Everything You Should Know About Living Hinge Plastic

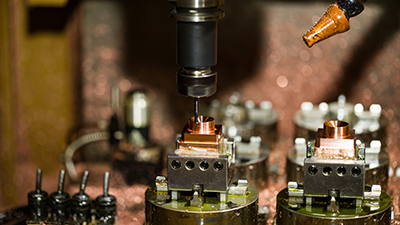

we provide rapid prototyping services and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Metal 3D printing is becoming a common manufacturing process in most industries. This is a guide to the metal 3D printing process

Metal 3D printing prototype technology

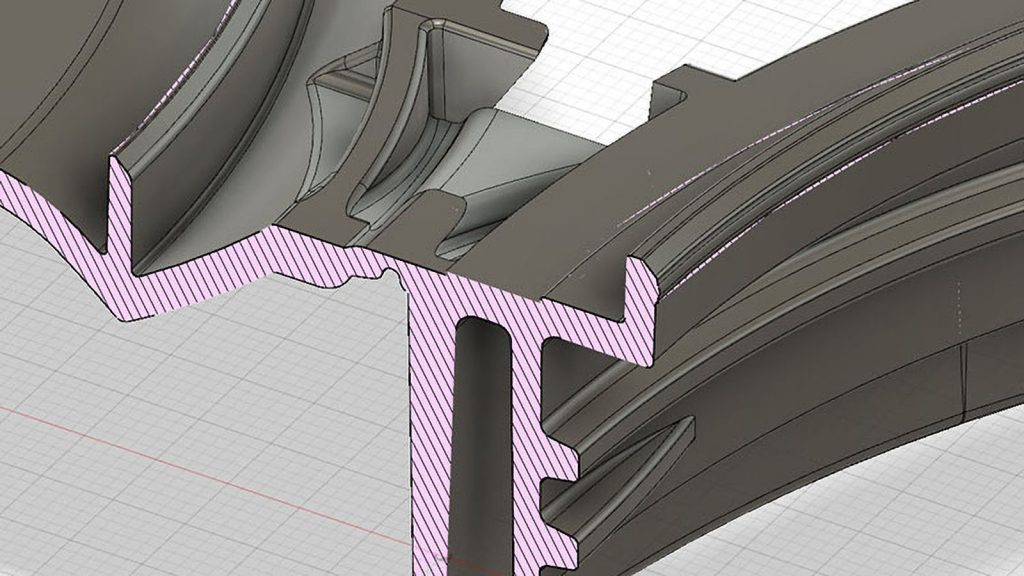

The working principle of metal 3D printer is the same as that of other 3D printers. Basically, it builds parts by adding materials layer by layer. This is after referring to CAD files or 3D designs. Three common technologies used in Metal 3D printing are DMLS / SLM, metal extrusion and adhesive spraying.

DMLS / SLM Metal 3D printing prototype

SLM stands for selective laser melting. This is an example of a rapid metal prototyping method. Metal 3D printing method melts and fuses metal powders with the help of high-power density laser. It performs this operation layer by layer and finally forms a part. However, DMLS represents direct metal laser sintering and has some similarities with SLM. The only difference is the laser temperature. DMLS does not completely melt the metal powder.

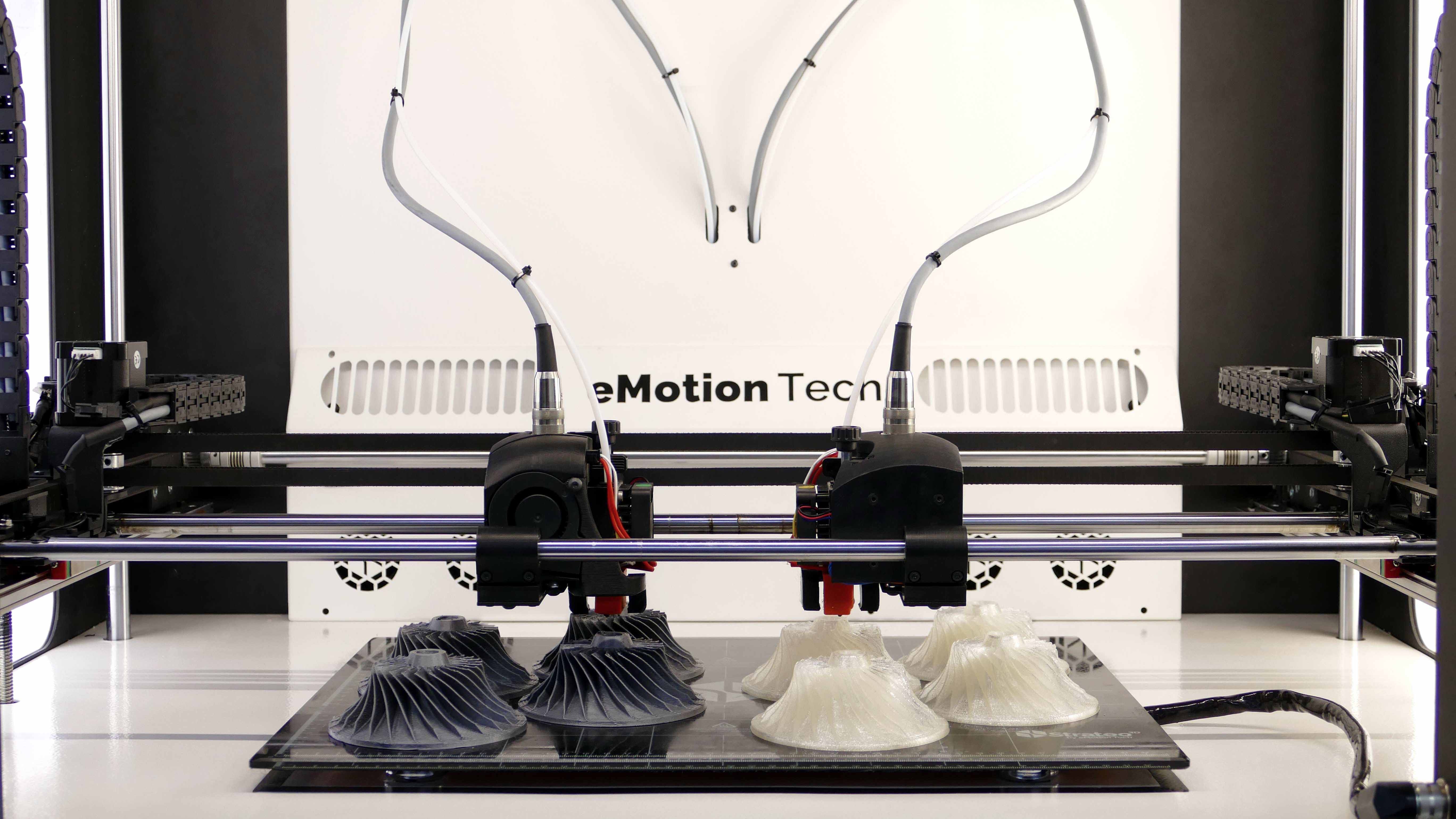

Metal extrusion

This process is relatively new for the additive prototype manufacturing industry. It has some similarities with the same popular FDM technology. First, we heat the filament, then extrude it through the nozzle and deposit it layer by layer. Filaments contain metal particles and thermoplastic materials. Finally, to make fully functional metal parts, we need to carry out post-treatment. Sintering, boning and other methods

Mastars Industries CO., LTD

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China