5 Reasons Why plastic injection moulding is So Effective

Plastic injection moulding is one in all the foremost common and versatile strategies for mass manufacturing plastic elements, because it has multiple benefits over different strategies of plastic moulding.

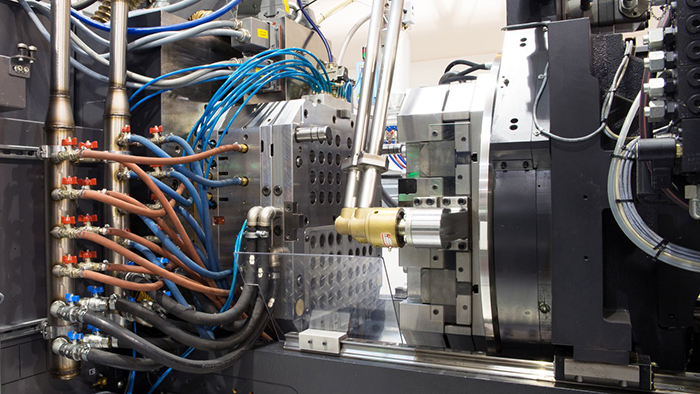

Involving feeding plastic material into a heated barrel, the plastic is mixed then crystal rectifier into a mould cavity, wherever it takes form and hardens into the ultimate product.

Plastic injection moulding is employed during a vast sort of product, however why is it therefore common as a technique?

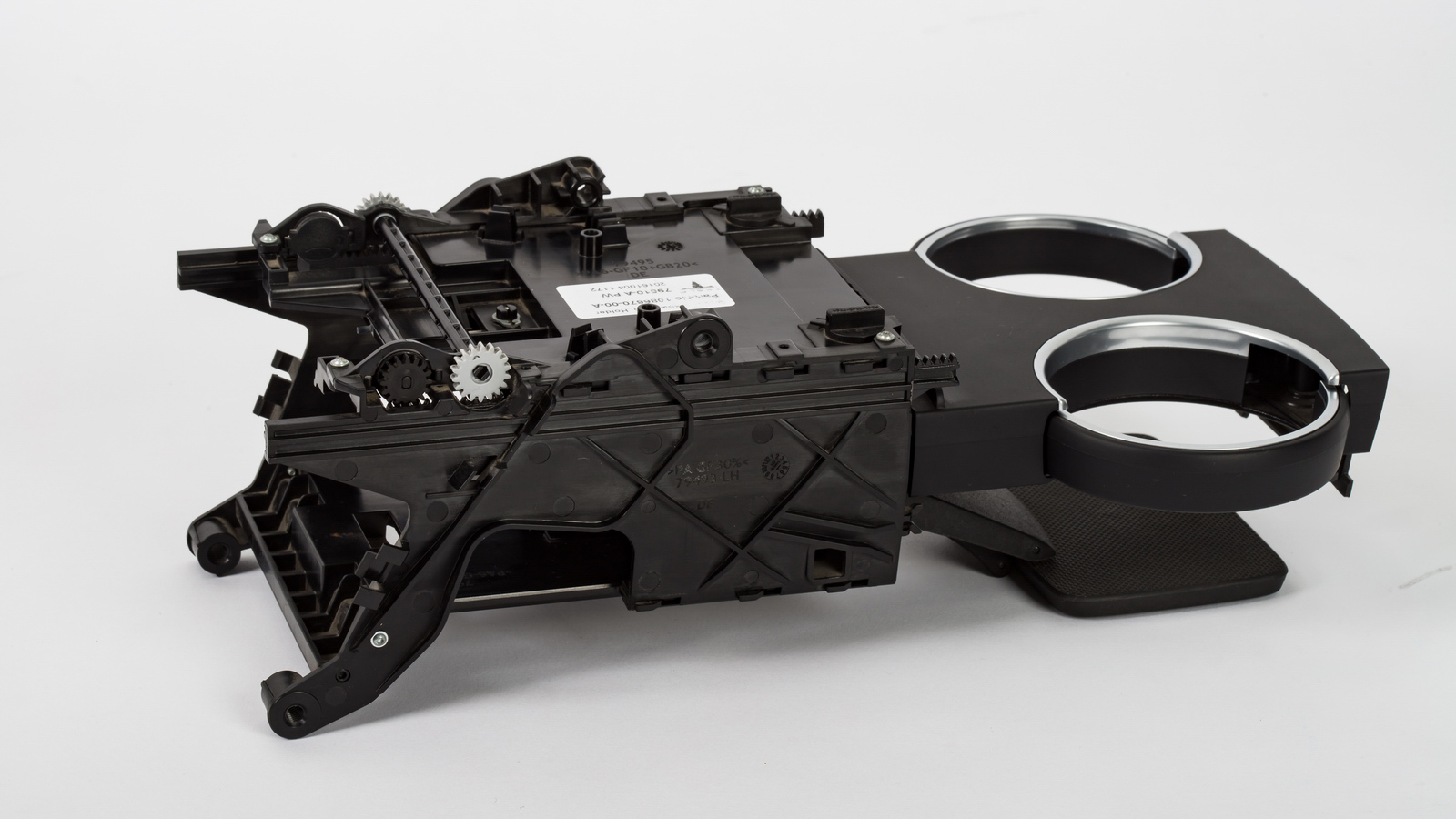

1. Details and complicated shapes

Due to the massive pressure (more than the other plastic moulding method) that plastic injection moulding causes, the fabric is ironed overly laborious against the mould, which means that terribly specific details and complicated pure mathematics is cleanly integrated into the look.

2. Speed

The high output rate of the plastic injection moulding method makes it extremely popular. each machine is completely different, but typically solely regarding fifteen to thirty seconds pass between cycle times!

3. Low labour prices

Plastic injection moulding instrumentality typically runs with a self-gating, automatic tool to stay operations efficient and production in progress, requiring token management.

4. Strength

Fillers among the injection moulds mean that the density of the plastic is reduced whereas it’s being moulded, serving to add bigger strength to the finished product. In fields wherever strength may be a very important property to the plastic half (e.g part or automotive), plastic injection moulding offers the simplest possibility.

5. Multiple styles of plastic

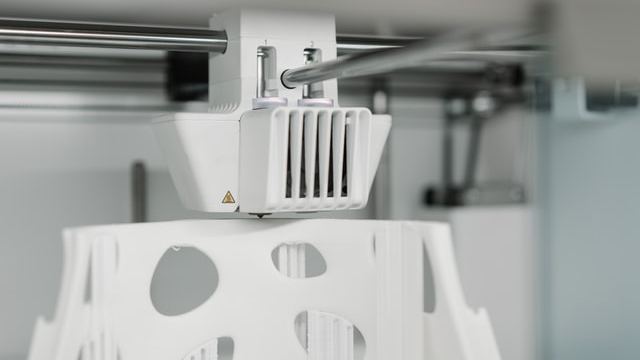

Through co-injection it’s attainable to integrate over one form of plastic into the merchandise at the same time with its production. This takes away the fear regarding employing a specific form of plastic.

The bottom line is that our plastic injection moulding manufacture creates a large vary of product for all industries during a thorough, precise and efficient manner. With our experience and instrumentality, the product hardly need any work once the assembly, because of their finished look once they’re ejected from the injection moulds.

Mastars Industries CO., LTD

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China