Writing in the latest issue of

Nature Materials, a team of Australian engineers say they have used 3D printing for the first time to obtain the highest specific strength titanium alloy to date, a major leap forward for the aerospace, defense, energy and biomedical industries. |

metal 3d printing services

Cutting-edge 3D printing technology can be used to produce ultra-high-strength commercial titanium alloys with unprecedented mechanical properties, according to new research from Monash University.

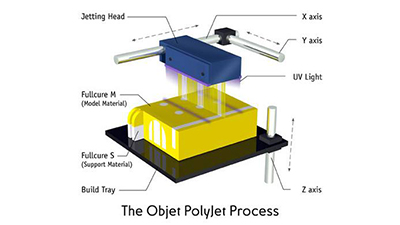

The researchers explained: "Titanium alloys require complex casting and thermo-mechanical processing to achieve the high strengths required for some critical applications. We have found that additive manufacturing techniques such as

3D printing can take advantage of their unique manufacturing processes to produce high-quality titanium alloys in commercially available titanium alloys. Super strong and thermally stable components are created within the alloy.

In the latest study, the research team achieved a tensile strength of over 1600 MPa after a simple heat treatment of a commercial titanium alloy, the highest specific strength of any 3D printed metal to date. Structural materials with excellent performance and wide application in many fields have paved the way.

Over the past decade, 3D printing technology has ushered in a new era of metal fabrication due to its ability to create parts with virtually any geometry. Titanium alloys are currently the main 3D printed metal parts used in the aerospace field, but most commercial titanium alloys made with 3D printing technology cannot achieve satisfactory properties, so they cannot be used in certain fields or are not satisfactory, especially It is their lack of strength at room temperature and high temperature.

The researchers said: "The latest research provides a completely new method for precipitation strengthening of commercial alloys, which can be used to produce real parts with complex shapes, which can be used in load-bearing applications, where no titanium alloys have been used to date. In addition, We did this by 3D printing coupled with a simple heat treatment, which also means that the process costs for the latest technology are significantly lower compared to other materials of similar strength.