In order to achieve a significant reduction in carbon emissions per vehicle by 2030, the BMW Group is once again innovating in the development of innovative materials. Especially with the launch of its all-electric vehicle platform

Neue Klasse, the BMW Group is promoting the use of secondary materials.|

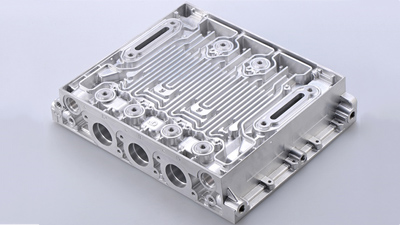

rapid prototyping services

In order to reduce carbon, which environmentally friendly materials does BMW love? It is understood that BMW has set new standards for innovative environmentally friendly materials that follow the four dimensions of the circular economy - namely RETHINK, REDUCE, REUSE and RECYCLE.

Integrating natural materials

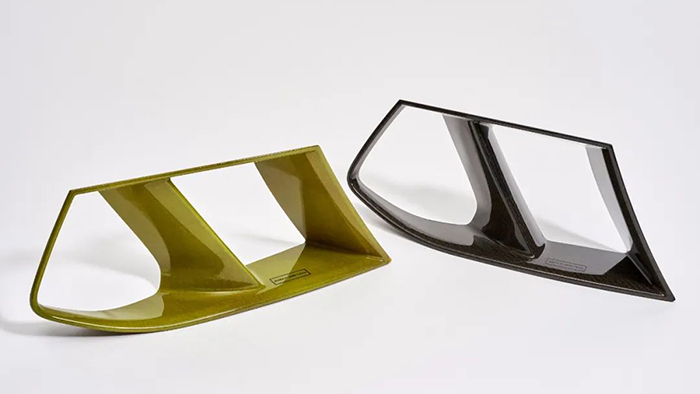

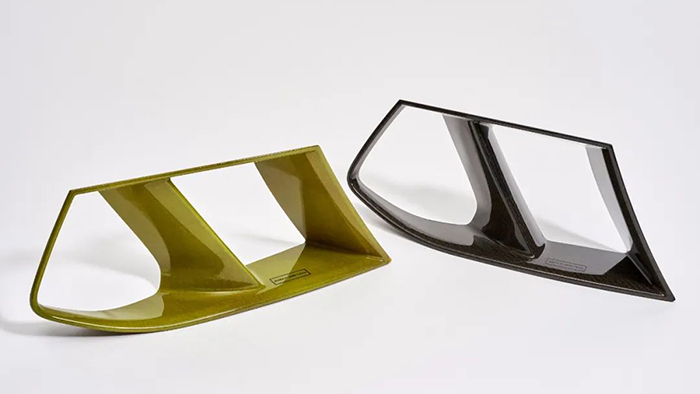

For many years, the BMW Group has been using renewable raw materials in its vehicles - for example, in door trim panels that use natural fiber mats paired with a plastic substrate to provide the necessary stability. Renewable raw materials such as natural fibers are not only 30 percent lighter than plastic alternatives, but their carbon emissions are calculated to be negative because they absorb carbon dioxide and release oxygen during the growth phase.

Recognizing this potential of natural fibers, BMW and its partner companies have systematically developed fibers such as flax, providing them with a natural fiber lattice structure. These support structures, can maintain their mechanical properties and achieve weight reduction by reducing the amount of material required.

Wood can be used as a renewable raw material in many different applications. The BMW Group is also working on pioneering wood foams with an open-cell structure consisting of finely ground wood particles. The resistance of the foam comes from the binding force of the wood itself, which makes it possible to eliminate the need for synthetic adhesives. This foam thus consists of 100% renewable raw materials and could replace acoustic foams in the future.

Recycled plastic: smart and environmentally friendly

The BMW Group is already using up to 100 percent recycled plastics in its thermoplastic components and is working with leading plastics manufacturers to further develop recycled plastics and bioplastics with a significantly lower carbon footprint.

In addition to recycled plastics, the company is using bio-based plastics and plastics reinforced with natural fibers such as cellulose, flax, wood or bamboo to reduce the percentage of new petroleum-based plastics. Its goal is to use thermoplastics containing an average of 40 percent recycled material by 2030.

Innovative leather can reduce carbon emissions by 45%

New vegan and resource-efficient leather alternatives are another important element of the BMW Group's research. Compared to today's PVC synthetic leather, synthetic leather with bio-based raw materials, 100 percent recycled polyester textiles and cork pellets can reduce CO2 emissions by up to 45 percent.

In cooperation with the start-up Adriano di Marti S.A. de C.V., the BMW Group is working on a sustainable cactus material. deserttex is made from crushed cactus fibers and a bio-based polyurethane matrix. Another potential alternative to leather is the fully recyclable Mirum, which mimics all the properties of traditional leather, yarn and foam. The BMW Group's equity investment in the startup Natural Fiber Welding opens up new possibilities for the development and implementation of plant-based material options.