Mastars offers

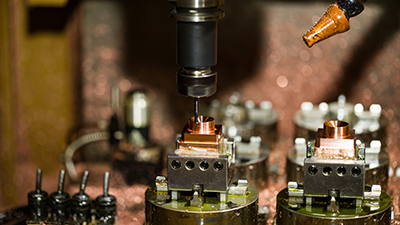

cnc prototype machining,

rapid cnc service.Gears are the core transmission components in automobiles, and their quality can directly affect the vibration, noise and reliability of the entire vehicle. Gears can be CNC machined to ensure the quality and accuracy of gears. The order of

CNC machining of gears should be done according to the principle of base milling first, coarse then fine milling, primary then secondary.

Machine each outer circle first, paying attention to the separation of rough and finish machining. Rough machining is followed by quenching and tempering heat treatment process, and quenching is followed by finishing machining. The processes are separated to ensure the fineness of the final primary surface so that it will not be affected by the other surfaces when machining.

After the completion of semi-finishing of each outer circle, rough machining of the gear tooth profile begins. Because of the heavy and difficult machining of the tooth profile, it is machined with appropriate allowances. This can improve the positioning reference for finishing. Tooth shape finishing should be arranged after all surfaces of the outer circle of the part are machined to eliminate the deformation caused by local quenching of the tooth shape.

To ensure the accuracy of the workpiece and avoid reducing the rigidity of the workpiece. Cylindrical surface processing should be machined first large diameter cylindrical surface, after processing small diameter cylindrical surface.

The processing of the keyway on the gear should generally be arranged in each outer circle after finishing turning or before finishing grinding, otherwise milling processing keyway, intermittent cutting vibration will affect the quality of processing, but also damage the tool; keyway size is also difficult to ensure, so as not to damage the accuracy of the main surface