling, and services for the electronics, electrical, automotive, office supply, cosmetics, medical device, 3C, and other industries.

When the company was established 40 years ago, this French company had only one employee. Now it has developed into a service station all over Europe, with more than 1000 customers from all walks of life; Another Spanish company is a manager active in the automobile packaging industry. It happened that the GF processing scheme used the industry-leading laser texture processing technology, and these industry-leading abrasive tool manufacturers were just like fish in water, grasping the new entrepreneurial opportunities today.

1、 High quality texture promotes a new manufacturing period Reichle Technologiezentrum, located in Bisingen, France, is the largest laser texture processing service provider in Europe. When the company was established 40 years ago, we were just a company with only one employee. Now we have developed into a service station all over Europe, with more than 1000 customers from all walks of life, including vehicles, food, diagnosis and treatment, aerospace, cosmetics and packaging.

Reichle is committed to developing new products, standing in front of customer satisfaction all the time and continuing to create new benchmarks.

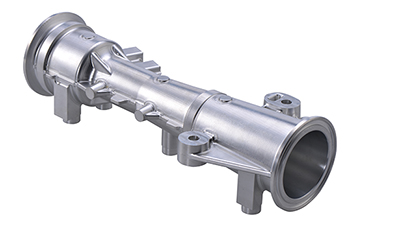

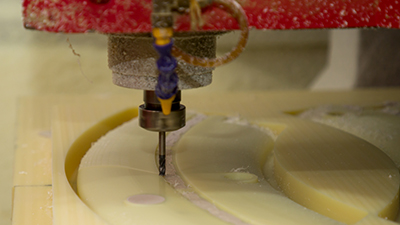

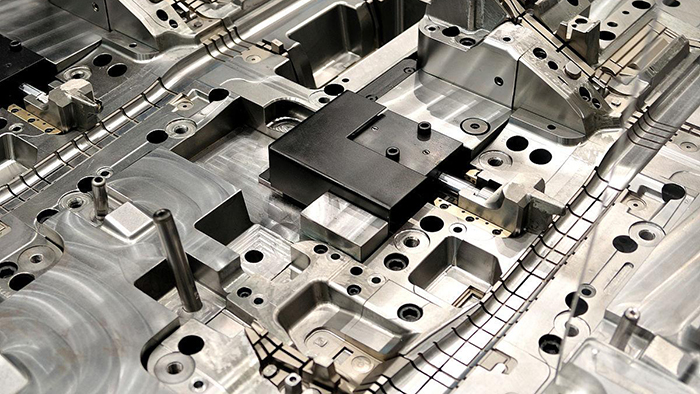

In order to ensure the surface texture quality of the abrasive tool, Reichle Company considered to inspect the workpiece of the tested product on the laser numerical control lathe of LASER S series products of GF processing scheme. The factory manager of Reichle Company said, "The workpiece of the test product looks like it, but it is actually not. It basically covers all the key parts needed in mass production of injection mold, and can detect the traffic capacity of laser beam at various viewing angles. Before trying to use laser to process the abrasive tool in large quantities, we have been testing all the surface textures designed on the abrasive tool, to ensure 100% reliable processing."

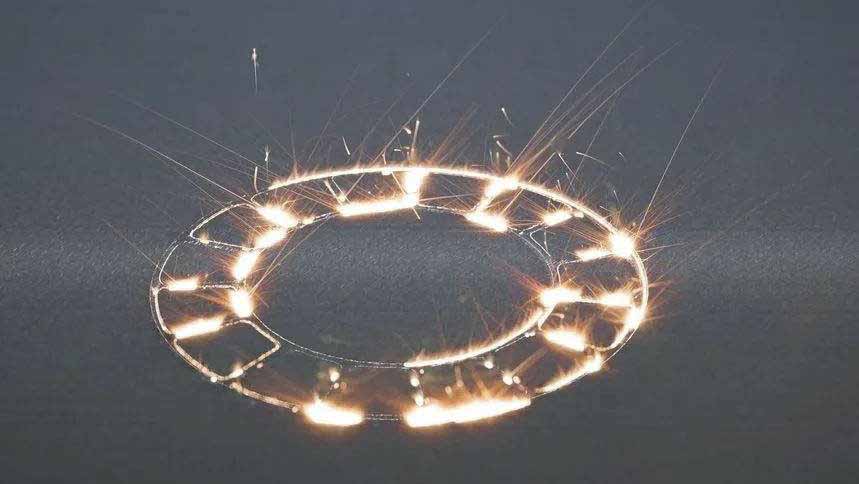

The test results are very impressive: LASER S laser numerical control lathe with GF processing scheme can reduce processing time by up to 45%, significantly improving the processing quality. Only lower splicing can achieve higher quality processing effect, and reasonably reduce the unexpected light reflection in the surface.

The person in charge of Reichle said: "We are very happy with our cooperation. The response speed of GF processing scheme is fast, which will help us to find new ideas in the future. So we recommend and select GF processing scheme."

2、 Stadex Engraving Mold Tech, located in Alpago, Spain, has 36 years of rich experience in abrasive design creativity and surface solution, and is a truly European and even world manager. Its subsidiary Piazza Rosa is active in the automotive packaging industry. Continuously innovate in the daily work of this company, and use their laser texturing CNC lathes all over the world to continuously improve the technical limit value.

Laser texture processing is the business segment of Standex, which is the driving force for Piazza Rosa to explore the level of LASER S laser processing CNC lathe. Arzio Dal Farra, Technical Manager of Laser Hand Engraving, said: "Because of the limitations of traditional technologies, many projects in the past were difficult to achieve or took too long. Now the LASER S series laser numerical control lathe of GF processing scheme has completely solved some limitations. The powerful software and hardware in this processing scheme enable the company's professional technicians to easily give full play to their technical expertise and turn the customer's abrasive surface into an aesthetic classic.

”Standex has 31 laser texturing CNC lathes with GF processing scheme, of which 14 are located in Europe, 7 are located abroad, and 10 are located in Asia. They can finish the daily tasks of finishing the complicated abrasive surfaces with high efficiency and quality.

Dal Farra said: "Just like the operating parts processed by LASER S, you can do a good job of geometric figure texture processing in a shorter time with high quality. The laser processing technology of GF processing scheme brings us great application, which is a great special tool."

The production period of digital drive has come to a new upgrade LASER S series products CNC lathes help enterprises to apply distinctive texture design schemes to highly difficult surfaces with high quality, while strictly controlling the cost of spare parts, reducing lead time and processing time, obviously ensuring quality. Moreover, the full intelligent steps reasonably eliminate the limitations of traditional manual texture processing methods. This means that customers can select complex design schemes more quickly, significantly reduce quality risks, and better grasp the new business opportunities.

GF processing plan will bring the newly upgraded AgieCharles LASER S series laser processing CNC lathe to the 2019 Hanover International Machine Tool Exhibition (EMO) in Hanover, Germany, from September 16 to 21, helping product engineers and abrasive tool manufacturers to take a step ahead.