Mastars' rapid prototyping service can provide various 3D printing prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

Previous chapter: Talk about common

3D printing technologies 3. Today we will introduce common 3D printing technologies 4.

SLM technology

SLM(Selective Laser Melting) can directly form metal parts that are close to full density. SLM technology overcomes the complex process of manufacturing metal parts with SLS technology.

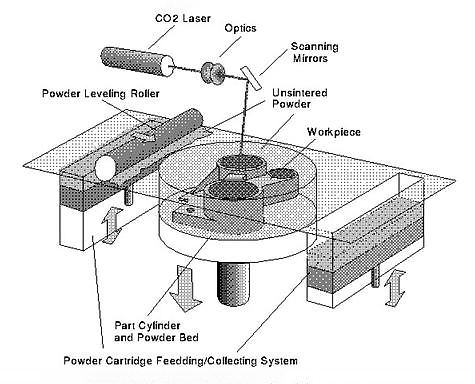

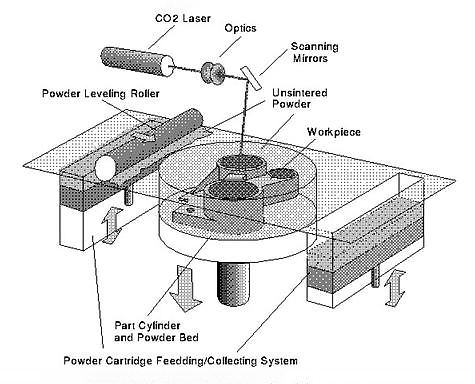

The principle of SLM process

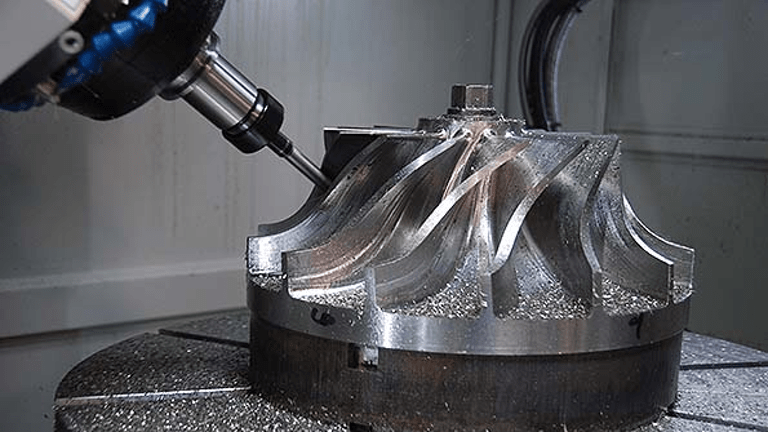

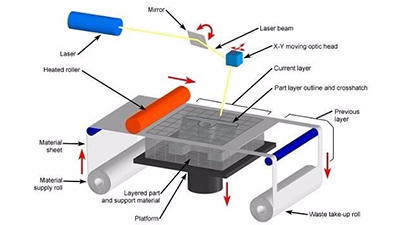

SLM is a technology in which metal powder is completely melted under the heat of a laser beam, and then formed by cooling and solidification. Therefore, the laser power density required by SLM is significantly higher than that of SLS, and the spot is focused to dozens of microns. The production process of SLM and SLS is very similar. First, the powder is evenly spread to the laser processing area by a scraper, and then the computer will control the laser beam to selectively melt the metal powder according to the previously obtained laser scanning information through the scanning mirror, and get the same entity as the current two-dimensional slice graph. Then the lifter in the forming area is lowered by one layer thickness, and the above process is repeated to form a three-dimensional entity that is the same as the model layer by layer.

However, the SLM process generally needs the addition of support structures, and its main functions are as follows:

1. Undertake the next layer of unmolded powder layer to prevent the laser scanning to the excessively thick metal powder layer and collapse.

2. After the powder is heated, melted and cooled during the molding process, there is shrinkage stress inside, which causes the parts to warp, etc. The support structure connects the formed part and the unformed part, which can effectively suppress this shrinkage and keep the stress balance of the molded part.

Advantages of the SLM process:

1. The terminal metal product is directly driven by the three-dimensional design model, and only needs a simple post-processing or surface treatment process, which saves the intermediate transition and saves the time for opening and making the mold.

2. The density of standard metals processed by SLM process exceeds 99%, and the good mechanical properties are comparable to traditional casting and forging processes.

3. It can process metal parts with high dimensional accuracy (up to 0.1mm) and good surface roughness (Ra is 30-50μm).

4. SLM is suitable for forming workpieces of various complex shapes, such as parts with complex inner cavity structures and individual needs in the medical field, which cannot be manufactured by traditional methods.

5. The types of machinable materials continue to increase, and the processed parts can be welded later.

Disadvantages of SLM process:

1. The price is expensive and the speed is low.

2. The precision and surface quality are limited, which can be improved by post-processing.

Application range of SLM process

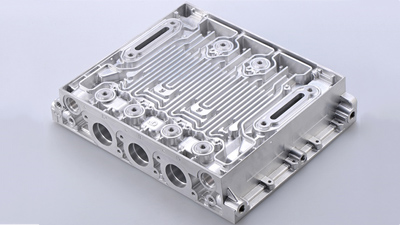

1. Processing standard metal appearance, assembly, functional prototype.

2. Support parts, such as fixtures, fixed devices, etc.

3. Small batch parts production.

4. Injection mould.

Mastars' industrial prototype service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture, stage lighting and outdoor sports, etc.

Mastars has a professional team of engineers and service teams, adhering to the spirit of craftsman in industry, to provide comprehensive solutions for your product development and production. At the same time, our company meets the customized order requirements of customers in various industries with the tenet of multi-variety, small batch and fast delivery.

So if you have any needs for prototype parts or mass production, please feel free to contact us, we are the most suitable partner that you have been looking for.

In the next chapter, we will continue to talk about common 3D printing technologies 5.

Mastars Industries CO., LTD

Website: www.mastars.com

• Email: marketing@mastars.com

• Tel: +86 755-88210689

• Fax: +86 755-8821 0685

• Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China(518104)